AGV Vehicle

What Is AGV Vehicle

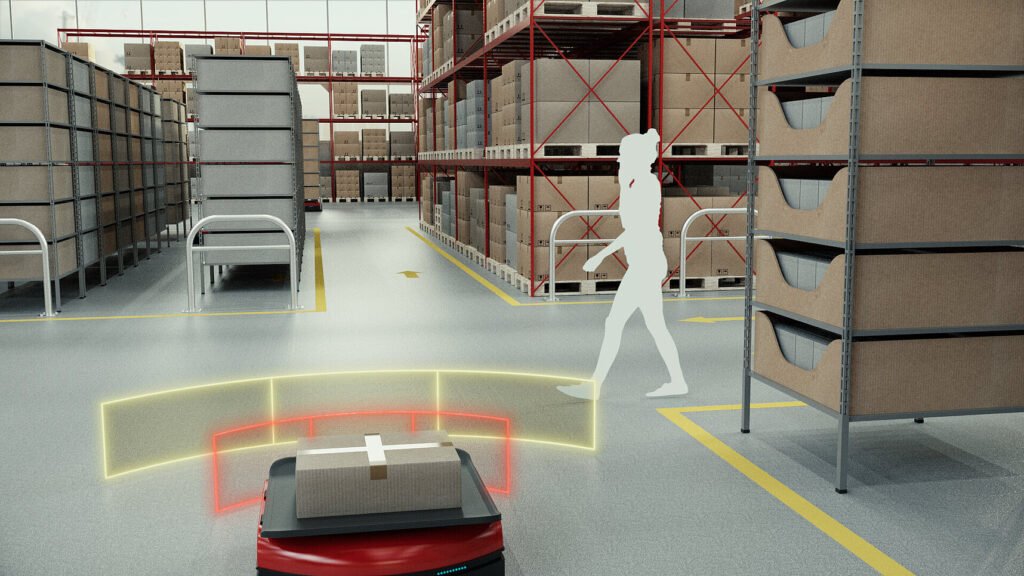

Definition: AGV is the abbreviation of Automated Guided Vehicle, meaning “automated guided transport vehicle”. It is an unmanned transport equipment, equipped with automatic guidance devices such as electromagnetic or optical, which can travel along the specified guidance path, and has safety protection and various load shifting functions

Features of AGV "automated guided transport vehicle"

Highly automated and intelligent:

AGV has automatic guidance, automatic positioning, path planning, obstacle avoidance and other functions to achieve efficient and accurate material handling.

Strong flexibility:

The AGV’s driving path can be flexibly adjusted according to actual needs, and the path adjustment cost is lower than that of traditional conveyor belts and rigid transmission lines.

Environmental protection and energy saving:

AGV relies on its own battery to provide power, no noise, no pollution during operation, suitable for places with high environmental requirements.

Driverless:

The AGV is driverless through an automatic guidance device, without manual operation.

