Wire Container

What Is Wire Container

Wire container, also known as warehouse storage cage, is a very important kind of logistics container in storage and transportation. The main components of the storage cage include the cage mesh and the chassis. The cage mesh is welded by high-strength steel wire to form a fixed grid structure. The chassis is usually welded from U-channel steel to provide stable support for the storage cage. In addition, the foot height of the storage cage is generally 100mm or 120mm, which is convenient for stacking and handling.

Features of wire container

Fixed storage capacity: The storage cage has a fixed storage capacity, making the storage of items more orderly, standardized, easy to manage.

Storage cages are designed so that items can be stacked neatly, avoiding the confusion and damage that can be caused by traditional stacking methods.

Clear storage: Due to the transparency or clear identification of the storage cage, the stored items are clear at a glance, which is easy to inventory and management.

High space utilization: The storage cage can effectively use the storage space, improve the space utilization rate, and reduce the storage cost.

Strong and durable: Storage cages are usually made of high-strength steel wire welded, with strong and durable characteristics, can withstand greater weight and pressure.

Convenient transportation: The storage cage has a standardized size and shape, which is easy to transport and load and unload, reducing transportation costs.

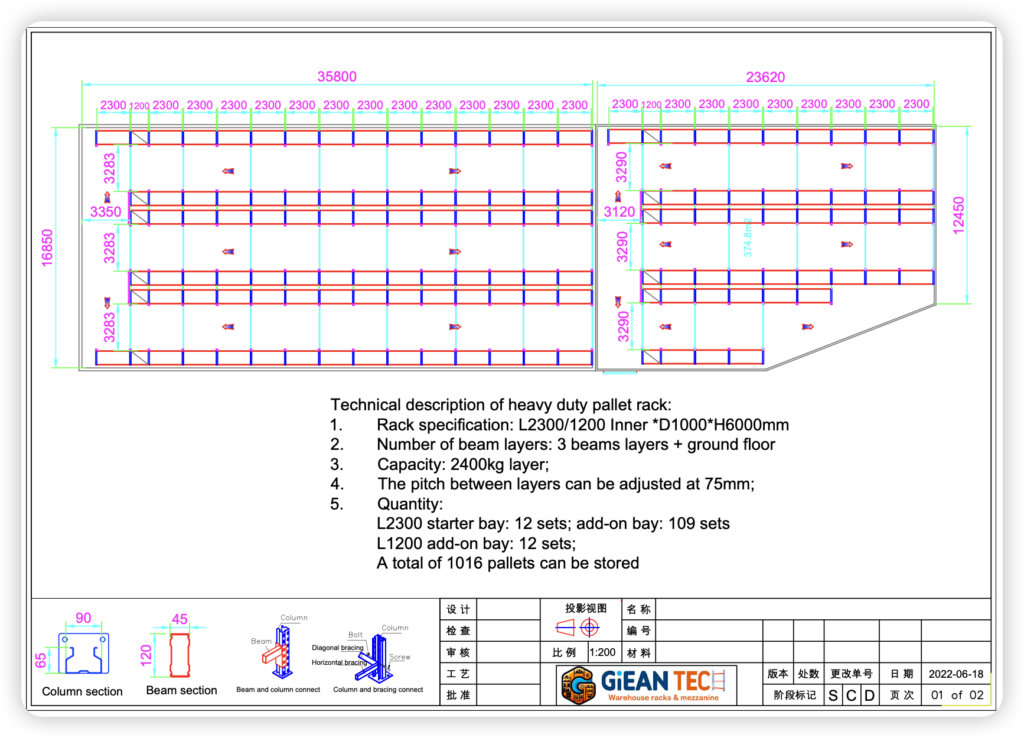

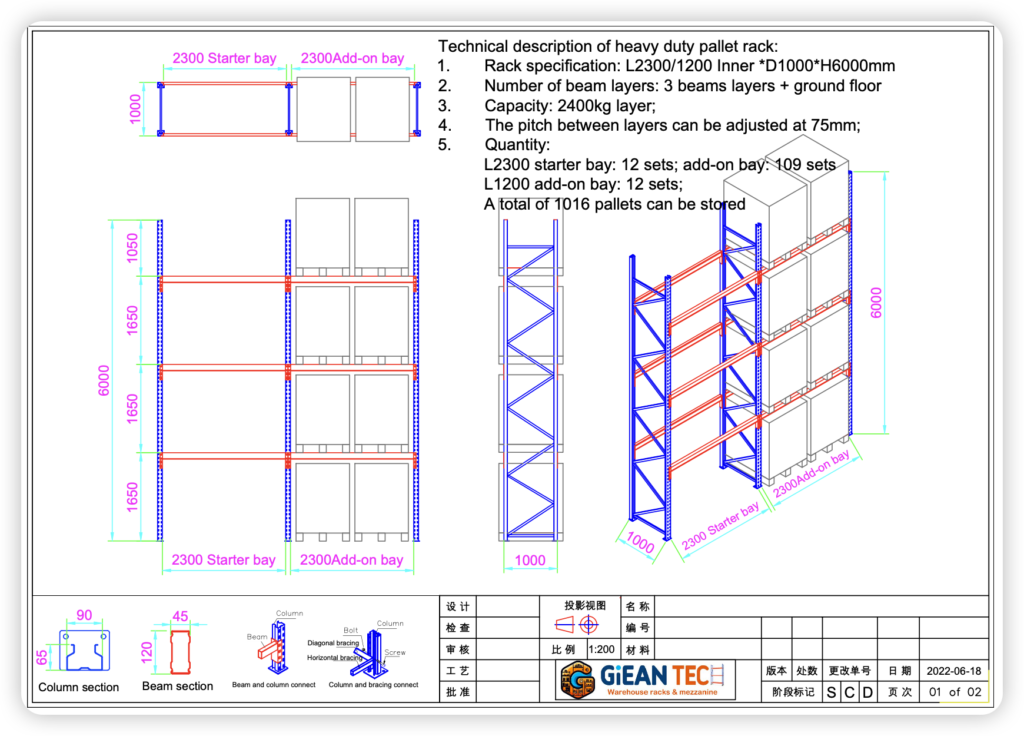

The process of Giean warehouse storage solution drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

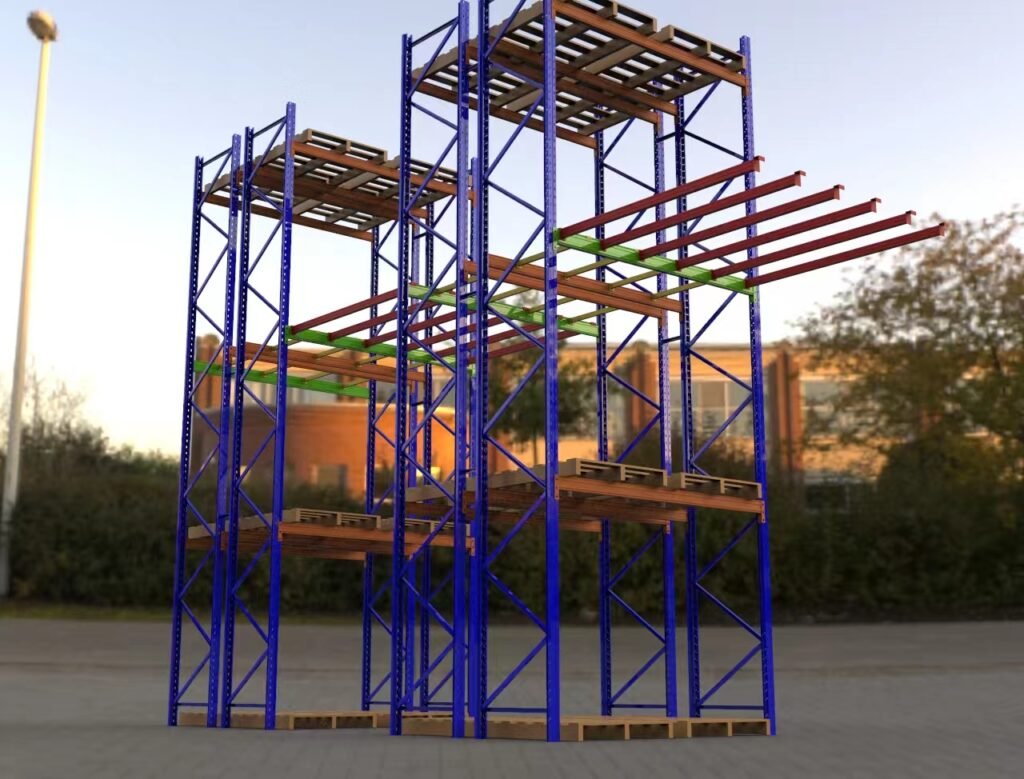

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Classification Of Wire Container

Folding wire container: can be freely folded, when not in use can be folded storage, saving warehouse space. The design of the folding wire container is also easy to access items at any time, avoiding the trouble of flipping.

