Other Material Handling Equipments

Material Handling Equipments Types

Wire Container

A wire container, also known as a storage cage or wire mesh container, is a durable, collapsible storage solution used in warehouses and logistics. Constructed from sturdy steel wire mesh, these containers provide secure storage while allowing visibility and ventilation for the stored goods. They are ideal for transporting, storing, and organizing bulk items, and can be stacked to maximize space. Wire containers are easy to move using forklifts, making them a versatile option for efficient inventory management and space optimization in industrial environments.

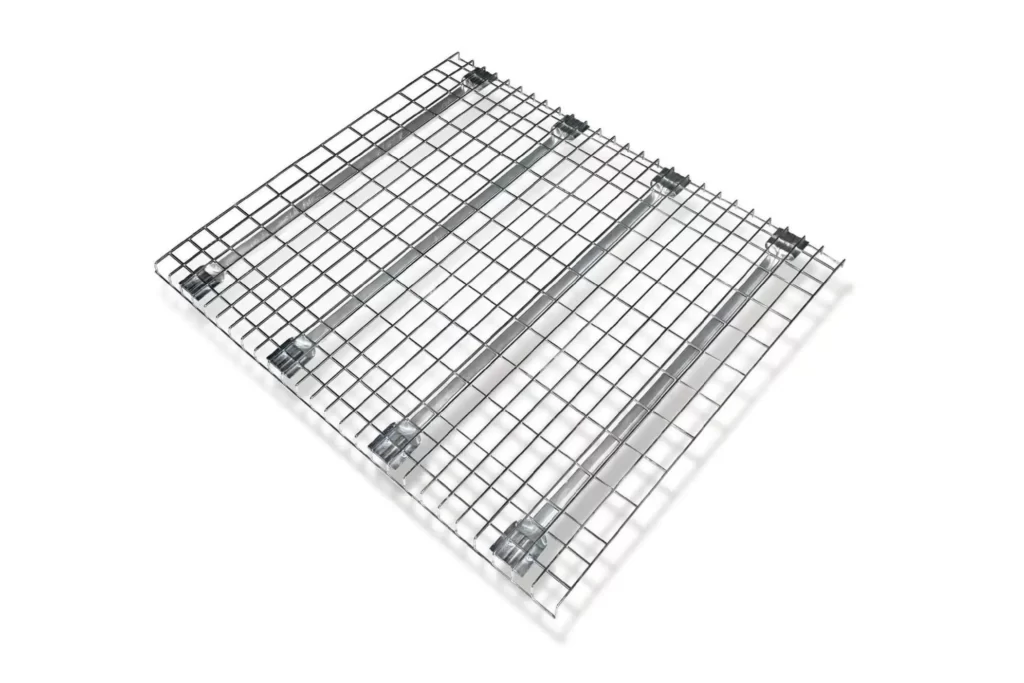

Wire Mesh Decking

Wire mesh decking is a durable racking accessory used in pallet rack systems to provide additional support and safety. Made from welded steel mesh, it fits between rack beams to create a strong, stable surface for storing pallets or smaller items. Wire mesh decking enhances airflow and visibility, reducing dust accumulation and improving fire safety by allowing sprinkler water to pass through. This decking is ideal for increasing load capacity and ensuring secure, organized storage in warehouses and industrial facilities.

Platform Trolley

A platform trolley is a versatile, flat-surfaced cart used to transport goods and materials in warehouses, factories, and retail environments. It features a sturdy platform, typically made of steel, mounted on wheels for easy mobility. Equipped with handles for steering, platform trolleys allow for the efficient movement of heavy or bulky items with minimal physical effort. Ideal for loading, unloading, and transporting goods, platform trolleys enhance operational efficiency and reduce manual handling in various industrial settings.

Roll Container

A roll container, also known as a logistics trolley, is a wheeled storage cage used for the efficient transportation and handling of goods in warehouses, retail, and distribution centers. Typically made from metal wire mesh, roll containers feature multiple sides and an open top, providing secure containment while allowing visibility of the contents. They are designed for easy mobility and can be collapsed or nested when not in use. Roll containers enhance logistics efficiency by facilitating safe and organized transport of products within supply chains.