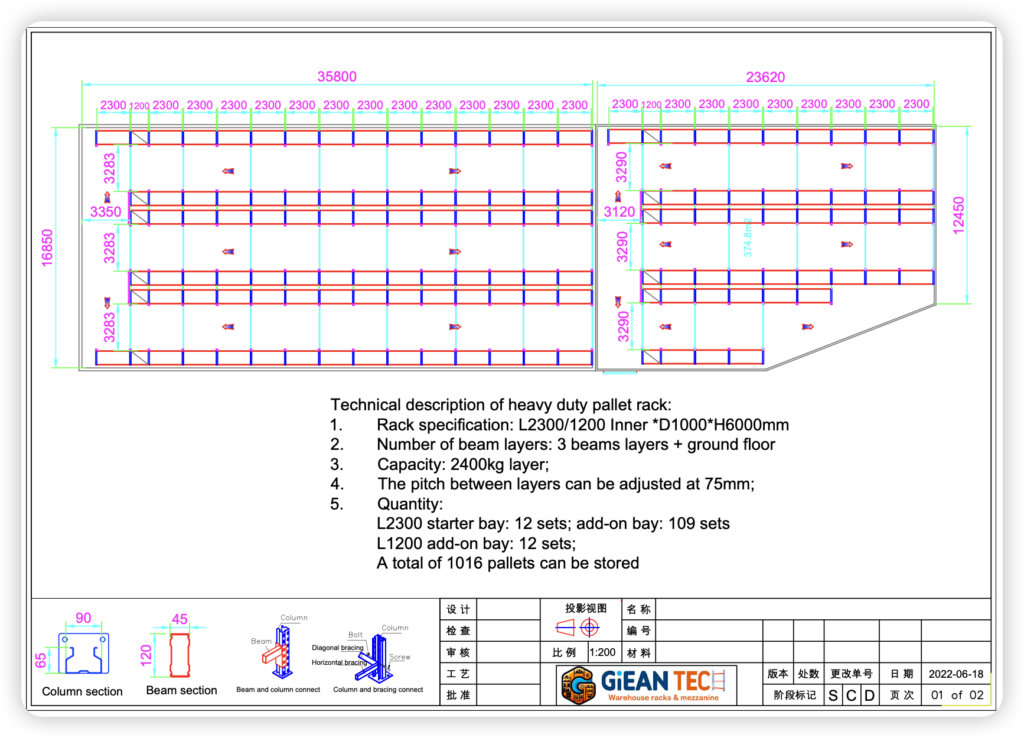

The process of Giean warehouse storage solution drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

