Automated Storage&Retrieval Systems

What Is Automated Storage&Retrieval Systems

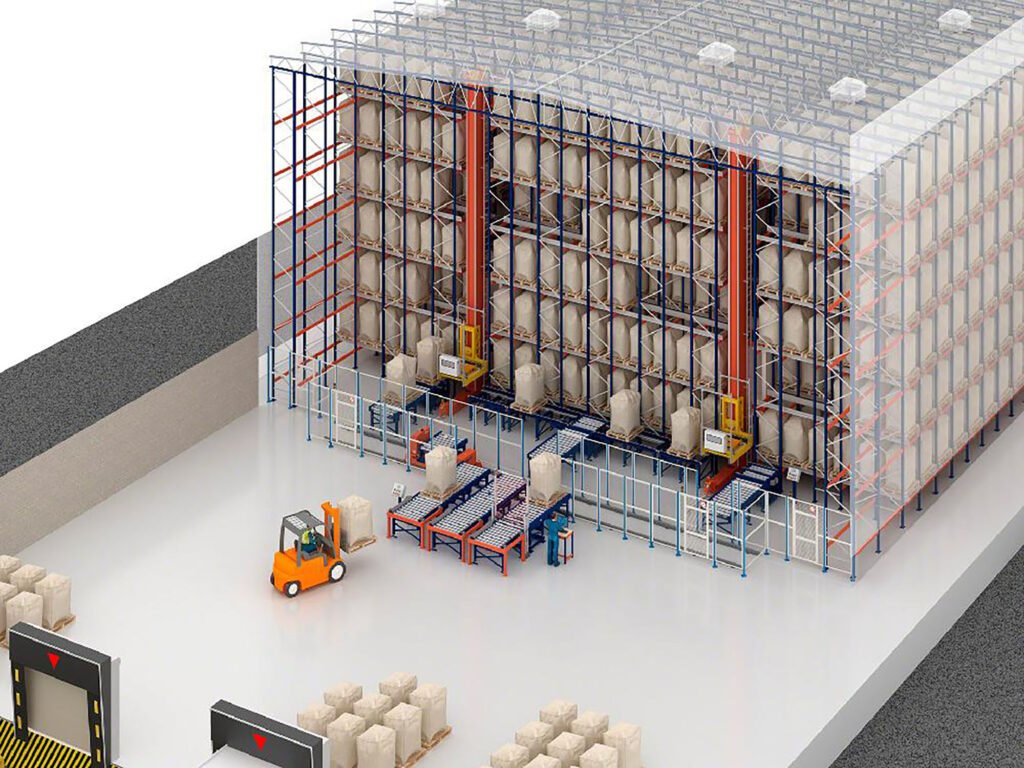

An Automated Storage and Retrieval System (AS/RS) is a high-tech warehouse solution that uses automated machines, such as robots and shuttles, to efficiently store and retrieve goods. This system optimizes space utilization, increases inventory accuracy, and enhances operational efficiency by minimizing manual handling and streamlining the storage process in various industrial environments.

Working principle and composition of AS/RS system

The working principle of AS/RS system is mainly based on computer control and automation technology. When the goods are stored, the system first identifies the information of the goods through the information identification system, and matches it with the data in the inventory management system. Then, according to the storage needs of the goods, the computer control system dispatches the stacker to move the goods to the designated cargo location. When the goods need to go out of storage, the system will also dispatch the stacker to remove the goods from the rack according to the outbound instructions, and transport them to the outlet area through the conveyor system.

