Mezzanine Floor

What Is mezzanine floor

Mezzanine floor, also known as attic platform, is an intermediate mezzanine built on an existing rack or work site, mainly used to increase storage area and improve space utilization.

Definition: Mezzanine floor is the use of racks as floor support, can be designed into a multi-storey (usually 2-3 floors) structure, while equipped with stairs, guardrail and lifts and other equipment to facilitate the access and transport of goods.

Structure: The whole group of full-type structure of the mezzanine floor adopts special section steel floor, which has strong layer loading capacity, good integrity, uniform floor load and smooth appearance. In the mezzanine floor, light carts or pallet traction carts are generally used.

How to customize the size of the mezzanine floor

The sizing of the mezzanine floor is a comprehensive process that takes into account many factors to ensure that the mezzanine floor meets the needs of use, but also meets the requirements of safety, economy, aesthetics and so on.

Cargo characteristics: First, you need to identify the type of goods that will be stored on the mezzanine floor, their size, weight, and frequency of access. These factors will directly affect the load-bearing capacity, layout and size of the mezzanine floor.

Personnel activities: Consider the space requirements for personnel activities on the mezzanine floor, including operation, maintenance, safe passage, etc.

Equipment requirements: If special equipment needs to be installed on the mezzanine floor (such as racks, conveyor lines, lifts, etc.), the size and layout of these equipment will also have an impact on the size of the mezzanine floor.

Existing space: Measure and evaluate the height, area, load-bearing capacity and other conditions of the existing warehouse or plant to determine the maximum size and number of floors that can be built for the mezzanine floor.

Layout optimization: According to the use needs and space conditions, reasonable planning of the layout of the mezzanine floor, including the aspect ratio, equipment location, etc. Ensure that the mezzanine floor provides sufficient storage space while also facilitating the access of goods and personnel activities.

Load-bearing capacity: According to the use requirements of the mezzanine floor and the characteristics of the goods, select the appropriate material and structural form to ensure that the load-bearing capacity of the mezzanine floor meets the requirements.

Safety standards: Comply with relevant safety standards and specifications, such as mezzanine floor clear height, rail height, baseboard setting, etc., to ensure the safety of people and cargo.

Seismic and fireproof: considering the seismic and fireproof performance of the mezzanine, necessary measures should be taken to improve the safety and stability of the mezzanine.

Cost effectiveness: When customizing mezzanine floor dimensions, consider cost effectiveness. Ensure that the mezzanine floor not only meets the needs of use, but also has a reasonable cost and high cost performance.

Maintenance and management: Consider the maintenance and management costs of the mezzanine floor, and choose structures and materials that are easy to maintain and manage.

Professional consultation: Consult with a professional mezzanine floor manufacturer or design agency for professional advice and solutions.

Design drawing: According to the use requirements and space conditions, draw the detailed design drawing of the mezzanine floor, including size, layout, structure, etc.

Manufacturing and installation: Manufacture and installation according to the design drawings to ensure the quality and safety of the mezzanine floor.