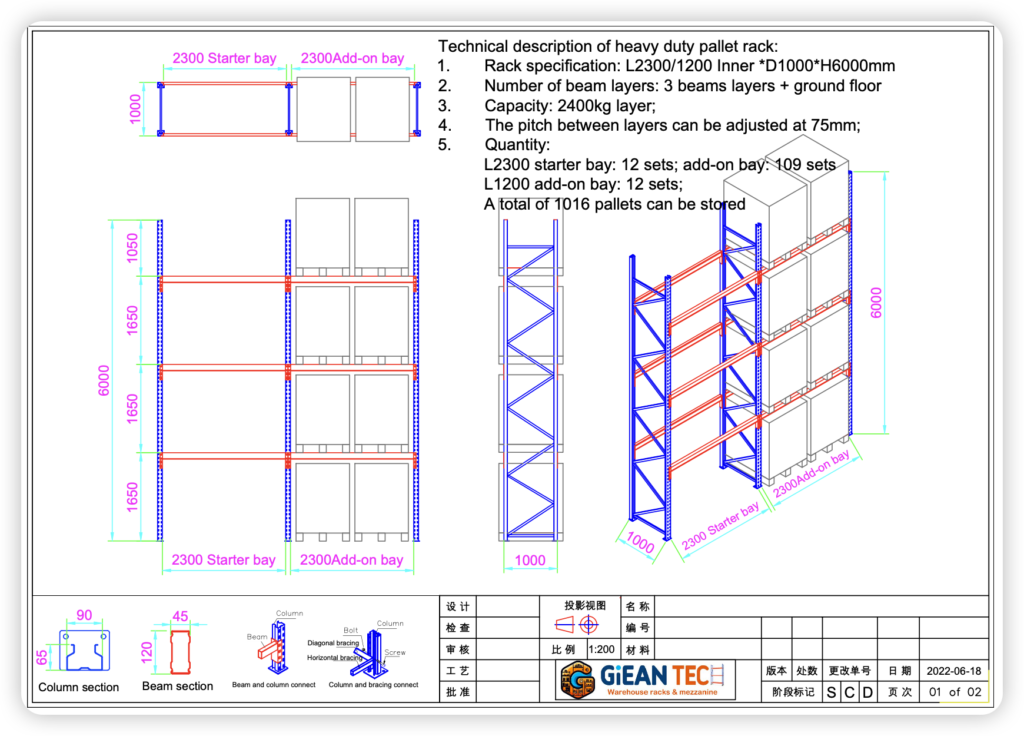

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

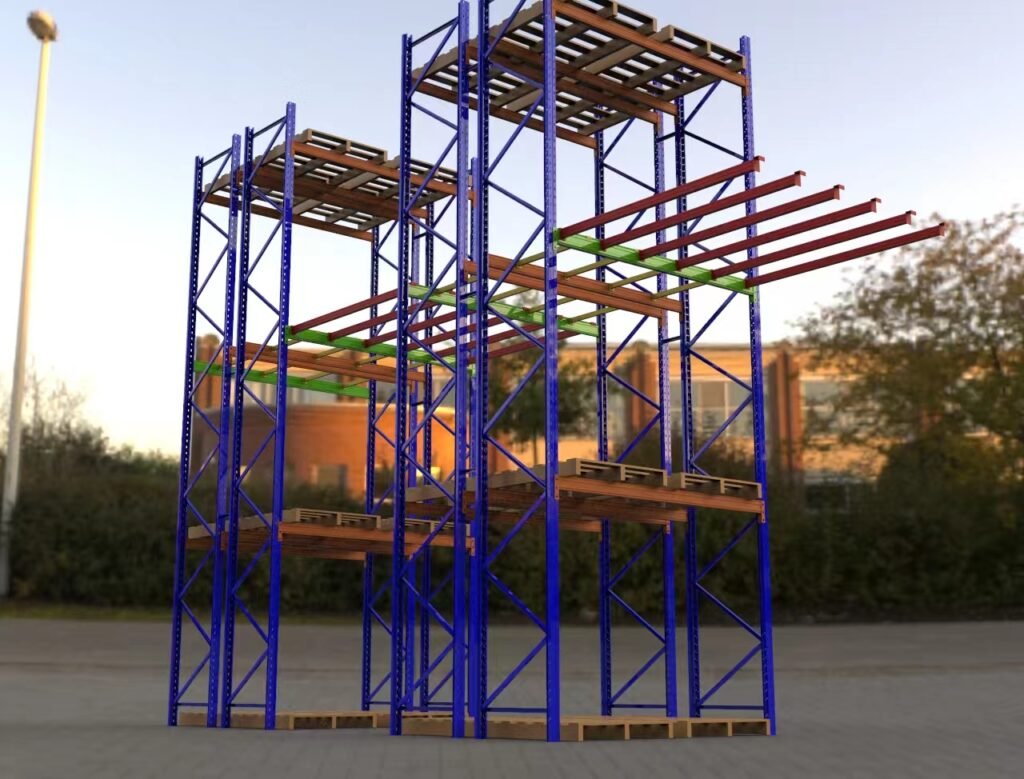

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean "automated guided transport vehicle"

Efficient automation: Our AGVs can automatically navigate and move cargo, reducing manual operations and significantly increasing work efficiency.

Safe and reliable: built-in multiple safety protection to avoid collisions and accidents, to ensure the safety of personnel and goods.

Cost savings: In the long term, AGVs can significantly reduce labor costs, and maintenance costs are relatively low.

Flexible adaptation: The path and operation mode can be flexibly adjusted according to different environments and requirements to meet diverse application scenarios.

Widely used: suitable for industrial production, logistics warehousing and other fields to improve the overall operational efficiency.

Application Of "automated guided transport vehicle"

Manufacturing Industry:

In manufacturing production lines, AGVs (Autonomous guided Vehicles) perform a variety of tasks, including material handling, assembly and inspection. They can precisely transport raw materials, parts and finished products between production lines, reducing the time and labor of manual handling. At the same time, AGVs can also work with assembly robots or other automation equipment to automatically complete assembly tasks and ensure the consistency and accuracy of product assembly. In addition, the AGV can also be equipped with inspection devices for product quality inspection or process monitoring, and timely detection of production problems, thereby improving production efficiency and quality levels.

