Cantilever Racking System

What Is Cantilever Racking System

Cantilever racking system is a special type of storage rack, mainly used to store long materials, ring materials, plates, pipes and irregular goods. The system uses special profiles as the base material, through the column, beam, cantilever beam, connecting rod and other components combined to form a stable and reliable bearing structure. It is characterized by the forward design of the cantilever beam, which can greatly improve the utilization rate and work efficiency of the warehouse. The cantilever can be single-sided or double-sided, flexibly configured according to storage requirements.

Cantilever Racking System Features

The structure is stable and reliable: the cantilever rack system adopts the combined structure, the column and the cantilever beam have excellent material, strong bearing capacity and stable structure.

High space utilization: The forward cantilever design can make full use of the warehouse space, especially for long or irregular materials, and increase the storage capacity of the warehouse.

Easy management: The cantilever rack system has a wide vision, and managers can easily view and access the goods, improving work efficiency.

Strong flexibility: the cantilever rack system can be disassembled, transported, adjusted and moved according to actual needs to adapt to different storage needs.

Strong load: The cantilever beam and column design of the cantilever rack system is reasonable, and the bearing capacity is strong, which can meet the storage needs of various heavy materials.

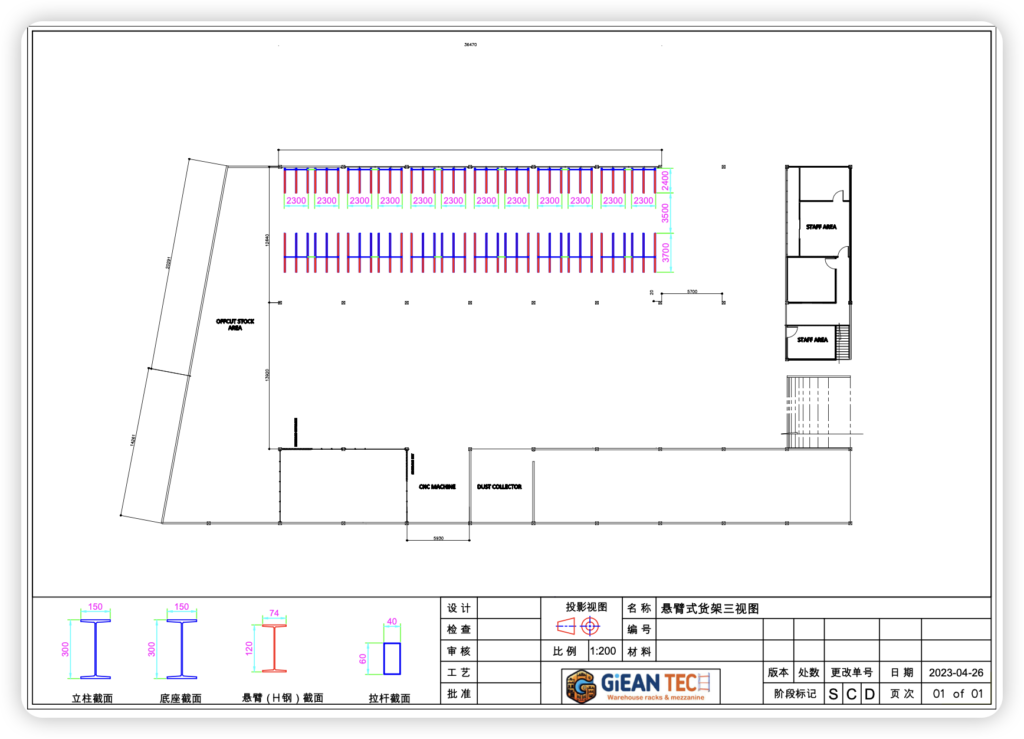

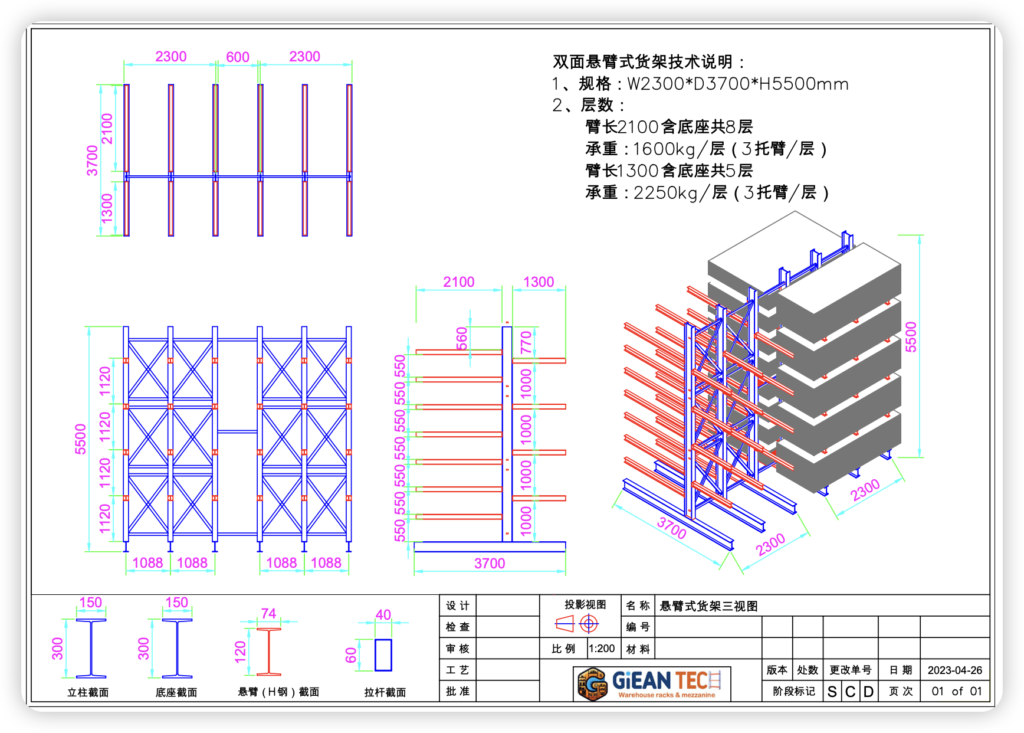

The Process Of Giean Cantilever Racking System Drawing Design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Selective Pallet Racking System

1.High-strength materials: Giean cantilever rack are usually made of high-strength steel, or even alloy steel. The beam and column sections of the cantilever are carefully designed to ensure that they can withstand considerable weight and pressure, and are suitable for storing heavy, long materials such as steel pipes, wood, and plates.

