Roll Container

What Is Roll Container

A roll container, also known as a cargo truck, cage truck, or turnover truck, is a unit mobile container equipped with four casters to transport and store materials.

The roll container has a large carrying capacity and stability, can quickly transport goods, significantly improve the handling efficiency; It can replace manual handling of goods, effectively reduce the labor burden and reduce labor costs.

Features of Roll container

Simple structure: The roll container is usually composed of a platform and four wheels (including two directional wheels and two universal wheels), which is simple in structure and easy to operate and maintain.

Strong load capacity: the roll container can carry different weights and volumes of items, the general load capacity is between 100 kg and 1000 kg, suitable for a variety of logistics transportation and storage occasions.

Low cost: Compared with other logistics transportation and storage vehicles, roll containers are lower in cost, easy to purchase and maintain, while also improving work efficiency and reducing labor costs.

High safety: roll container are usually made of high-quality materials, strong and durable, and some are also equipped with safety devices such as non-slip pads and safety handrails to ensure the safety of goods and staff.

Strong versatility: roll container can be used for logistics transportation and warehousing in different industries, such as factories, stores, warehouses, etc., and can also be customized according to different needs, such as adding handrails, folding design, etc.

Flexible movement: The wheel design enables it to rotate and move in a small space, and can adapt to different ground conditions, which is convenient for manual implementation.

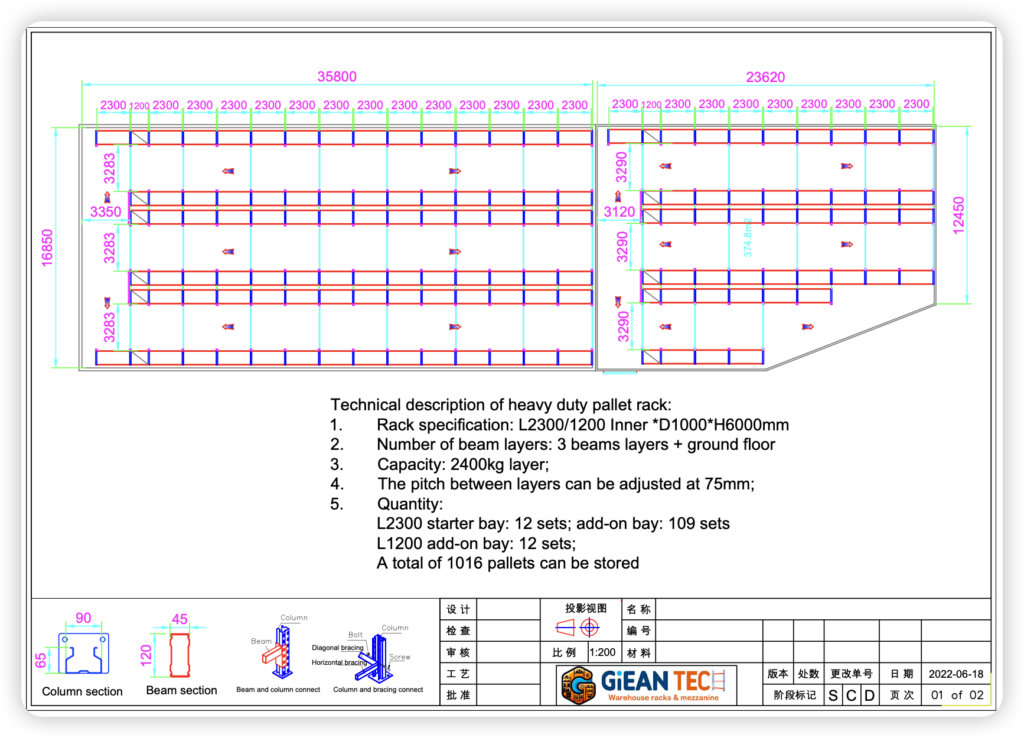

The process of Giean warehouse roll container layout drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

