Mold Racking System

What Is Mold Racking System

Mold rack, also known as mould rack, mold storage rack or mold finishing rack, is a storage rack designed for storing all kinds of molds and mold accessories. It is mainly used for placing plastic molds, metal molds, stamping molds and other molds, as well as related mold accessories, in order to facilitate the safe and orderly maintenance and management of the molds.

Common Mold Storage Issues for Mold Manufacturers

I. Challenges in Mold Storage and Management

- Molds are bulky and heavy, making storage difficult.

- Standard shelving lacks sufficient load capacity, prone to deformation or creating safety hazards.

- Molds require forklift handling, demanding ample operational space.

- Molds are stored haphazardly, complicating classification and management.

- Molds from different product lines and clients are mixed together.

- Locating and retrieving molds is time-consuming, impacting production efficiency.

- Poor mold identification hinders traceability

- Lack of unified numbering and location systems.

- Molds become difficult to locate after management turnover.

- Low space utilization

- Molds are often stored on the floor or in corners, occupying significant factory floor space.

- Vertical space is severely underutilized.

II. Mold Maintenance and Care Challenges

- Poor storage environments lead to rust or damage

- Storage areas suffer from high humidity, poor ventilation, and excessive dust.

- Lack of regular oiling or protective measures shortens mold lifespan.

- Unsystematic Maintenance Records

- No fixed maintenance cycles.

- Disorganized tracking of mold borrowing, return, and repair information.

- Collision and Damage During Handling

- Limited space and operational difficulties when using cranes or forklifts.

- Absence of safety limit switches and guide rail systems for protection.

III. Production Management and Scheduling Pain Points

- Delayed mold scheduling disrupts production plans

- Extended mold search times cause machine downtime

- Lack of information sharing between shifts

- Mold idling or redundant production

- Poor management leads to “missing mold” situations requiring re-molding, wasting costs

IV. Cost and Safety Challenges

- High costs from mold loss or damage

- Molds carry significant value (typically hundreds of thousands to millions), making damage extremely costly.

- High labor costs

- Reliance on manual handling, retrieval, and registration leads to low efficiency and frequent errors.

- High safety risks

- Heavy molds pose serious injury hazards if improperly stored or handled.

V. Modernization Upgrade Challenges

- Lack of Intelligent, Systemized Management Tools

- Absence of mold management systems (e.g., barcode/RFID tracking).

- Difficulty achieving “visualized warehousing.”

- Stringent Customer Audits and Quality System Requirements

- Major end-customers demand clear mold management and maintenance records.

- A tidy, secure, and organized mold warehouse reflects corporate professionalism.

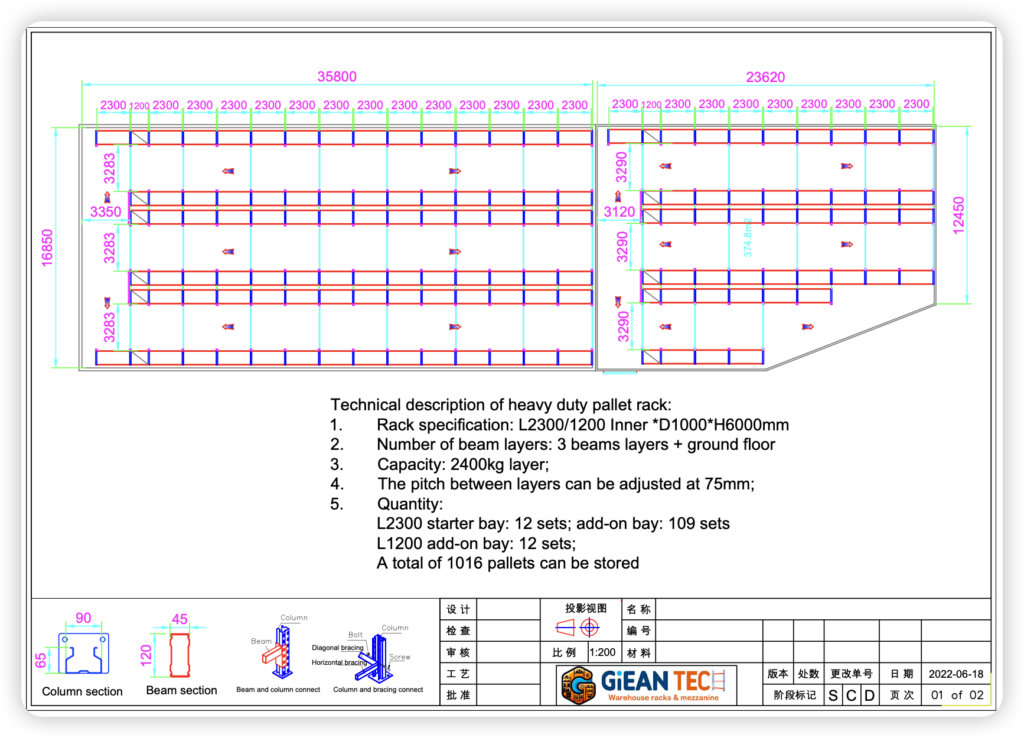

The Process Of Giean Warehouse Storage Solution Drawing Design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

