Pallet Racking System

Pallet Racking System Definition

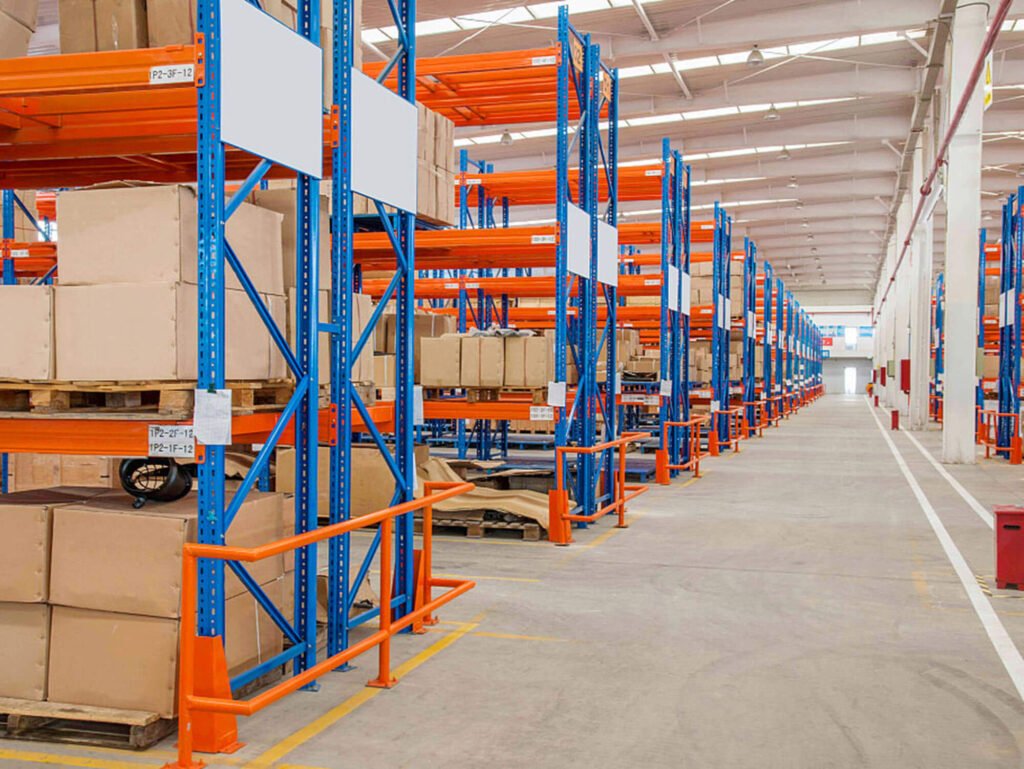

A pallet rack system is a structure designed for storing and managing goods, primarily intended to support standardized pallets. This system allows for the stacking of goods on pallets and utilizes a rack framework to provide efficient access, making it widely used in warehousing and logistics.

Key Features:

High-Density Storage: Pallet rack systems maximize vertical space in warehouses, increasing storage density.

Flexibility: The layout can be adjusted to accommodate various storage needs, adapting to different types and sizes of pallets.

Quick Access: Designed to allow forklifts and other equipment to easily enter the racks, facilitating rapid retrieval of goods and enhancing operational efficiency.

Safety: Pallet rack systems are often equipped with anti-tilt and stabilization measures to ensure the safe storage of goods.