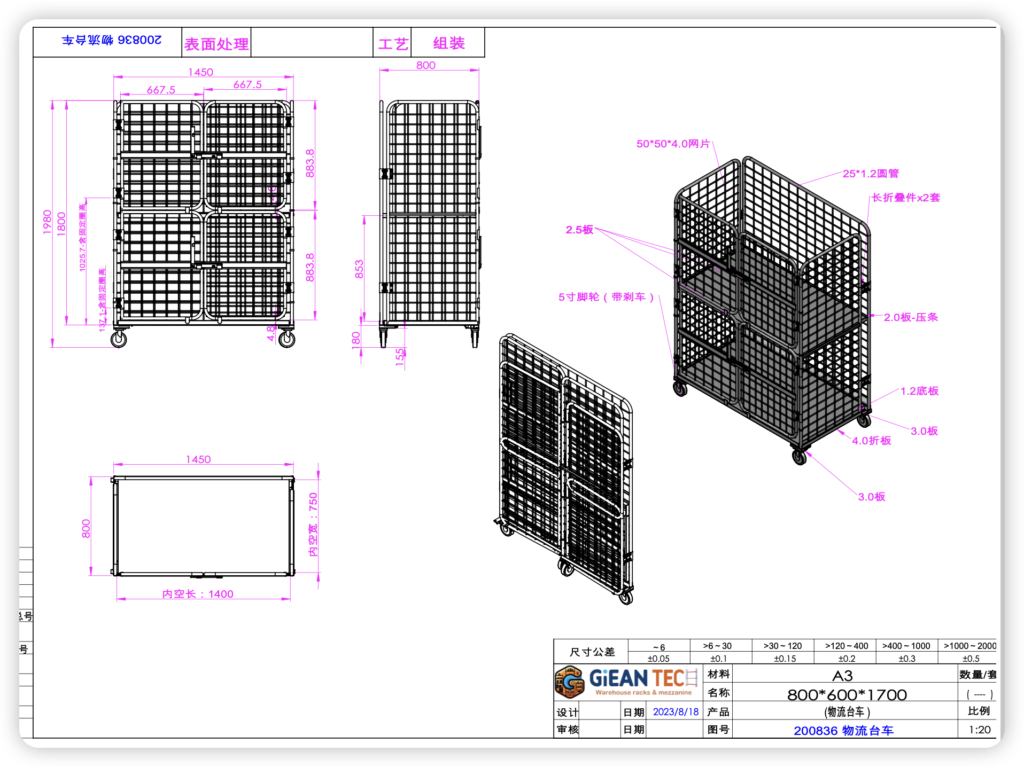

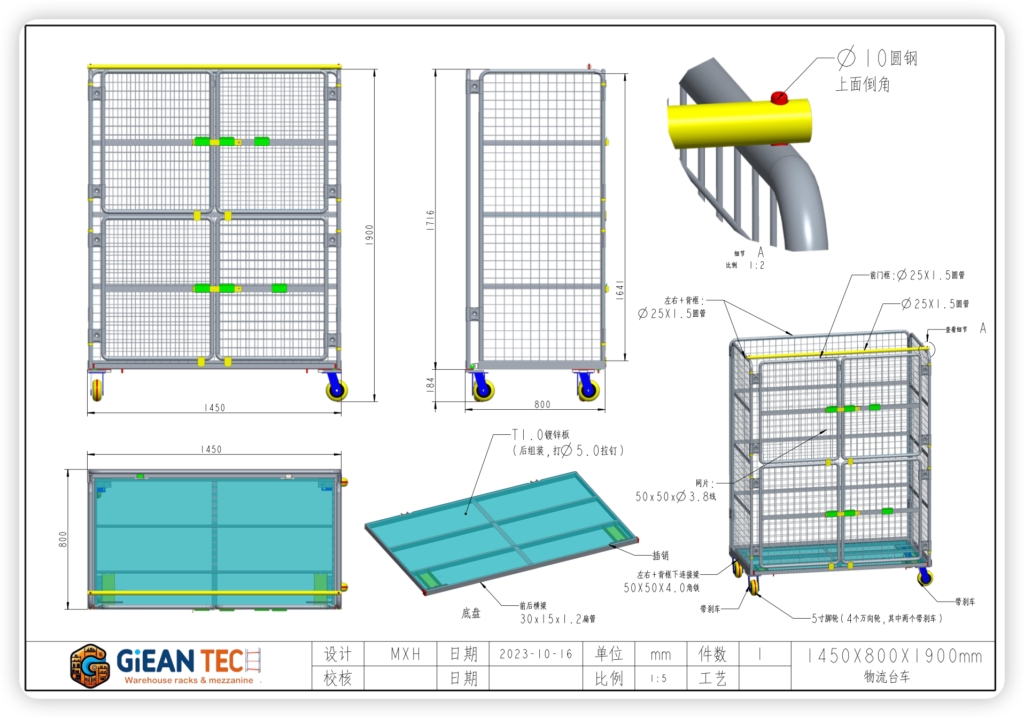

Next, we will design a roll container structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Roll Container

