Structural Steel Mezzanine

What Is Structural Steel Mezzanine

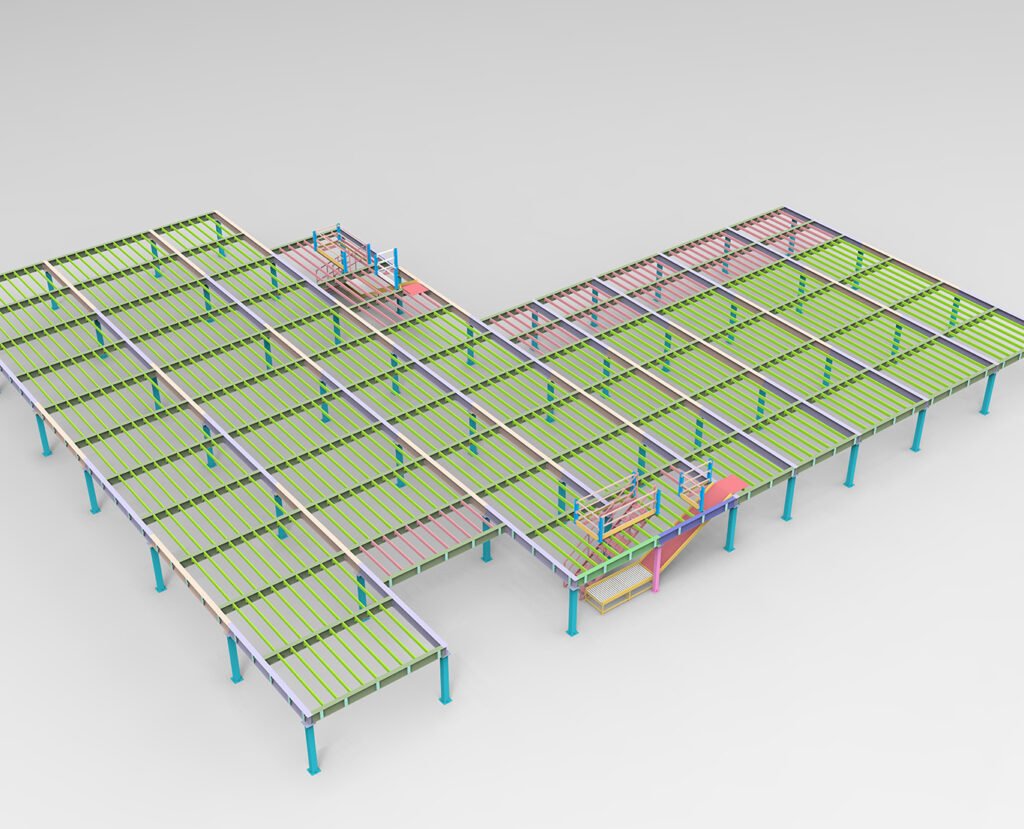

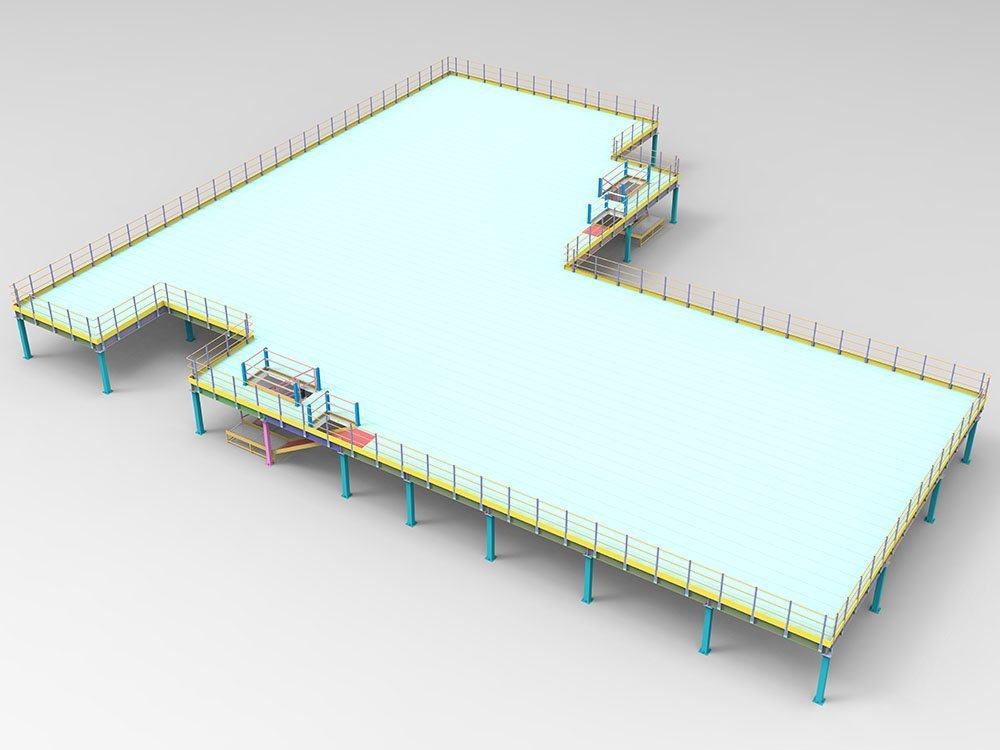

Steel structure mezzanine, also known as work platform, is an important structural form in modern architecture. The steel structure mezzanine is usually composed of pavement, primary and secondary beams, columns, column support and other parts, sometimes including ladders, railings and other auxiliary facilities, between the various parts are fixed by welding seams, screws or rivets and other connection methods, forming a stable full-assembly structure, this structure design is flexible, can be customized according to different site conditions and use needs. To meet a variety of complex process and logistics requirements

When designing and using structure steel mezzanine, the following points need to be noted

Structural design: Reasonable structural design should be carried out according to the use needs and site conditions to ensure that the mezzanine has sufficient carrying capacity and stability.

Material selection: Reliable steel should be selected as the main material of the mezzanine, and anti-corrosion treatment should be carried out as required to improve its durability.

Construction specifications: In the construction process should be strictly in accordance with the relevant standards and specifications to ensure construction quality and safety.

Maintenance: Regular inspection and maintenance of the steel structure mezzanine, timely discovery and treatment of potential problems and hidden dangers, to ensure its long-term stable operation.

Structural Steel Mezzanine Design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

Next, we will design a structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Structure Steel Mezzanine

High strength and light weight: The steel structure material has the characteristics of high strength and light weight, which makes the steel structure mezzanine require less material when bearing the same weight, thereby reducing the weight of the overall structure and facilitating transportation and installation.

Good plasticity and toughness: Steel structure materials can have a certain plastic deformation without damage when subjected to external force, and have good toughness and can withstand greater impact forces to ensure the safety and stability of the mezzanine.