Types Of Pallet Racking Systems

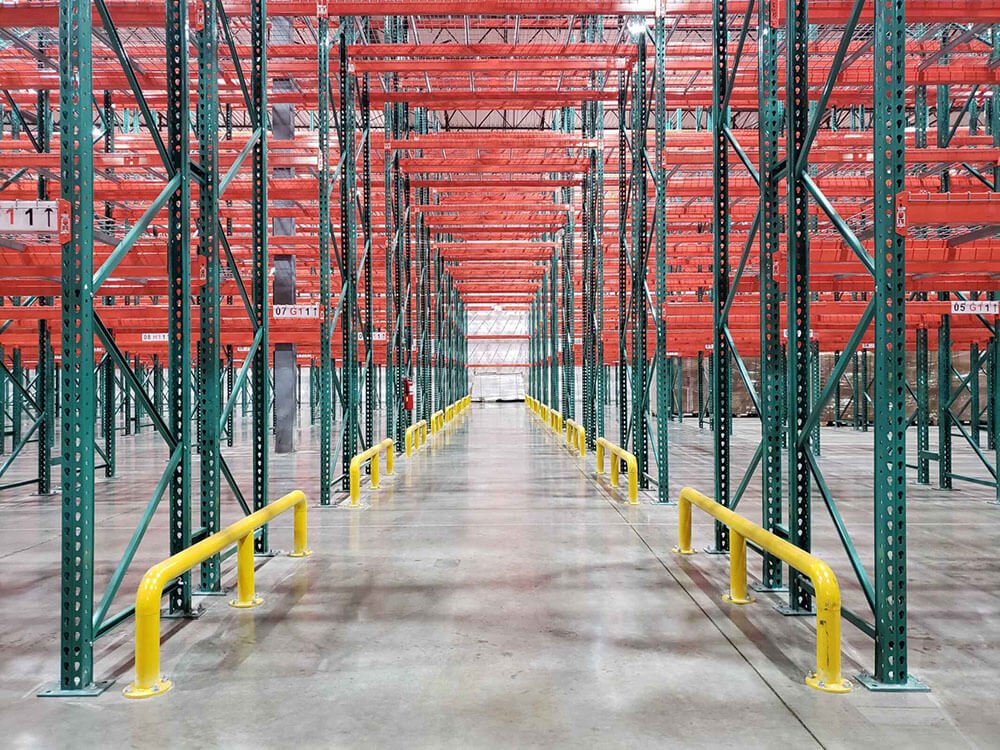

Selective Pallet Racking System

A selective pallet rack is a versatile storage system designed to provide easy access to individual pallets. This system allows for a wide range of pallet sizes and weights, enabling efficient inventory management. Each pallet is directly accessible without needing to move others, making it ideal for facilities with diverse product lines. Selective pallet racks optimize space utilization while facilitating quick retrieval and replenishment, enhancing overall warehouse efficiency and productivity.

Teardrop Pallet Racking System

A teardrop pallet rack is a popular storage solution characterized by its distinctive tear-drop shaped holes, allowing for easy assembly and adjustment of beams. This system provides high-density storage while ensuring direct access to pallets. Its design accommodates various pallet sizes and weights, making it versatile for different warehouse needs. The tear drop configuration enhances stability and safety, facilitating efficient inventory management and quick retrieval, ultimately optimizing warehouse operations and space utilization.

Drive In Drive Through Pallet Racking System

A drive-in pallet rack is a space-efficient storage system that allows forklifts to enter the rack structure for direct access to pallets. This design maximizes storage density by using a last-in, first-out (LIFO) method, ideal for large quantities of similar items. The drive-in configuration minimizes aisle space, enabling high stacking of pallets while maintaining easy access for retrieval. This system is particularly suitable for warehouses with limited space and high inventory turnover, enhancing overall operational efficiency.

Radio Shuttle Pallet Racking System

A radio shuttle pallet rack is an advanced storage system that utilizes automated shuttles to transport pallets within the rack structure. This system allows for high-density storage while enabling efficient inventory management. The shuttles operate on tracks within the rack, facilitating rapid retrieval and replenishment of pallets without the need for forklifts to navigate narrow aisles. Ideal for facilities with high-volume inventory, shuttle pallet racks enhance productivity, optimize space utilization, and improve overall operational efficiency in warehouse environments.

Double Deep Pallet Racking System

A double-deep pallet rack is a storage system that allows two pallets to be stored back-to-back in a single rack bay, effectively maximizing storage density. This design utilizes a deep aisle configuration, which increases the number of pallets stored while reducing aisle space. Typically accessed by specialized forklifts, double-deep racks are ideal for warehouses with high inventory turnover of similar products. This system enhances operational efficiency and optimizes space utilization, making it a popular choice in modern warehousing solutions.

Very Narrow Aisle Pallet Racking System

A narrow aisle pallet rack is a storage solution designed for high-density warehousing, featuring closely spaced racks that maximize vertical space while minimizing aisle width. This configuration allows for efficient use of warehouse floor space, accommodating more inventory in a smaller area. Typically accessed by narrow-aisle forklifts, this system enhances operational efficiency by enabling quick retrieval and replenishment of pallets. Ideal for facilities with limited space and high storage needs, narrow aisle racks optimize overall warehouse productivity and inventory management.

Automated Storage And Retrieval System

An automated storage and retrieval system (AS/RS) is a high-tech warehouse solution designed to efficiently store and retrieve products with minimal human intervention. Utilizing automated machinery, such as robotic shuttles and conveyor systems, AS/RS maximizes storage density while streamlining inventory management. This system enhances accuracy, reduces labor costs, and improves overall operational efficiency. Ideal for various industries, automated warehouses facilitate quick access to goods, optimize space utilization, and support high-volume throughput in modern supply chain operations.

Mobile Pallet Racking System

A mobile pallet rack system is a flexible storage solution that allows entire rows of racks to be moved along tracks, optimizing space utilization in warehouses. This design creates adjustable aisles as needed, facilitating access to stored pallets while minimizing unused floor space. Ideal for facilities with fluctuating inventory levels, mobile pallet racks enhance operational efficiency by maximizing storage density and allowing for quick retrieval. This system is particularly beneficial in environments requiring adaptability and high-density storage without compromising accessibility.

Factors To Consider When Choosing A Pallet Racking System

To ensure that the racking system will meet specific storage needs. The following are key factors to consider when selecting a pallet racking system:

1. Load Capacity: Ensure the rack can support the weight of the pallets and products being stored.

2. Pallet Size: Determine the dimensions of the pallets to ensure compatibility with the rack design.

3. Warehouse Layout: Assess the available space and plan for optimal rack configuration and aisle width.

4. Accessibility: Evaluate how easily pallets can be retrieved and stored, considering the type of forklift used.

5. Inventory Turnover: Consider the frequency of pallet movement to choose a system that accommodates your inventory flow.

6. Safety Features: Look for racks with safety measures, such as anti-tip mechanisms and sturdy construction.

7. Flexibility: Select a system that allows for easy reconfiguration as storage needs change.

8. Material Type: Choose between steel, aluminum, or other materials based on durability and cost.

9. Cost: Factor in initial investment, installation, and long-term maintenance costs.

10. Compliance: Ensure the rack meets industry standards and regulations for safety and structural integrity.