The process of Giean warehouse storage solution drawing design

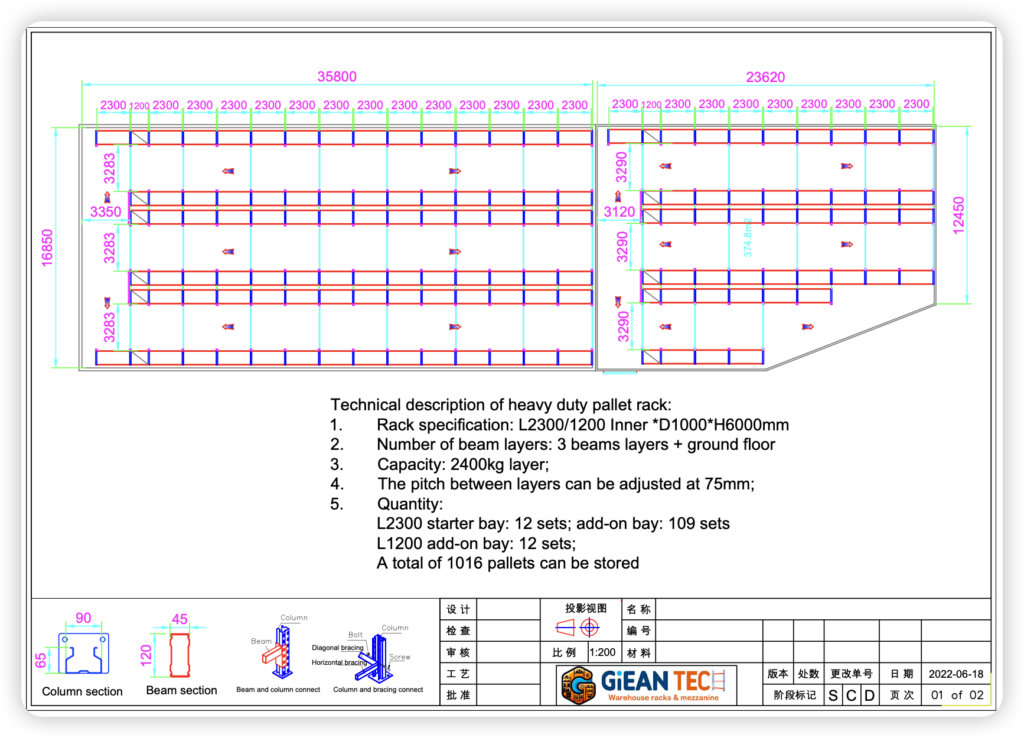

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

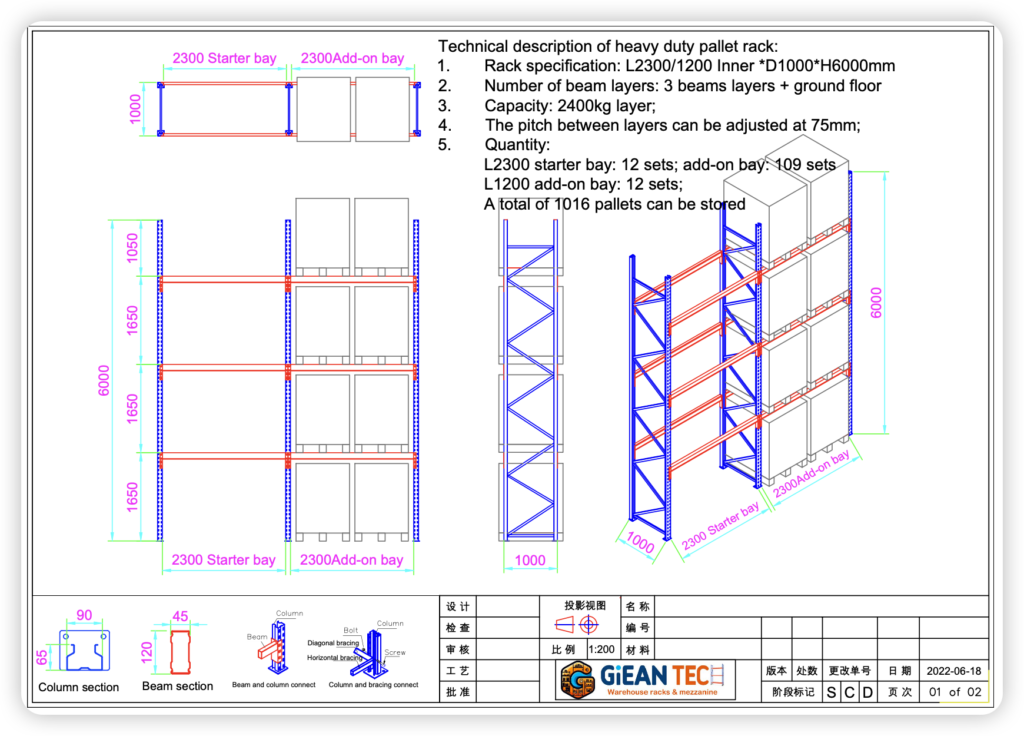

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

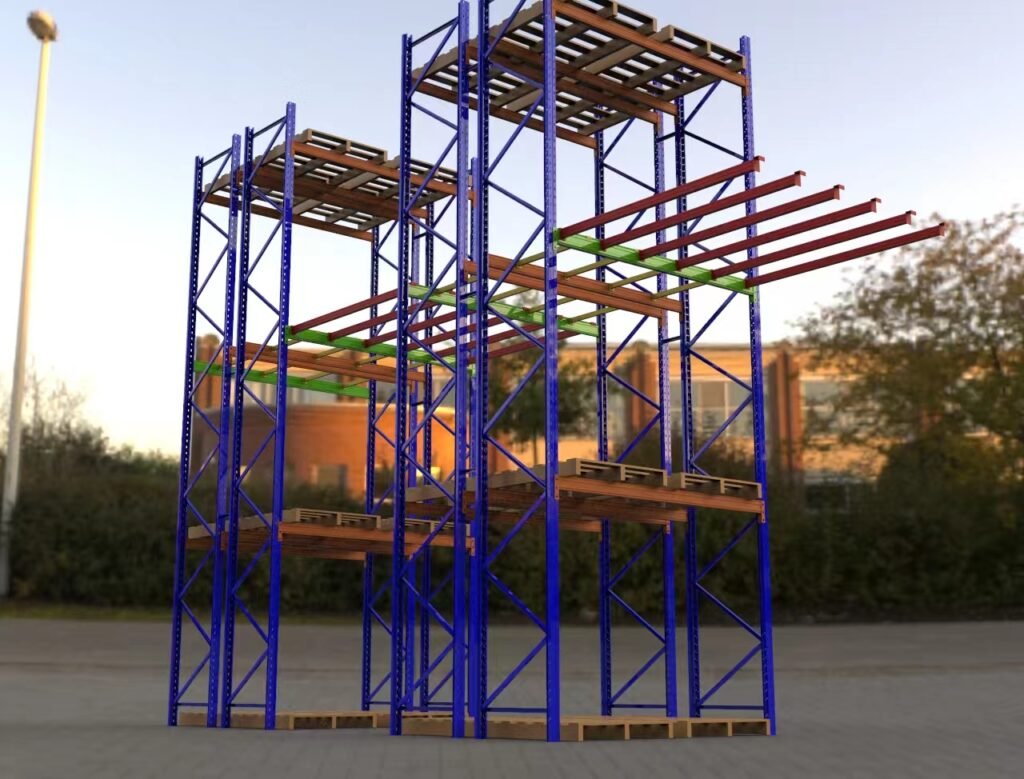

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

The composition of Automated Storage&Retrieval Systems

1. High-rise rack: used to store goods, make full use of vertical space, improve storage density.

2. Stacker: such as roadway stacker, bridge stacker, etc., responsible for the automatic handling of goods between shelves.

3. Conveying system: including roller conveyors, chain conveyors, etc., used to transport goods from the inlet area to the rack, or from the shelf to the outlet area.

4. Information identification system: identification of cargo information through RFID, bar code and other technologies.

5. Computer control system: centralized control and management of the entire system to achieve online control of equipment.

6. Communication system: To ensure the smooth transmission of information between the components of the system.

7. Monitoring system: real-time monitoring of the operating status of the system to ensure the safe and stable operation of the system.

8. Management system: to manage the inventory information, to achieve data collection, analysis and processing.

Why Choose Giean Automated Storage&Retrieval Systems

Deep technical accumulation: Our company has many years of research and development and production experience in the field of automated warehousing, and the technical team is composed of senior experts in the industry to ensure the stability and advancement of the AS/RS system.

Continuous technological innovation: We continue to invest R & D resources and introduce the latest technological achievements, such as AI algorithm optimization, Internet of Things technology, big data analysis, etc., to improve the intelligence level and work efficiency of the system.

Diversified product range: We provide various forms of AS/RS system including unit, through, circulating, etc., to meet the needs of customers in different industries and different scales.

Customized solutions: According to the specific needs of customers, we provide one-stop customized services from design, planning, manufacturing to installation and commissioning to ensure that the system perfectly matches the customer’s business scenario.

Efficient operation capability: Our AS/RS system can quickly and accurately complete cargo access operations, reducing cargo handling time and improving overall operational efficiency. Especially during peak hours, the advantages of automated systems are more obvious.