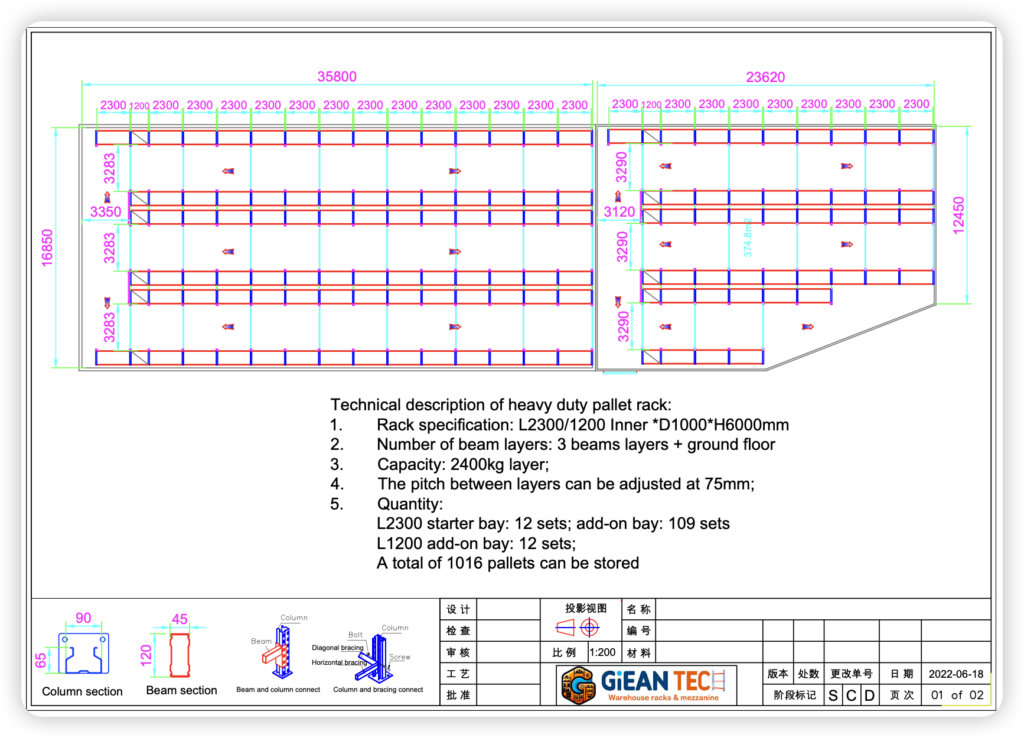

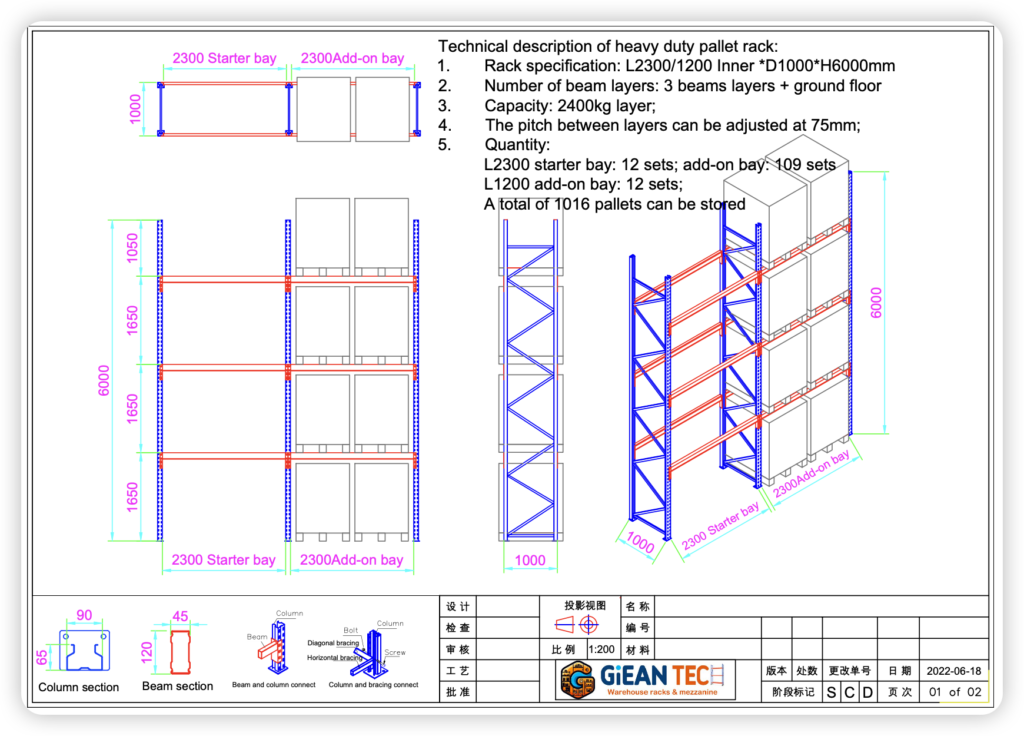

The process of Giean warehouse storage solution drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