Warehousing and Logistics:

In the field of warehousing and logistics, AGVs can automatically complete tasks such as the handling, sorting and palletizing of goods. They can freely shuttle within the warehouse, according to preset routes and instructions, accurately move goods from the shelves to the exit reservoir or sorting area. Agvs can also work seamlessly with smart warehousing systems to automatically sort goods based on order information and palletize them to a designated location. This can not only reduce labor costs, but also improve the efficiency and accuracy of warehousing logistics, reducing the risk of damage and loss of goods.

Medical field:

In the medical field, AGVs can automatically transport and distribute medical supplies such as medicines and equipment. According to the order information of the hospital or the prescription of the doctor, the medical supplies such as drugs and instruments can be automatically transported from the pharmacy, equipment warehouse and other places to the wards, operating rooms or outpatient departments. This can not only reduce the manual handling time of medical personnel, but also ensure the safety and timeliness of medical materials, and improve the efficiency and quality of medical services. At the same time, AGVs can also reduce the contact between medical personnel and medical supplies, reduce the risk of cross-infection, and ensure the safety of medical personnel and patients.

Frequently Asked Questions About automated guided transport vehicle

AGVs typically sense their surroundings through built-in sensors (such as lidar, cameras, ultrasonic sensors, etc.) and navigation algorithms, and navigate autonomously according to a preset map or path. These sensors can collect environmental information in real time, such as distance, direction, obstacles, etc., and then the navigation algorithm will calculate the optimal driving path based on this information, and control the AGV to travel along that path.

Yes, AGVs can work in conjunction with various automation devices such as robots, conveyor belts, lifts, etc. By integrating advanced communication technology and control systems, AGVs can be seamlessly integrated with other equipment to complete complex production tasks or logistics operations.

In the manufacturing industry, AGV can be applied to material handling, assembly, testing and other links. They can accurately transport raw materials, components and finished products, work with assembly robots to complete assembly tasks, and carry inspection devices to perform quality checks on products. These applications can significantly improve production efficiency and quality levels.

In warehousing logistics, AGVs can automatically complete tasks such as the handling, sorting and palletizing of goods. They can replace manual heavy, repetitive and monotonous handling work, thus significantly reducing labor costs. At the same time, AGVs can also improve the efficiency and accuracy of warehousing logistics, reducing the risk of damage and loss of goods.

In places such as airport stations, AGVs can automatically handle and transport luggage and cargo. They can transport luggage and cargo precisely to the designated location based on the passenger’s baggage information or the destination of the cargo. This can reduce the time and labor of manual handling, improve the efficiency of baggage and cargo handling, and reduce the risk of baggage loss and delay.

In the medical field, AGV can be applied to the automatic handling and distribution of medical materials such as drugs and equipment. They can accurately transport medical supplies from pharmacies, device warehouses and other places to wards, operating rooms or outpatient departments according to the order information of the hospital or the prescription of the doctor. In this way, the manual handling time of medical staff can be reduced, and the efficiency and quality of medical services can be improved.

Compared with traditional manual handling equipment, the maintenance and maintenance of AGVs is relatively simple. They usually have advanced fault diagnosis and alarm functions, which can monitor the operating status and performance parameters of the equipment in real time. When the equipment fails or needs maintenance, the system will send an alarm message in time, prompting the maintenance personnel to deal with it. At the same time, the maintenance and maintenance of AGVs can also be carried out through remote monitoring and control systems, reducing maintenance costs and time.

The return on investment of AGVs depends on a number of factors, such as equipment cost, application scenarios, and the degree of productivity improvement. In general, for places that require a lot of manual handling and logistics operations (such as manufacturing, warehousing logistics, airport stations, etc.), the return on investment of AGVs is usually higher. By reducing labor costs, improving production efficiency and quality levels, AGV can bring significant economic benefits to enterprises in a short time. Of course, the specific return on investment also needs to be evaluated and calculated according to the actual situation of the enterprise.