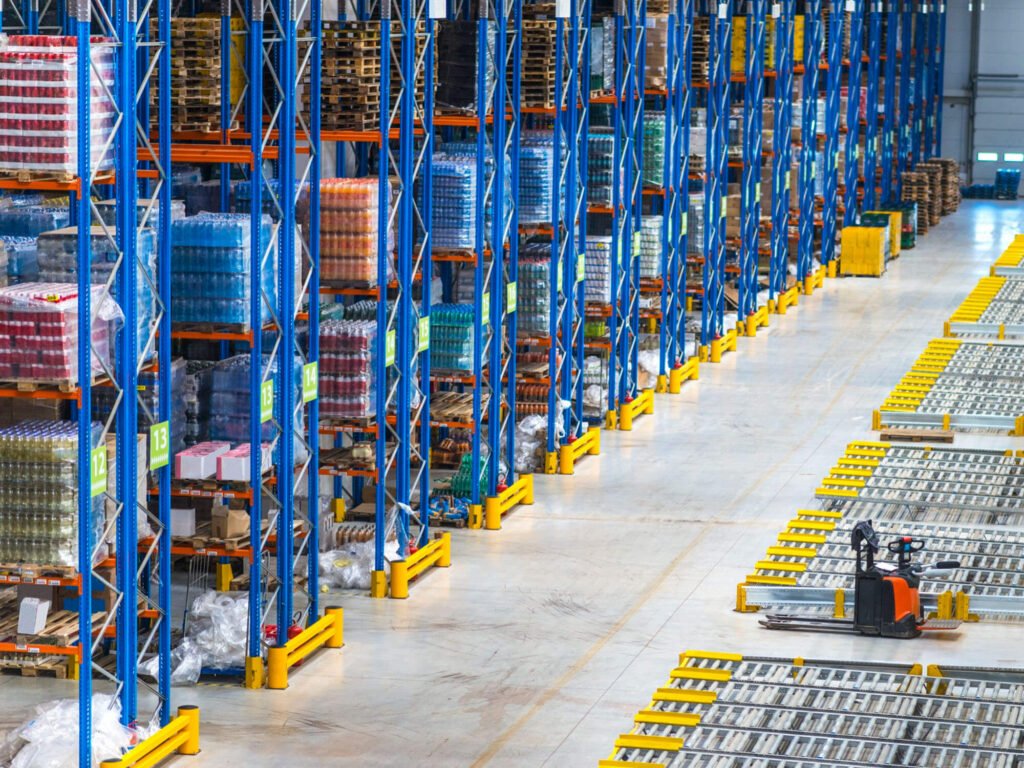

Warehouse Racking System

Warehouse Racking System Definition

A warehouse rack system is a structured framework designed for the efficient storage and organization of goods within a warehouse. These systems come in various forms, including selective racks, drive-in racks, and pallet flow racks, each catering to different storage needs and inventory turnover rates. By optimizing vertical space and facilitating easy access to products, warehouse racks enhance operational efficiency and streamline inventory management. They accommodate a wide range of products, from bulk items to smaller goods, and are essential for maximizing storage capacity while ensuring safety and accessibility in warehouse environments.

Types Of Warehouse Racking Systems Classification

Selective Pallet Racking System

A selective pallet rack is a versatile storage system designed to provide easy access to individual pallets. This system allows for a wide range of pallet sizes and weights, enabling efficient inventory management. Each pallet is directly accessible without needing to move others, making it ideal for facilities with diverse product lines. Selective pallet racks optimize space utilization while facilitating quick retrieval and replenishment, enhancing overall warehouse efficiency and productivity.

Teardrop Pallet Racking System

A teardrop pallet rack is a popular storage solution characterized by its distinctive tear-drop shaped holes, allowing for easy assembly and adjustment of beams. This system provides high-density storage while ensuring direct access to pallets. Its design accommodates various pallet sizes and weights, making it versatile for different warehouse needs. The tear drop configuration enhances stability and safety, facilitating efficient inventory management and quick retrieval, ultimately optimizing warehouse operations and space utilization.