2.Modular design: The Giean cantilever racking system usually adopts a modular design, and the cantilever length, height, column distance, etc., can be flexibly adjusted according to actual needs. This allows the cantilever rack to adapt to different storage needs, especially when storing items of different lengths or shapes.

3.Safety design: Giean cantilever rack design also considers safety, such as anti-slip design, anti-overturn design, etc., to ensure that the goods will not easily slip or dump when stored and accessed, reducing the risk of accidents.

4.Adaptable to a variety of environments: Giean cantilever rack are not only suitable for indoor warehouses, but also for outdoor environments. By adding appropriate anti-corrosion coatings and protective measures, the cantilever rack can be used in different climatic conditions and withstand wind, sun and rain.

5.Cost effective: Although the initial investment in cantilever rack may be high, they significantly reduce warehouse management costs in the long run due to their durability and flexibility. The hidden costs of wasted space and damaged goods are reduced.

Application Of Cantilever Racking System

Improve storage efficiency: The cantilever rack can make full use of the vertical space of the warehouse, suspend the aluminum profile for storage, reduce the ground occupation area, and improve storage density and storage efficiency.

Easy access: The design of the cantilever rack makes the access of aluminum profiles convenient and fast, and workers can easily find and remove the required aluminum profiles, improving work efficiency.

Aluminum profile protection: The cantilever rack can avoid direct contact between aluminum profiles and the ground or other objects, reduce the risk of wear and scratches, and protect the surface quality of aluminum profiles.

Beautiful and neat: The appearance of the cantilever rack is simple and generous, which can improve the overall image of the warehouse and make the warehouse environment more beautiful and tidy.

Efficient storage: The cantilever rack can efficiently store wood, make full use of warehouse space, and improve storage efficiency.

Easy to manage: The design of the cantilever rack makes access to the wood easy and fast, which helps the daily management of the warehouse and the quick turnover of the goods.