Easy processing and installation: steel structure materials are easy to cut, weld and assemble, which makes the construction period of the steel structure mezzanine shorter and improves the construction efficiency. In addition, the fully assembled structure is also easy to disassemble and reassemble to adapt to different use cases.

Economical and practical: The steel structure mezzanine adopts standardized and modular design, which makes the manufacturing cost and maintenance cost of the mezzanine low. At the same time, its construction period is short, can save a lot of human and material resources.

Versatility: Steel mezzanine can be customized according to different use needs, such as indoor and outdoor mezzanine, mezzanine under static and dynamic loads, production auxiliary mezzanine, and medium and heavy duty operating mezzanine.

Application Of Structure Steel Mezzanine

Steel structure mezzanine is widely used in various fields because of its unique advantages and wide application

Steel structure mezzanine is widely used in various industrial production workshops, warehouses, equipment platforms and other places. Its characteristics of high strength, light weight and easy processing make the steel structure mezzanine able to meet the high requirements for structural stability and construction efficiency in the industrial field.

Shopping malls, supermarkets, exhibition halls and other commercial places also often use steel structure mezzanine. The flexibility and aesthetics of the steel structure mezzanine make it able to adapt to the diversified space needs of commercial places, while its good durability can also meet the needs of long-term operation of commercial places.

Steel structure mezzanine also has a wide range of applications in the field of public facilities, such as sports venues, exhibition centers, public transportation facilities, etc. Its safe and reliable characteristics enable the steel structure mezzanine to provide safe and convenient services to the public.Fresh food area: In the fresh food area, the selective pallet rack can provide good ventilation and hygiene conditions to meet the requirements of food preservation and safety.

