Shuttle Racking System

What Is Shuttle Racking System

Shuttle racking is a highly automated and high-density storage solution, especially suitable for modern warehouses that require large amounts of storage space optimization and fast access.

Main components:

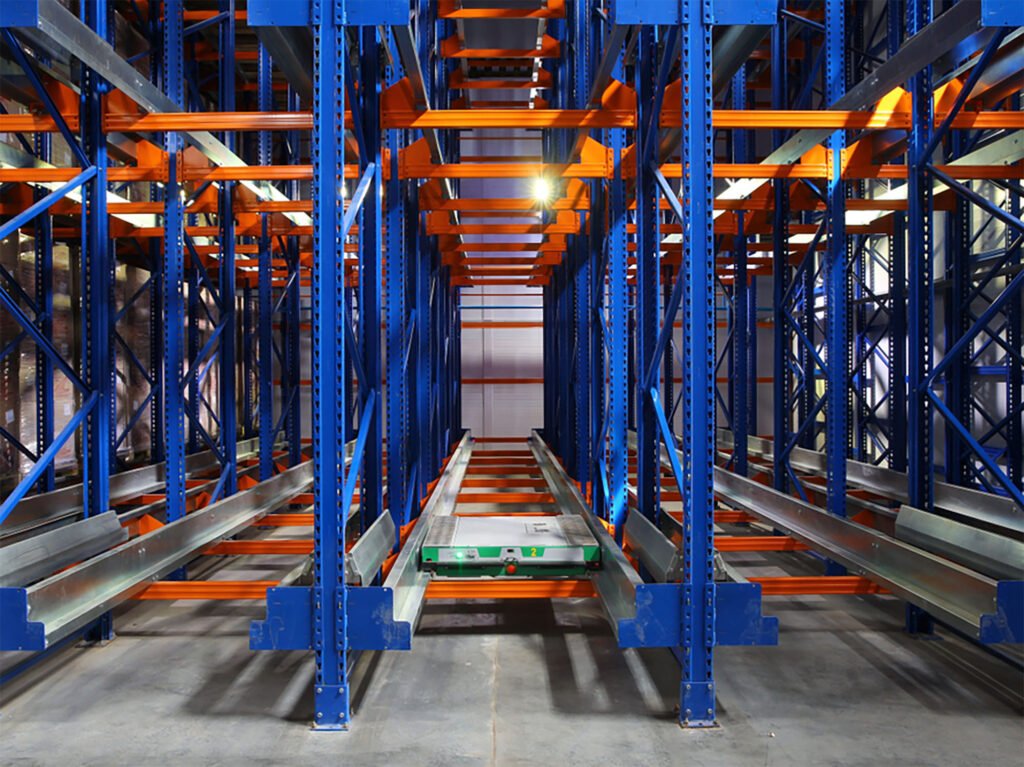

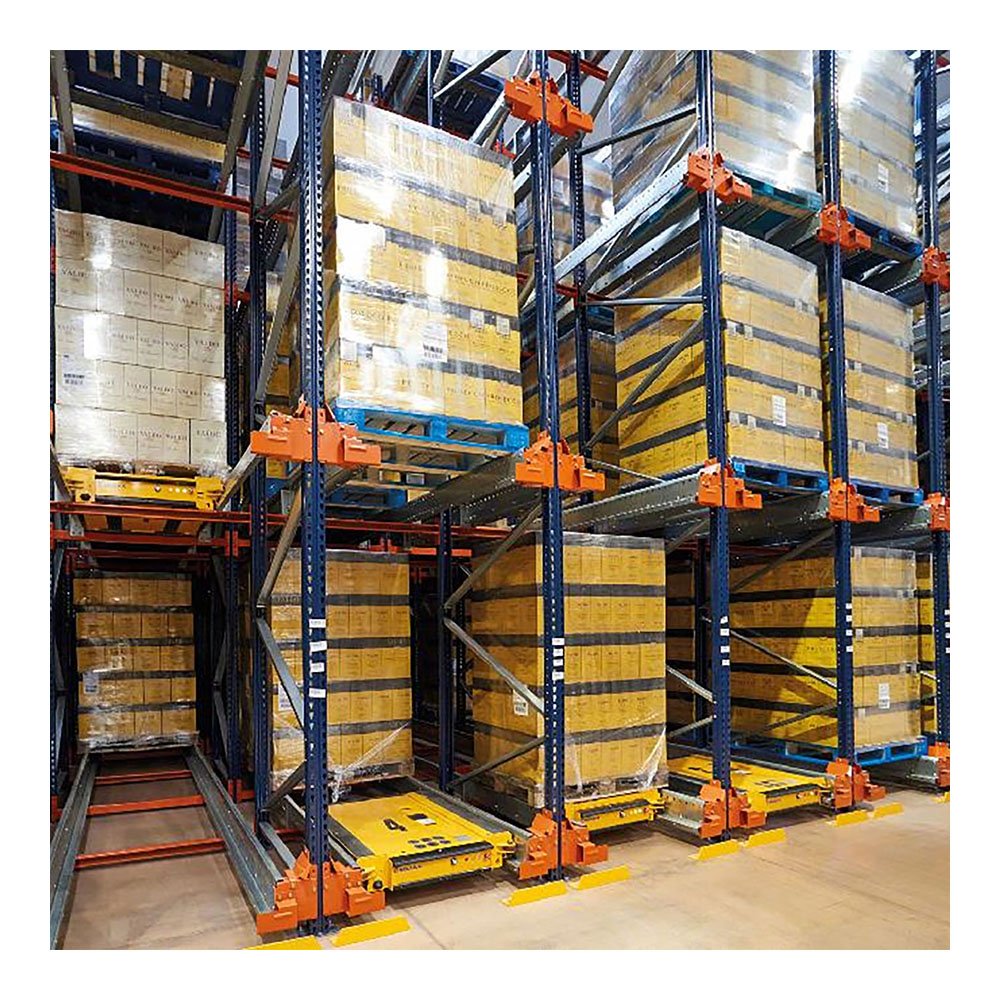

Racks: Consisting of multi-layered beams and upright, they are usually designed in the form of long-depth tunnels to accommodate the operation of shuttle vehicles.

Shuttle vehicle: A device that can be operated automatically or remotely on the inner track of the rack. It is responsible for transporting palletized goods in deep tunnels and realizing the access of goods.

1.High floor area ratio: In the warehouse of the same area, the floor area ratio of shuttle racks is much higher than that of ordinary racks. For example, the floor area ratio of the ordinary racks may be only 34%, while the floor area ratio of the shuttle racks can be as high as 75%, which is twice that of the ordinary racks.

Shuttle racking main features

2.Flexible access mode: Ordinary pallet racks can usually only meet the single access mode of first-in-first-out or first-in-last-out, while shuttle racks can achieve two access modes, which is more suitable for food, medicine and other industries with higher access requirements.