Refined inventory management: Through the integration with the warehouse management system (WMS), to achieve refined inventory management, accurate record of inventory changes, improve inventory accuracy.

Reduce labor costs: Automated systems reduce the reliance on labor and reduce labor costs. At the same time, due to the reduction of human error, further improve the work efficiency.

Rapid return on investment: Although the initial investment of AS/RS systems is large, in the long term, its improved operational efficiency and reduced operating costs can bring rapid return on investment.

Improved safety: Automated warehouses reduce employee access to warehouse areas and reduce the risk of workplace accidents. At the same time, by setting a variety of safety protection measures, such as obstacle detector, emergency stop button, etc., to further ensure the safe operation of the warehouse.

Energy saving and environmental protection: Advanced automated warehouses usually use energy-saving technologies, such as LED lighting, intelligent control systems, etc., to reduce energy consumption and reduce operating costs. In addition, by optimizing the operation process to reduce unnecessary transportation distance, indirectly reduce carbon emissions, in line with the concept of sustainable development.

Professional customer service: We have a professional customer service team, able to provide customers with timely and professional consultation and solutions.

Comprehensive after-sales support: We provide comprehensive after-sales support services including system maintenance, troubleshooting, upgrading and updating to ensure that customers have no worries during use.

The following factors need to be considered when selecting the automated storage and retrieval system

Including the geographical location of the warehouse, spatial layout, building structure and environmental conditions. Ensure that the warehouse is suitable for the installation and operation of the AS/RS system, such as sufficient height, stable floor, appropriate temperature and humidity control, etc.

Including system investment costs, operating costs and maintenance costs. The overall cost of the AS/RS system needs to be evaluated in detail and compared with the expected benefits to ensure the economic viability of the project. At the same time, we also need to consider the long-term operation of energy consumption, labor costs and equipment depreciation and other factors.

Refers to the size, weight, shape, packaging and storage requirements of the goods. These factors will directly affect the design of the shelf, the selection of equipment and storage efficiency. For example, heavy goods require more robust racking and lifting equipment, while goods of varying sizes may require more flexible storage solutions.

Refers to the hardware equipment required for automated warehousing systems, such as stackers, conveyors, sorting systems, information management systems, etc. Select an appropriate device based on the warehouse scale, product features, and service requirements, and ensure device compatibility and stability.

Frequently Asked Questions About automated storage and retrieval system

Yes, AS/RS systems can greatly increase the storage density of warehouses by utilizing vertical space, adopting high-rise shelves and automated equipment such as stackers, thus storing more goods in the same footprint.

The AS/RS system automates access to goods, reducing the time and labor required for manual handling and retrieval. This not only reduces direct labor costs, but also improves the safety of the work environment and reduces losses due to human error.

While AS/RS systems offer a high degree of flexibility, certain cargo types and packages may require specific adapters or modifications to accommodate automated handling. For example, heavy, oversized or irregularly shaped cargo may require specially designed handling equipment or storage solutions.

AS/RS systems are usually equipped with advanced control systems and sensors, which can accurately control the movement of the equipment, and accurately identify and track the goods through barcode, RFID and other technologies, thus ensuring efficient and accurate access operations.

The complexity of maintenance and maintenance depends on the specific configuration and complexity of the system. In general, manufacturers provide maintenance manuals and training programs to help users understand and perform basic maintenance tasks. For complex problems, professional intervention may be required.

The evaluation of ROI needs to take into account a number of factors, including the acquisition cost of the system, operating costs (such as energy, maintenance, etc.), improved storage efficiency, reduced labor costs, reduced inventory cycles, etc. Financial analysis tools, such as ROI calculators, can be used to assess the expected return on investment.

Most modern AS/RS systems are designed with open interfaces for easy integration with various warehouse management systems (WMS). This can be achieved through standard data exchange protocols (such as EDI, XML, etc.) to achieve real-time synchronization of inventory data, order information, etc.

Yes, AS/RS systems usually have emergency handling functions, such as emergency stop buttons, backup power systems, etc., to ensure rapid response and protection of personnel and equipment in emergency situations such as power outages, equipment failures, etc. In addition, the system is regularly troubleshooting and maintenance to reduce the risk of sudden failure.