The following factors need to be considered when selecting the Structure Steel Mezzanine

Reasonable structural design should be carried out according to the use needs and site conditions to ensure that the mezzanine has sufficient carrying capacity and stability

Reliable steel should be selected as the main material of the mezzanine, and anti-corrosion treatment should be carried out as required to improve its durability

Whether there is a suitable handling equipment (such as forklift, elevator, etc.) and the operation requirements of the equipment.

The cost of steel structure is a complex concept, which is affected by many factors, including material cost, design cost, processing cost, installation cost and other costs

Frequently Asked Questions About Structure Steel Mezzanine

The load-bearing capacity of a steel structure mezzanine mainly depends on its design, steel specifications, connection methods and support structures. In the design phase, we will carry out detailed load calculations according to customer needs and mezzanine uses (such as warehousing, production lines, etc.) to ensure that the mezzanine can safely withstand the predetermined maximum load. The choice of steel is also key, and high-strength steel can provide greater load-bearing capacity. In addition, reasonable connection and strong support structure are also important factors to ensure load-bearing performance.

The service life of steel structure mezzanine is affected by many factors, including material quality, use environment, maintenance status and so on. In general, if high-quality steel is selected, appropriate anti-corrosion measures are taken, and regular maintenance and inspection are carried out during use, the service life of the steel structure mezzanine can be up to decades. Of course, the specific service life needs to be evaluated according to the actual situation.

The anti-corrosion treatment of steel structure mezzanine is an important measure to extend its service life. Common anti-corrosion methods include hot dip galvanizing, spraying anti-corrosion coatings and so on. Hot dip galvanizing is to immerse steel structural parts in molten zinc liquid to form a uniform zinc-iron alloy layer, which has excellent anti-corrosion properties. The spraying anti-corrosion coating is to coat one or more layers of anti-corrosion coating on the surface of the steel structure to isolate air and moisture and achieve the purpose of anti-corrosion. The specific choice of anticorrosion method needs to be determined according to the use environment and requirements of the mezzanine.

The installation period of a steel structure mezzanine varies depending on the size, complexity and site conditions of the mezzanine. In general, small, simple mezzanines can be installed in a few days; Large, complex mezzanines can take weeks or even months. During the installation process, we will formulate a reasonable construction plan according to the actual situation of the site to ensure that the installation work is efficient and orderly.

The safety of steel mezzanine is the primary consideration. We will take a series of measures to ensure their safety during the whole process of design, manufacturing, installation and use. Strict load calculation and structural analysis are carried out during design. Material quality and processing accuracy are strictly controlled in the manufacturing process; The installation will be carried out in accordance with the requirements of the code, and strict quality inspection; Regular maintenance and inspection will be carried out during use to discover and deal with potential safety hazards in a timely manner.

The steel structure mezzanine has good adaptability and flexibility, and can be customized according to different terrain and height requirements. In the design stage, we will fully consider the site topography, geomorphology and customer needs to design a mezzanine structure and support mode that meets the requirements. For highly demanding mezzanines, we can adopt measures such as multi-layer structural design or the addition of support columns to meet the demand.

Compared to other types of mezzanines, the maintenance cost of steel structure mezzanines is relatively low. Because steel has good durability and corrosion resistance, it is not easy to be eroded by the natural environment. At the same time, the structure of the steel structure mezzanine is simple and clear, which is easy to carry out daily maintenance and inspection. Of course, in order to maintain the good condition of the mezzanine and extend its service life, we still recommend that customers carry out regular maintenance and maintenance work.

When choosing the right steel structure mezzanine supplier, it can be considered from the following aspects: First, the strength and credibility of the supplier, which can be evaluated by viewing its qualification certificate, performance cases, etc.; Second, the quality and performance of the product, you can ask the supplier to provide samples or field visits; Third, the level of after-sales service, to understand the supplier’s pre-sale, sale and after-sales service content and commitment; The fourth is the price factor, but it is not recommended to simply choose the price as the only standard, but should consider the cost performance comprehensively.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!