Quality materials: We use high strength, corrosion resistant quality materials to manufacture roll container to ensure product durability and stability.

Strict testing: We carry out strict quality testing on each batch of roll container to ensure that they meet relevant standards and customer requirements.

Diversified choice: We provide a variety of roll container, such as fixed, folding, detachable, etc., to meet the needs of different customers.

Customized services: We can provide tailor-made logistics trolley solutions according to the specific needs of customers, including size, load bearing, caster configuration, etc.

Long-term guarantee: We promise to provide long-term quality assurance and maintenance services for the roll container sold to reduce customers’ worries.

Integrity management: We adhere to the principle of integrity management, focusing on long-term cooperation and win-win development with customers.

Continuous improvement: We are committed to continuous improvement and innovation, and constantly improve product quality and service level to meet the changing needs of customers.

Common styles and sizes of roll container

| Size(mm) | Container Door | Layer | Load Capacity |

|---|---|---|---|

| L1100*D800*H1700 | No | 1 levels | 500KG |

| Customizable | Customizable | 1-4 levels | 0-1000KG |

| Size(mm) | Container Door | Layer | Load Capacity |

|---|---|---|---|

| L1100*D800*H1700 | No | 2 levels | 500KG |

| Customizable | Customizable | 1-4 levels | 0-1000KG |

| Size(mm) | Container Door | Layer | Load Capacity |

|---|---|---|---|

| L1100*D800*H1700 | Yes | 1 levels | 500KG |

| Customizable | Customizable | 1-4 levels | 0-1000KG |

| Size(mm) | Container Door | Layer | Load Capacity |

|---|---|---|---|

| L1100*D800*H1700 | Yes | 3 levels | 500KG |

| Customizable | Customizable | 1-4 levels | 0-1000KG |

Frequently Asked Questions About Selective Pallet Racking System

Roll containers are versatile storage and transportation solutions primarily used in industries such as manufacturing, logistics, and warehousing. They facilitate the movement of goods by allowing easy rolling from one location to another, enhancing efficiency and reducing manual handling.

Roll containers are typically constructed from durable materials like steel, aluminum, or heavy-duty plastic. These materials ensure that the containers can withstand the rigors of daily use while maintaining lightweight portability.

Yes, many roll containers are designed to be stackable, allowing for space-efficient storage when not in use. Stackable features often include interlocking mechanisms to prevent shifting or collapsing.

Roll containers come in a variety of sizes to accommodate different types of loads and storage needs. Common sizes range from small, compact models suitable for lightweight parts to large, heavy-duty containers capable of holding several hundred pounds. Standard dimensions typically include lengths from 24″ to 48″ and widths from 24″ to 36″, but custom sizes are also available.

Yes, roll containers are equipped with wheels, usually located at the base. These wheels can be either fixed or swivel casters, providing maneuverability and ease of movement across floors, including those with slight inclines or uneven surfaces.

While some roll containers are designed for indoor use, others are weather-resistant and suitable for outdoor applications. Outdoor models often feature rust-proof materials and heavy-duty wheels to withstand rain, snow, and other environmental factors.

Absolutely! Roll containers can be customized to meet specific needs, including custom sizes, colors, materials, and additional features like dividers, labels, or integrated locking mechanisms. Manufacturers often offer a range of customization options to fit unique requirements.

Regular maintenance of roll containers involves inspecting wheels for wear and tear, cleaning the containers to prevent rust or corrosion, and ensuring that any moving parts (like latches or interlocks) are functioning smoothly. Storing them in a dry, protected environment when not in use can also extend their lifespan. Additionally, following the manufacturer’s guidelines for load capacity and proper handling practices will help maintain the structural integrity of the containers.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!