Non-folding wire container: After special reinforcement treatment, the weight is large, generally can be stacked more layers. Suitable for applications requiring greater weight and pressure.

Traction wire container: The traction device is installed at the left and right position of the wire container, and the caster is added, which can easily flow freely in the smooth ground.

Castor wire container: equipped with wheels at the bottom, flexible and lightweight operation, more suitable for production workshops and other occasions that need to move frequently.

Application Of Wire Container

Storage and handling: Storage cages can be used to store and handle various raw materials, parts and finished products. Its rugged design ensures the safety of items during storage and transportation.

Production line management: In the automobile, motorcycle, bicycle and other transportation manufacturing industry, as well as stamping, die casting, hardware, mold, machinery manufacturing, metal products, toys, lighting, plastic hardware and other industries, storage cages are widely used in the production line material management and storage of finished products.

Cargo storage: Logistics centers and distribution centers often use storage cages to store goods for sorting, packaging and distribution.

Transport: Storage cages can be used with logistics equipment such as forklifts and trucks to improve the efficiency and safety of logistics operations.

Shopping malls and supermarkets: Storage cages can be used for the display, promotion and storage of goods in supermarkets, which is convenient for customers to buy and staff management.

Highways, stations and docks: In these transportation hubs, storage cages are used to store and transport all kinds of goods, ensuring smooth logistics.

Tobacco Postal: The tobacco and postal industries also frequently use storage cages to store and transport various items and improve logistics efficiency.

Frequently Asked Questions About wire container

Wire containers offer advantages such as durability, stackability, ease of handling, high space utilization, and visible inventory management. Compared to traditional storage methods like cardboard boxes or wooden crates, wire containers can be reused, reducing packaging costs and environmental impact. Additionally, their standardized design facilitates efficient inventory management and improves work efficiency.

Wire containers come in various sizes and load capacities tailored to customer needs. Common sizes include standard and special dimensions to accommodate different storage requirements. Load capacity depends on the material and structural design of the wire container, typically capable of meeting the needs of most industrial and commercial applications.

Wire containers are available in materials such as metal (steel, stainless steel, aluminum alloy), plastic, and composites. Metal wire containers are durable and have high load-bearing capacity, suitable for heavy-duty industrial applications. Plastic wire containers are lightweight, easy to clean, and cost-effective, suitable for light industry and food sectors. Composite wire containers combine the advantages of metal and plastic, offering better corrosion resistance and weatherability.

Yes, wire containers are designed to be easy to clean and maintain. Metal wire containers can be cleaned using brushes or high-pressure water jets, while plastic wire containers can be wiped down with a damp cloth. Additionally, the standardized design of wire containers makes it easy to replace parts, extending their lifespan.

Wire containers can be used in conjunction with logistics equipment such as forklifts, elevators, and conveyors for rapid handling and stacking of goods. The bottoms of wire containers are typically designed with forklift pockets for easy insertion and handling by forklifts. Additionally, their stacking design allows them to be efficiently stacked on shelves, maximizing space utilization.

Wire containers contribute to environmental protection by being reusable packaging containers that reduce the generation of packaging waste. Furthermore, metal wire containers can be recycled, further reducing resource waste. Therefore, using wire containers is an environmentally friendly storage solution.

Customization services for wire containers typically include size customization, load capacity customization, color customization, and label customization. Customers can choose the appropriate customization services based on their needs to meet specific storage and logistics requirements.

When choosing the right wire container supplier, customers should consider factors such as the supplier’s reputation, product quality, pricing, delivery time, and after-sales service. It is recommended to conduct market research before selecting to understand the advantages and disadvantages of different suppliers and make an informed decision. Additionally, customers can request samples from suppliers for testing and evaluation to ensure that the selected wire container meets their needs.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!