Protect wood: The cantilever rack can avoid direct contact between the wood and the ground or other objects, reduce the risk of wear and damage, and protect the integrity and quality of the wood.

Improve warehouse image: The appearance of the cantilever rack is clean and beautiful, which can enhance the overall image of the warehouse and create a professional storage environment.

Flexible layout: The design of the cantilever rack allows for flexible layout according to the actual space size of the warehouse and the size of the abandoned car, ensuring that every inch of space can be fully utilized.

Fast access: The design of the cantilever rack makes the access of the abandoned car convenient and fast, the operator can quickly locate and access the required vehicle, and improve the turnover efficiency of the warehouse.

Avoid direct contact: The cantilever rack can avoid the direct contact between the abandoned car and the ground or other objects, and reduce the damage caused by friction, collision and other reasons. It is of great significance to maintain the integrity and value of used cars.

Stable support: The stable structural design of the cantilever rack ensures that the abandoned car remains stable during storage, preventing the vehicle from tilting or collapsing due to gravity.

The following factors need to be considered when selecting the appropriate cantilever racking system

Include the ground bearing capacity, space size, and height restrictions of the warehouse.

The size, weight, frequency of access and whether special storage conditions (such as temperature and humidity control) are required.

Whether there is a suitable handling equipment (such as forklift, stacker, etc.) and the operation requirements of the equipment.

The cost of cantilever rack is a complex concept, which is affected by many factors, including material cost, design cost, processing cost, installation cost and other costs.

Frequently Asked Questions About Cantilever Racking System

The cantilever rack system is particularly suitable for storing long, tubular, irregular or heavy goods such as pipes, wood, bars, profiles, steel, aluminum, plastic pipes, long shafts, etc. Its design allows goods to be hung horizontally on racks, making efficient use of the vertical space of the warehouse while facilitating access.

The load-bearing capacity of cantilever racks depends on its material (such as cold rolled steel, hot rolled steel, etc.), structural design and installation quality. In general, the load-bearing capacity of a single cantilever can range from a few hundred kilograms to several tons, which can meet most industrial and commercial storage needs. Customers can customize cantilever racks according to specific cargo weight and storage needs.

The installation of cantilever racks is relatively simple, usually assembled and fixed by a professional team according to the design drawings. In terms of maintenance, it is mainly to regularly check whether the connector is loose, whether the coating is intact and whether the rack is deformed, etc., and to deal with it in time. Keeping the racks clean and dry also helps extend their service life.

The cantilever rack makes full use of the vertical space of the warehouse by hanging the goods horizontally, avoiding the waste of ground space. At the same time, its flexible layout design can be adjusted according to the actual situation of the warehouse and storage needs to maximize space utilization. In addition, cantilever racks can also be combined with other types of rack systems (such as beam racks, attic racks, etc.) to form a multi-level, multi-dimensional storage solution.

The safety of cantilever racks is mainly guaranteed by design rationality, material quality, installation process and daily use management. The weight, size and access mode of the goods should be considered in the design to ensure the stability of the rack structure; Use high-quality materials and accessories to improve the bearing capacity and durability of the rack; Installation by a professional team to ensure installation quality; Avoid overloading, collision and other improper operations in daily use, and check and maintain regularly.

Yes, the cantilever rack system supports a high degree of customization. Customers can negotiate with suppliers to customize the appropriate cantilever rack system according to the specific size of the warehouse, the type of goods, storage needs and budget factors. The length, quantity, load-bearing capacity, material, color and layout of the entire system can be customized according to customer requirements.

The access efficiency of cantilever racks is relatively high, especially for long or heavy goods. Because its design allows goods to be hung horizontally on racks, there is no need to move other goods during access, reducing handling time and labor costs. At the same time, the number of layers of the cantilever rack can be adjusted according to needs, increasing the storage density and further improving the access efficiency.

The cost effectiveness of a cantilever racking system depends on a number of factors, including the material, size, quantity, customization, and installation and maintenance costs of the rack. Although the initial investment may be relatively high, in the long term, the cantilever rack system can bring significant economic benefits to customers by improving warehouse space utilization, reducing handling costs, and reducing the rate of cargo damage. In addition, its flexibility and scalability also enable the system to adapt to possible future changes in demand, further enhancing its cost-effectiveness.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!