Cantilever Racking System

A cantilever rack system is a specialized storage solution designed for storing long, bulky items such as lumber, pipes, and furniture. This system features vertical columns with extending arms, allowing for unobstructed access to products from both sides. Cantilever racks maximize vertical space and provide flexibility in storing varying lengths and weights. Ideal for warehouses and industrial environments, they enhance efficiency by facilitating easy loading and unloading while ensuring stability and safety for large, heavy items.

Mold Racking System

A mold rack system is a specialized storage solution designed for the safe and organized storage of molds and tooling components in manufacturing environments. These racks feature adjustable shelves or compartments that accommodate various mold sizes and weights, optimizing space utilization. Mold racks enhance accessibility, allowing for quick retrieval and efficient inventory management. Their sturdy construction ensures the safety of valuable molds while minimizing the risk of damage. Ideal for production facilities, mold racks contribute to streamlined operations and improved workflow in manufacturing processes.

Stacking Racking System

A stacking rack system is a versatile storage solution designed for the efficient organization and stacking of various products. These racks consist of a framework that allows items to be stacked vertically, maximizing vertical space while maintaining accessibility. Ideal for warehouses and distribution centers, stacking racks accommodate different product sizes and weights, making them suitable for bulk storage. Their design enhances operational efficiency by facilitating easy loading and unloading, improving inventory management, and allowing for quick access to stored goods.

Drive In Drive Through Pallet Racking System

A drive-in pallet rack is a space-efficient storage system that allows forklifts to enter the rack structure for direct access to pallets. This design maximizes storage density by using a last-in, first-out (LIFO) method, ideal for large quantities of similar items. The drive-in configuration minimizes aisle space, enabling high stacking of pallets while maintaining easy access for retrieval. This system is particularly suitable for warehouses with limited space and high inventory turnover, enhancing overall operational efficiency.

Radio Shuttle Pallet Racking System

A radio shuttle pallet rack is an advanced storage system that utilizes automated shuttles to transport pallets within the rack structure. This system allows for high-density storage while enabling efficient inventory management. The shuttles operate on tracks within the rack, facilitating rapid retrieval and replenishment of pallets without the need for forklifts to navigate narrow aisles. Ideal for facilities with high-volume inventory, shuttle pallet racks enhance productivity, optimize space utilization, and improve overall operational efficiency in warehouse environments.

Double Deep Pallet Racking System

A double-deep pallet rack is a storage system that allows two pallets to be stored back-to-back in a single rack bay, effectively maximizing storage density. This design utilizes a deep aisle configuration, which increases the number of pallets stored while reducing aisle space. Typically accessed by specialized forklifts, double-deep racks are ideal for warehouses with high inventory turnover of similar products. This system enhances operational efficiency and optimizes space utilization, making it a popular choice in modern warehousing solutions.

Very Narrow Aisle Pallet Racking System

A narrow aisle pallet rack is a storage solution designed for high-density warehousing, featuring closely spaced racks that maximize vertical space while minimizing aisle width. This configuration allows for efficient use of warehouse floor space, accommodating more inventory in a smaller area. Typically accessed by narrow-aisle forklifts, this system enhances operational efficiency by enabling quick retrieval and replenishment of pallets. Ideal for facilities with limited space and high storage needs, narrow aisle racks optimize overall warehouse productivity and inventory management.

Automated Storage And Retrieval System

An automated storage and retrieval system (AS/RS) is a high-tech warehouse solution designed to efficiently store and retrieve products with minimal human intervention. Utilizing automated machinery, such as robotic shuttles and conveyor systems, AS/RS maximizes storage density while streamlining inventory management. This system enhances accuracy, reduces labor costs, and improves overall operational efficiency. Ideal for various industries, automated warehouses facilitate quick access to goods, optimize space utilization, and support high-volume throughput in modern supply chain operations.

Mobile Pallet Racking System

A mobile pallet rack system is a flexible storage solution that allows entire rows of racks to be moved along tracks, optimizing space utilization in warehouses. This design creates adjustable aisles as needed, facilitating access to stored pallets while minimizing unused floor space. Ideal for facilities with fluctuating inventory levels, mobile pallet racks enhance operational efficiency by maximizing storage density and allowing for quick retrieval. This system is particularly beneficial in environments requiring adaptability and high-density storage without compromising accessibility.