Select Pallet Racking System

What Is Selective Pallet Racking System

Selective pallet racking is an efficient and flexible warehousing solution designed for optimized cargo access and management. It allows warehouse operators to directly access and handle pallets stored in any location without moving adjacent pallets or goods, greatly improving storage efficiency and cargo handling speed.

Customizable Selective Pallet Racking System

We have prepared for you some common selective pallet racking sizes, such as those suitable for W1200*D1000 pallets, as well as W1100*D1100 pallets, and W1200*D800 pallets.

| Rack Size(mm) | Color | Layer | Load Capacity |

|---|---|---|---|

| L2700*D800*H4500 | Orange+Blue | 2-5 levels | 500-4000KG |

| L2500*D900*H4500 | Orange+Blue | 2-5 levels | 500-4000KG |

| L2700*D600*H4500 | Orange+Blue | 2-5 levels | 500-4000KG |

| Customizable | Orange+Blue | 2-5 levels | 500-4000KG |

Selective Pallet Racking System Design

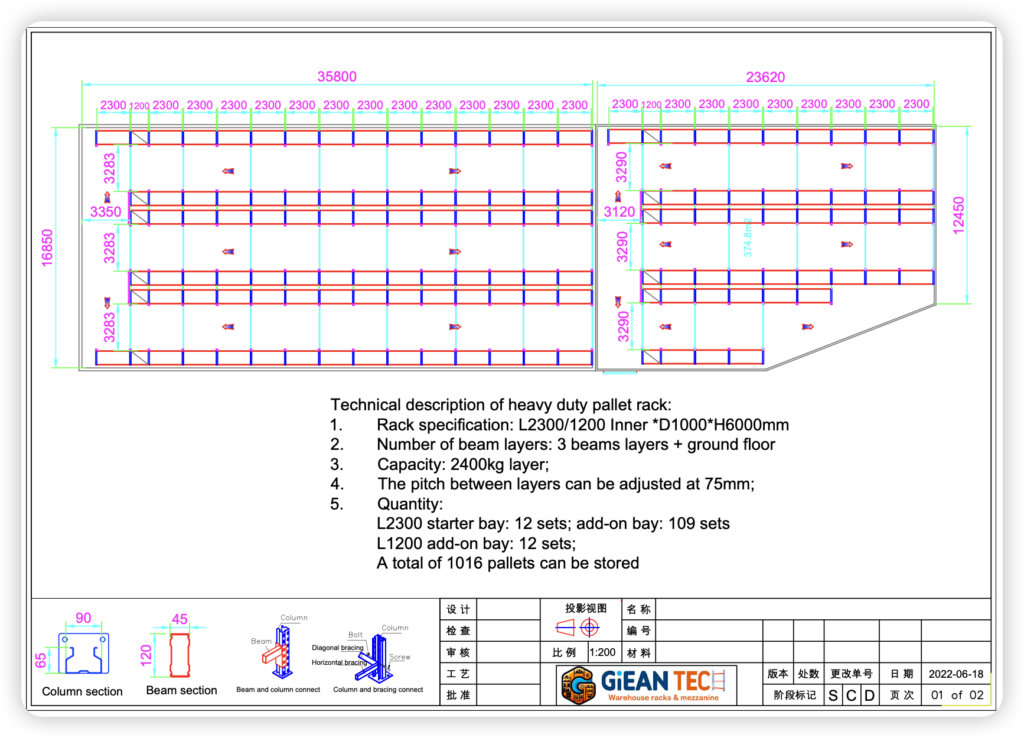

Warehouse Layout Design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

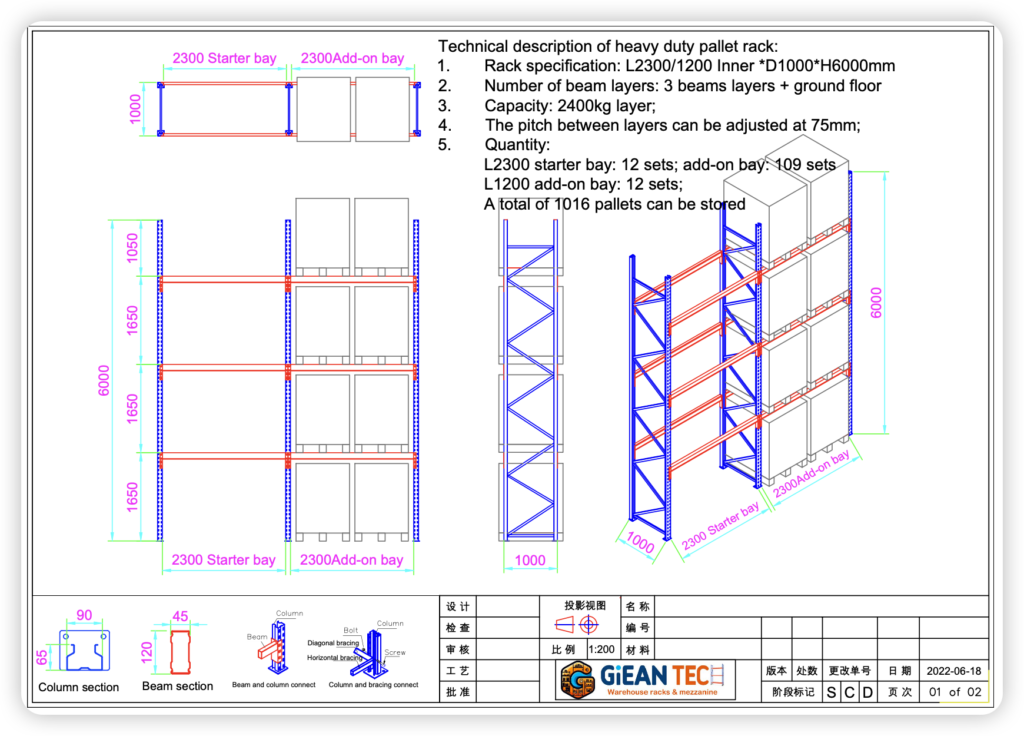

Racking Structure Design

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

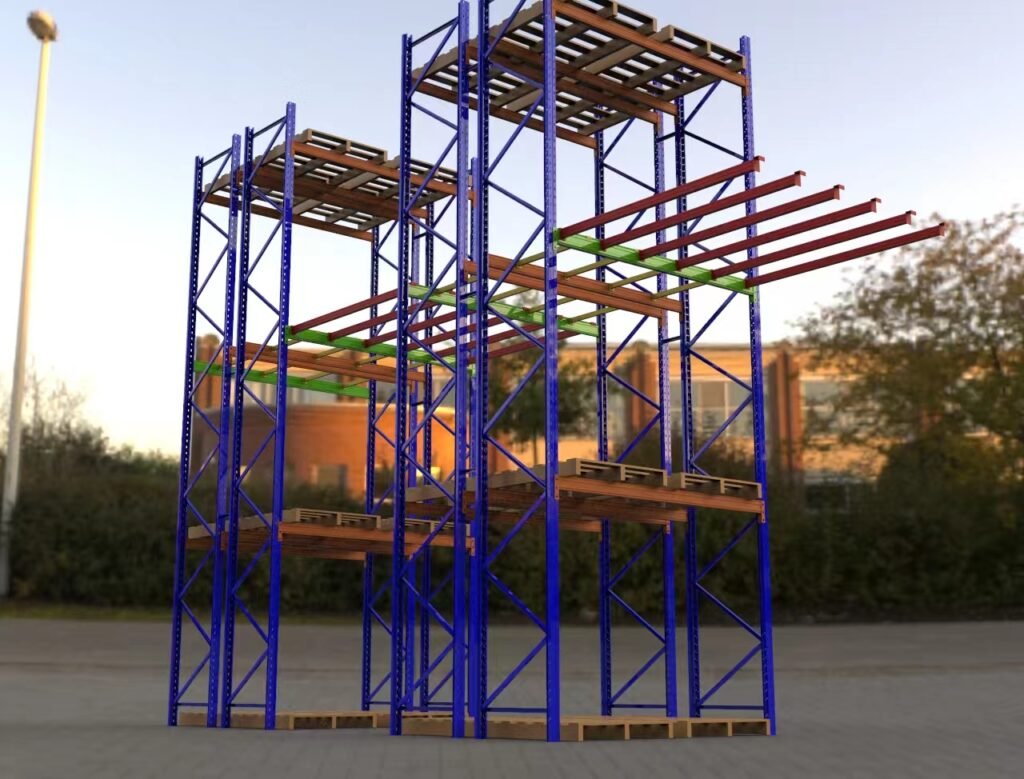

3D rendering design

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Selective Pallet Racking System

1.High flexibility: Selective pallet racking systems are flexible in structure and can be customized according to the specific dimensions, cargo types and storage needs of the warehouse. The settings of different floor heights can accommodate different sizes of pallets and packages, maximizing the use of space.