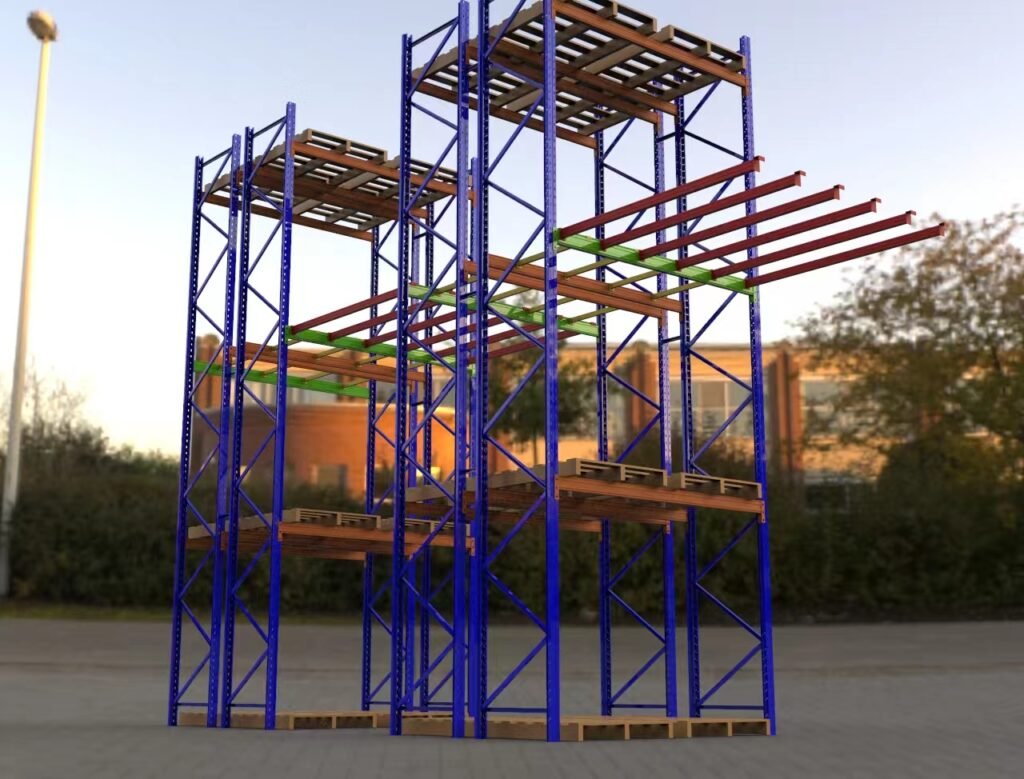

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Mezzanine Floor

1.High space utilization: The mezzanine floor significantly improves space utilization by increasing storage space in the vertical direction of the warehouse. For high-story warehouses, mezzanine floor can transform these otherwise inaccessible Spaces into efficient storage areas.

2.Enhanced storage capacity: Mezzanine floor provide additional storage layers, enabling warehouses to store more goods, especially those that are small, lightweight or require long-term storage. This helps reduce the floor occupancy of the warehouse and leaves more room for other operations.

3.Cost effectiveness: The cost of a mezzanine floor is relatively low compared to expanding a warehouse or leasing new storage space. It is able to utilize the vertical space of existing warehouses without the need to purchase additional land or construct new buildings. In addition, the mezzanine floor can be customized to meet the specific needs of different warehouses.

4.Operating flexibility: Mezzanine floor are usually designed to take into account the access and transportation needs of goods, equipped with stairs, guardrail, lifts and other equipment. This allows operators to easily move goods between different floors, improving the efficiency of warehouse operations.

5.The structure is stable: The mezzanine floor is made of high-strength steel material, which has high load-bearing capacity and structural stability. This ensures the safety and reliability of the mezzanine floor when carrying the cargo, reducing the risk of damage due to the weight of the cargo or improper handling.

6.Strong customization: The mezzanine floor can be customized according to the actual needs and spatial layout of the warehouse. Whether it is the size of the mezzanine floor, the number of layers, the load-bearing capacity or other special needs, it can be adjusted and optimized according to the actual situation to meet the specific needs of different warehouses.