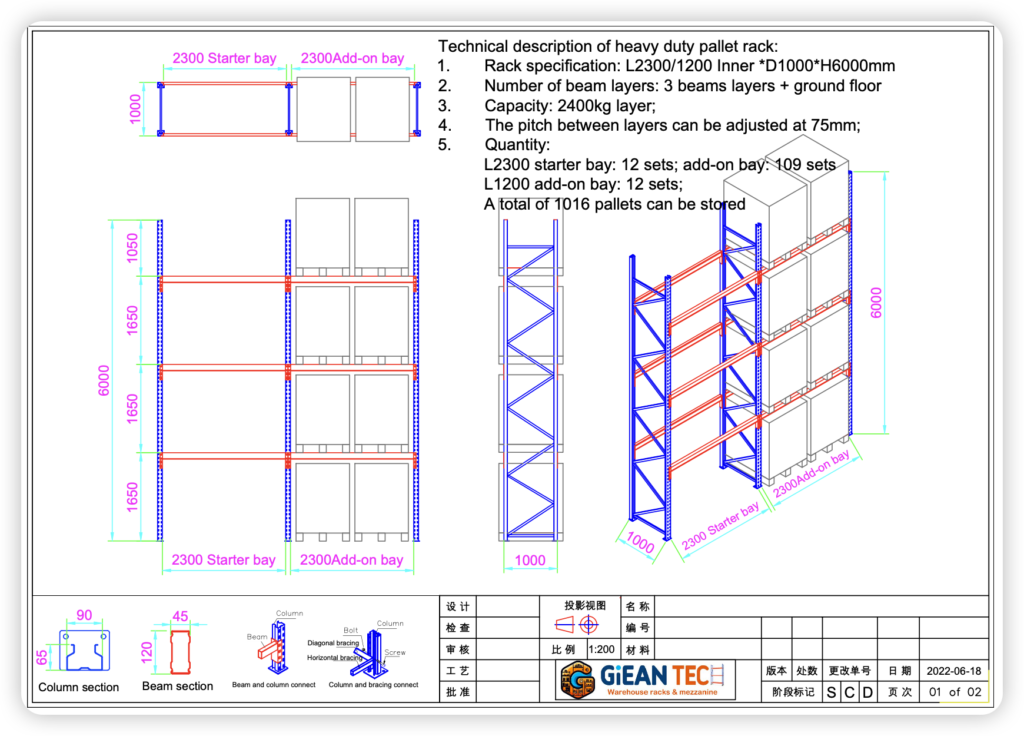

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

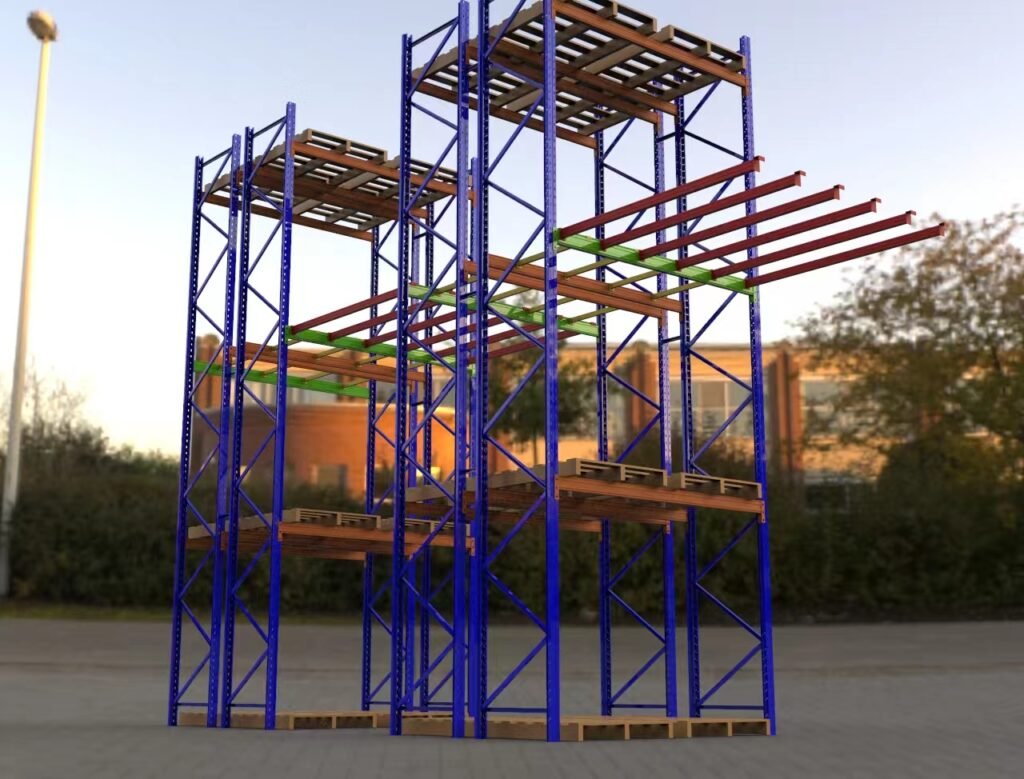

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Mold Racking System

First, high safety performance

Additional positioning device: The mold rack is often equipped with positioning devices, such as positioning pins and limit pins, to ensure the safety of the extraction plate during extraction, to avoid accidental drop, and to use more safe and reliable.

Additional safety devices: Many mold rack are also attached with safety devices, further improving the safety during use.

Second, easy to operate

Smooth sliding: The mold rack adopts bearing combination, smooth sliding, easy to access the mold.

Independent lifting device: Some mold rack are attached with independent lifting device, making mold access easier and faster.

Adjustable footing: The adjustable footing design can overcome the problem of uneven surface of the site and ensure the stability of the mold rack.

Third, Save space

Small footprint: The mold rack covers a small area, usually an area of only about 1.8 square meters, but can store dozens of sets of small and medium-sized molds, effectively saving storage space.

Multi-layer design: Drawer type or layer plate design, so that the mold can be stacked vertically, further saving horizontal space.

Fourth, strong load-bearing capacity

High load-bearing capacity: The load-bearing capacity of the mold rack is strong, and the load-bearing capacity of each cell or each layer can reach 800-3000KG, or even higher, according to different models and specifications.

Reasonable structure: The structural design of the mold rack is scientific and reasonable, and the bearing surface is made of reinforced materials, such as pattern plates, to increase friction and prevent the mold from slipping.

Fifth, Easy to manage and maintain

Classified storage: The mold rack can be classified and stored according to the size and type of the mold, which is easy to manage and find.

Simple structure: The mold rack is assembled by a variety of combination parts, simple structure, easy to disassemble, transport and assembly.