Heavy Duty Workbench

The four-way shuttle rack system is an advanced automated warehousing solution that employs four-way traveling shuttles capable of moving freely in multiple directions (such as forwards, backwards, leftwards, rightwards, or vertically) within the racks to achieve flexible access to goods. This system combines efficient rack design with intelligent navigation technology, enabling rapid and accurate cargo handling and sorting in high-density storage environments. Through intelligent scheduling and control, the four-way shuttle rack system enhances warehouse space utilization and operational efficiency, representing a significant technological innovation in modern intelligent warehousing and logistics.

Chrome Wire Shelving

An Automated Guided Vehicle (AGV) is a self-driving, battery-powered vehicle designed to transport materials or products along a defined path within a facility without human intervention. Equipped with sensors, navigation systems, and safety mechanisms, AGVs can move autonomously, avoiding obstacles and navigating through pre-mapped areas to deliver goods efficiently and accurately. These vehicles streamline material handling processes, improve warehouse productivity, and enhance workplace safety, serving as a cornerstone of modern automated logistics and manufacturing systems.

Slotted Angle Rack

The four-way shuttle rack system is an advanced automated warehousing solution that employs four-way traveling shuttles capable of moving freely in multiple directions (such as forwards, backwards, leftwards, rightwards, or vertically) within the racks to achieve flexible access to goods. This system combines efficient rack design with intelligent navigation technology, enabling rapid and accurate cargo handling and sorting in high-density storage environments. Through intelligent scheduling and control, the four-way shuttle rack system enhances warehouse space utilization and operational efficiency, representing a significant technological innovation in modern intelligent warehousing and logistics.

Plastic Pallet

An Automated Guided Vehicle (AGV) is a self-driving, battery-powered vehicle designed to transport materials or products along a defined path within a facility without human intervention. Equipped with sensors, navigation systems, and safety mechanisms, AGVs can move autonomously, avoiding obstacles and navigating through pre-mapped areas to deliver goods efficiently and accurately. These vehicles streamline material handling processes, improve warehouse productivity, and enhance workplace safety, serving as a cornerstone of modern automated logistics and manufacturing systems.

Plastic Shelf Bin Organizer

The four-way shuttle rack system is an advanced automated warehousing solution that employs four-way traveling shuttles capable of moving freely in multiple directions (such as forwards, backwards, leftwards, rightwards, or vertically) within the racks to achieve flexible access to goods. This system combines efficient rack design with intelligent navigation technology, enabling rapid and accurate cargo handling and sorting in high-density storage environments. Through intelligent scheduling and control, the four-way shuttle rack system enhances warehouse space utilization and operational efficiency, representing a significant technological innovation in modern intelligent warehousing and logistics.

Supermarket Shelf

An Automated Guided Vehicle (AGV) is a self-driving, battery-powered vehicle designed to transport materials or products along a defined path within a facility without human intervention. Equipped with sensors, navigation systems, and safety mechanisms, AGVs can move autonomously, avoiding obstacles and navigating through pre-mapped areas to deliver goods efficiently and accurately. These vehicles streamline material handling processes, improve warehouse productivity, and enhance workplace safety, serving as a cornerstone of modern automated logistics and manufacturing systems.

Mobile Platform Ladder

The four-way shuttle rack system is an advanced automated warehousing solution that employs four-way traveling shuttles capable of moving freely in multiple directions (such as forwards, backwards, leftwards, rightwards, or vertically) within the racks to achieve flexible access to goods. This system combines efficient rack design with intelligent navigation technology, enabling rapid and accurate cargo handling and sorting in high-density storage environments. Through intelligent scheduling and control, the four-way shuttle rack system enhances warehouse space utilization and operational efficiency, representing a significant technological innovation in modern intelligent warehousing and logistics.