2.Convenient access: Each layer of pallets can be accessed independently. Using equipment such as forklifts, stackers or electric lifting platforms, operators can easily reach and remove or store pallets at any location, reducing search and waiting time.

3.Large storage capacity: Although the system emphasizes selectivity, the system can still provide large storage capacity while maintaining efficient access. By increasing the height and depth of racks, the warehouse’s cargo storage capacity can be significantly increased.

4.Easy to manage: Since the location of each pallet is traceable, the warehouse management system (WMS) can be easily integrated into the selective pallet racking system to achieve real-time monitoring and accurate management of inventory.

5.Cost-effectiveness: Compared to automated storage systems, selective pallet racking systems require lower initial investment and moderate maintenance costs. This is a cost-effective and efficient storage solution for most small and medium-sized businesses.

Application Of Selective Pallet Racking System

Warehousing and logistics industry

Large-scale warehousing: In large logistics centers, distribution centers or third-party warehouses, selective pallet racks are widely used because of their strong load-bearing capacity and high space utilization. They can store goods ranging from fast moving consumer goods to heavy machinery and equipment, and can be customized to meet different storage needs.

Automated warehouse: With the development of logistics automation technology, many warehouses began to use automated three-dimensional warehouse system (AS/RS), selective pallet rack as an important part of it, with automated handling equipment (such as stackers, forklifts, pallet transport robots, etc.) to achieve efficient and accurate cargo access.

Manufacturing industry

Storage of raw materials and finished products: In the manufacturing industry, storage of raw materials, semi-finished products and finished products is an important part of production management. The selective pallet rack can be flexibly configured according to the size, weight and access frequency of different materials, improving storage efficiency and reducing logistics costs.

Temporary storage area next to the production line: a selective pallet rack is set up next to the production line as a temporary storage area, which can facilitate workers to quickly access materials, reduce waiting time and handling distance, and improve production efficiency.

Supermarkets and shopping malls

Product display and storage: Supermarkets and shopping malls use selective pallet racks for display and storage of various products. Through reasonable layout and design, it not only improves the space utilization rate, but also enhances the shopping experience of customers.

Fresh food area: In the fresh food area, the selective pallet rack can provide good ventilation and hygiene conditions to meet the requirements of food preservation and safety.

The following factors need to be considered when selecting the appropriate selective pallet rack

Warehouse conditions

Include the ground bearing capacity, space size, and height restrictions of the warehouse.

Cargo characteristics

The size, weight, frequency of access and whether special storage conditions (such as temperature and humidity control) are required.

Equipment

Whether there is a suitable handling equipment (such as forklift, stacker, etc.) and the operation requirements of the equipment.

Cost budget

Select cost-effective pallet rack type and configuration according to the budget.

Frequently Asked Questions About Selective Pallet Racking System

First of all, it is very important to determine the maximum weight of your storage items. Different selective pallet racking systems have different load-bearing capacity designs, ranging from light to heavy duty. Make sure the system you choose can withstand the maximum weight of the items you plan to store to ensure safety and long-term stability.

Knowing the size, height, and available space layout of your warehouse or storage area is key to choosing the right selective pallet racking system. Consider the height, depth, width and row spacing of the shelves to ensure maximum use of space and easy access to goods.

Selective pallet racking systems should facilitate quick access to goods. Ask if the shelf design supports the operation of forklifts, stackers, or other automation equipment, and the aisle width requirements for these devices. In addition, consider whether you need to configure a guide system (such as rack labels, indicators, etc.) to improve picking efficiency.

Knowing how the rack system is installed, how long it takes and whether a professional team is required to install it. At the same time, consider whether the daily maintenance, inspection and adjustment of the shelf is easy, and whether there are easy to replace parts.

Budget is an important factor in the buying process. Consider not only the initial purchase cost of the selective pallet racking system, but also its long-term operating costs, including maintenance costs, possible upgrades or expansion costs, etc. Compare prices and services from different suppliers to find the most cost-effective solution.

Ensure that the selected pallet racking system complies with local safety standards and industry specifications. Ask the supplier about product certification, safety features (such as anti-tilt devices, crash protection, etc.) and whether safety training or guidance is provided. In addition, taking into account the need for emergency evacuation and fire access, ensure that the shelf layout does not obstruct these critical paths.