Application Of Mold Racking System

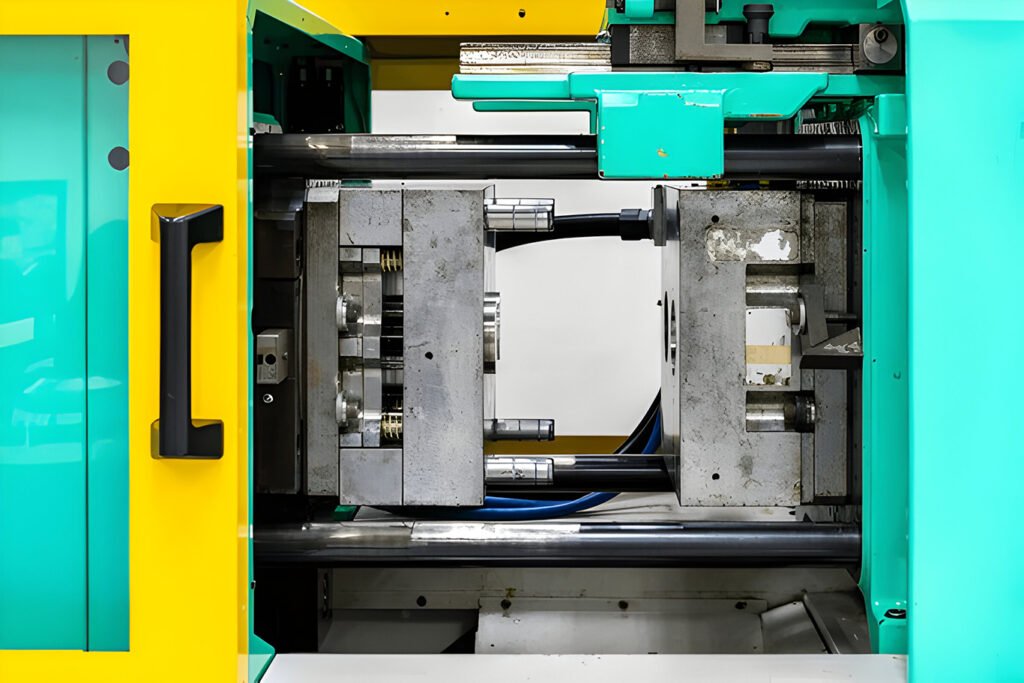

In the production line of plastic products, the mold rack plays a crucial role. It can easily store and manage various plastic molds to ensure the rapid access and return of molds on the production line, so as to ensure the smooth progress of the production process. The design of the mold rack makes the storage of the mold more orderly, reduces the damage and loss of the mold, and improves the production efficiency and product quality.

For the production process of hardware products, the heavy mold rack is an indispensable storage device. These mold racks can stably store large and heavy molds to ensure the safety of molds during storage and use. In the hardware mold manufacturing industry, the use of the mold rack not only improves the safety of production, but also ensures the accuracy and durability of the mold, thus improving the overall quality of the product.

The automobile manufacturing industry is an industry highly dependent on molds. In the production process of automobiles, a large number of molds need to be used to manufacture bodies, parts and so on. The application of mold racks allows automobile manufacturers to efficiently manage and store these molds, ensuring the smooth operation of the production line. At the same time, the mold rack also helps to reduce the damage and loss of the mold, reducing the production cost.

The production of electronic products often involves the use of precision molds, and the storage and management of these molds is crucial to the quality and production efficiency of the products. The mold rack can provide a stable and orderly storage environment to ensure the accuracy and durability of the mold, so as to meet the needs of the electronics manufacturing industry for high-precision and high-efficiency production.

Frequently Asked Questions About Mold Racking System

The load-bearing capacity of a mold racking system depends on its design, material and structural strength. Generally speaking, the high-quality mold rack system can meet the mold storage needs of various heavy weights, including heavy molds. In the selection, should be based on the specific weight and distribution of the mold selection, and consult the supplier to obtain the exact bearing capacity information.

The stability of the mold racking system can be ensured by a variety of measures, such as the use of high-strength materials, stable installation, the addition of support structures and fixtures. In addition, the ground treatment is also key to ensure that the ground is smooth and solid, if necessary, you can set a concrete foundation or install anchor bolts. In the process of use, the mold rack should be regularly checked and maintained to ensure that it is in good condition.

The mold racking system promotes fast access to the mold through optimized design. For example, the use of adjustable panel and drawers to accommodate different sizes and weights of molds; Set up a clear classification identification and numbering system, so that employees can quickly find the required molds; As well as provide convenient movement and locking mechanism, reduce operation time.

The mold rack system ensures the safety of the mold through a variety of measures. First of all, the use of high-strength materials and stable structural design to prevent mold damage due to improper storage. Secondly, safety devices such as locks and guardrails are equipped to prevent unauthorized personnel from touching the mold. In addition, a monitoring and alarm system can also be introduced to monitor the mold storage area in real time to detect and deal with abnormal situations in a timely manner.

Modern mold rack systems often support inventory management and tracking functions. Through integrated inventory management software or interface, the system can update the quantity, location, status and other information of the mold in real time, and support automatic identification technology such as bar code and RFID for rapid inventory and tracking. At the same time, these systems usually provide an integrated interface with the ERP system to achieve seamless docking and sharing of inventory information through data exchange.

The maintenance costs of mold rack systems vary depending on the brand, quality and use environment. In general, high-quality mold rack systems have higher durability and lower maintenance costs. However, in order to ensure the long-term stable operation of the system and extend the service life, regular professional maintenance is recommended. The maintenance includes checking whether the structure is stable, whether the fasteners are loose, whether the coating falls off, etc., and repairing and replacing it as needed.

The mold rack system has a high degree of customization. Most suppliers can customize the design according to the specific needs of customers, including size, load-bearing capacity, structural form, safety devices and so on. The customer can communicate with the supplier about the specific needs, and provide the relevant drawings and parameters for the supplier to customize the design and production.

The installation and relocation of the mold rack system is relatively convenient, but the specific time depends on the system size, complexity and site conditions. In general, the supplier will provide professional installation and relocation services, and will develop a detailed installation and relocation plan according to the actual situation. During the installation, pay attention to safe construction and operate according to the instructions. As for commissioning time, it usually depends on the progress of installation and commissioning and the customer’s familiarity with the system.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!