7.Improve the working environment: Through the proper use of vertical space, the mezzanine floor can reduce the clutter and congestion of the warehouse floor. This helps to improve the working environment in the warehouse and increase employee productivity and satisfaction.

8.Environmental Protection and Sustainability: The mezzanine floor was designed and built with an emphasis on environmental protection and sustainability. The use of recyclable or sustainable materials to reduce energy consumption and waste generation, in line with the environmental philosophy and social responsibility of modern companies.

Application Of Mezzanine Floor

Warehouse storage: The mezzanine floor is an indispensable part of the warehouse and is used to store all kinds of goods. Through reasonable rack layout and design, you can maximize the use of warehouse space, improve storage density and efficiency.

Logistics distribution: In the logistics distribution center, the mezzanine floor is used for sorting, packaging and temporary storage of goods for distribution. Efficient racking systems can speed up logistics, reduce error rates and improve customer satisfaction.

Cold chain storage: For goods that need to be refrigerated or frozen, such as food, medicine, etc., the mezzanine floor needs to have cold-resistant, anti-corrosion and other characteristics to ensure the quality and safety of the goods during storage.

Production workshop: In the production workshop of the manufacturing industry, the mezzanine floor is used to store and organize the items required for production such as materials, parts and tools. Through a reasonable rack layout and marking system, production efficiency can be improved and search time reduced.

Finished goods warehouse: Manufacturing enterprises need finished goods warehouse to store finished products. The mezzanine floor can be designed and configured according to the characteristics and storage needs of the product, ensuring the safe and orderly storage of the finished product.

Frequently Asked Questions About Mezzanine Floor

Mezzanine floor significantly increase vertical space utilization by installing additional storage layers at the top or higher of the warehouse. They can be customized to the specific size and height of the warehouse, ensuring that every inch of space is used efficiently. With proper planning, mezzanine floor can increase storage space by 50% or more.

The mezzanine floor is designed and constructed in strict compliance with relevant safety standards and specifications. They usually use strong steel or aluminum alloy as the main structural material, able to withstand heavy loads and resist deformation. In addition, safety facilities such as guardrail, non-slip floor and emergency evacuation passages will be installed to ensure the safety of personnel and cargo.

The load-bearing capacity of the attic platform is determined by its design, material selection and structural strength. In the design phase, engineers will consider the actual use of the warehouse, the weight and distribution of the stored items, as well as the impact of natural factors such as earthquakes and wind pressure, to calculate the appropriate load-bearing capacity. Customers can choose the appropriate bearing specifications according to their own requirements.

The design of the mezzanine floor will fully consider the ventilation and lighting needs of the warehouse. Ventilation vents, skylights, or lighting devices can be properly installed to ensure adequate air circulation and light in the warehouse. In addition, transparent or translucent materials can also be selected as the ceiling of the mezzanine floor to increase the range of natural light exposure.

The installation of mezzanine floor is usually carried out by a professional construction team with extensive experience and expertise to ensure a smooth and reliable installation process. As for maintenance, the mezzanine floor is relatively simple, mainly including regular inspection of structural stability, cleaning and maintenance of guardrail, floor and other components. Regular maintenance can extend the life of the mezzanine floor and maintain its good performance.

Yes, the mezzanine floor supports custom service. Because each warehouse is different in size, height, use and storage needs, it needs to be customized according to the actual situation. Customized services can meet the specific needs of customers, ensuring that the mezzanine floor is perfectly integrated into the warehouse environment, and improving the overall use effect.

Mezzanine floor often improve storage efficiency and space utilization in warehouses, which has a positive impact on daily operations. They can reduce the occupation of the ground storage area and make the warehouse layout more reasonable and orderly. In addition, the mezzanine floor can also facilitate the classification management and rapid access to goods, improving warehouse response speed and customer satisfaction.

The service life of a mezzanine floor depends on a number of factors, including material quality, design rationality, construction quality, and daily maintenance. Generally speaking, if the use of high-quality materials and reasonable design, and regular maintenance, the service life of the mezzanine floor can reach more than ten years. Of course, the specific service life needs to be evaluated according to the actual situation.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!