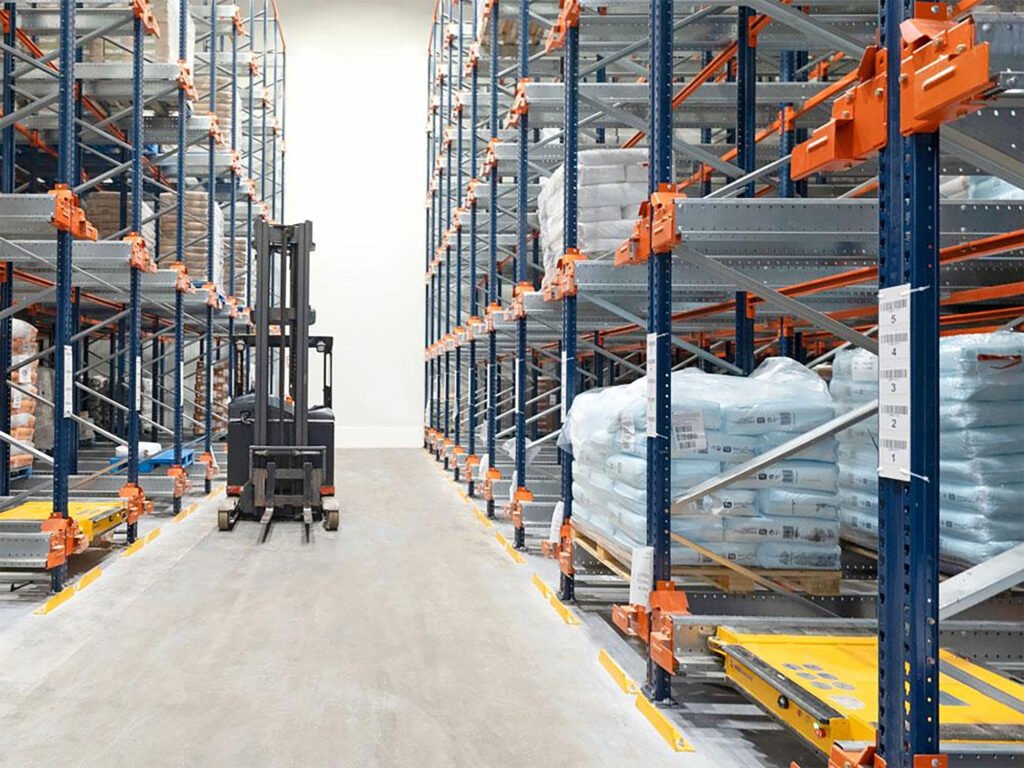

3.Efficient operation: In the shuttle rack system, the forklift does not need to enter the interior of the racks to access the goods, and a worker can operate multiple shuttle vehicles at the same time, greatly reducing the waiting time of the operation and improving the work efficiency.

4.The structure is stable and safe: the shuttle racking structure is very stable, and when the shuttle vehicle accesses the goods inside the racks, the forklift vehicle only needs to operate outside, avoiding the collision of the forklift vehicle on the racks, ensuring the safety of personnel and equipment.

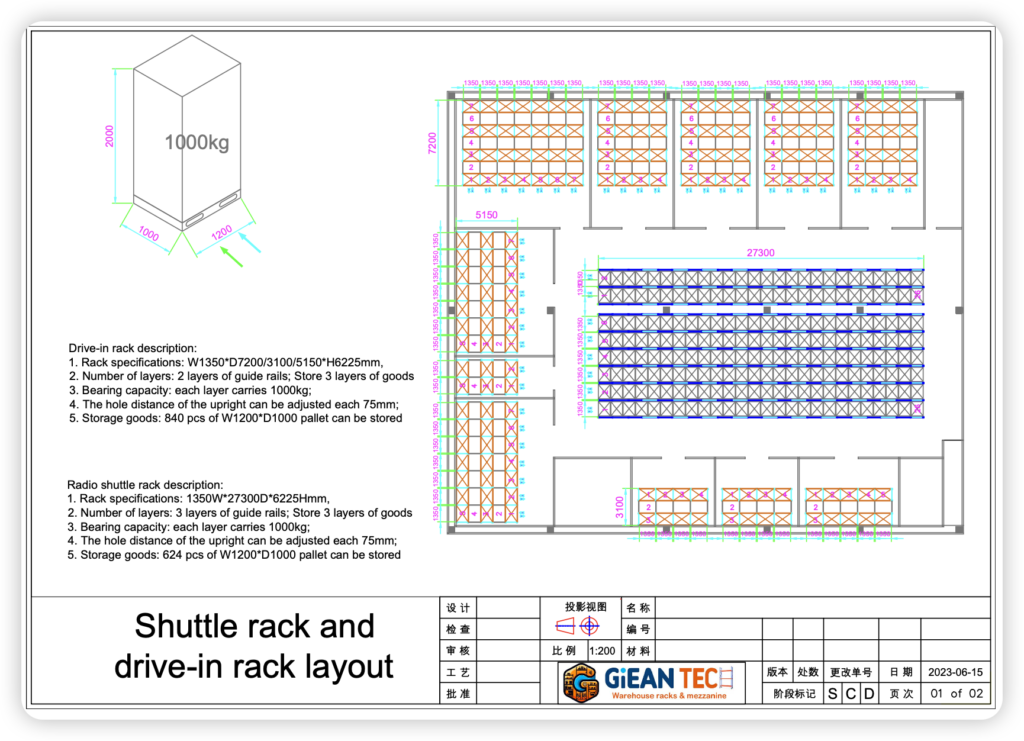

The process of Giean shuttle racking system drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

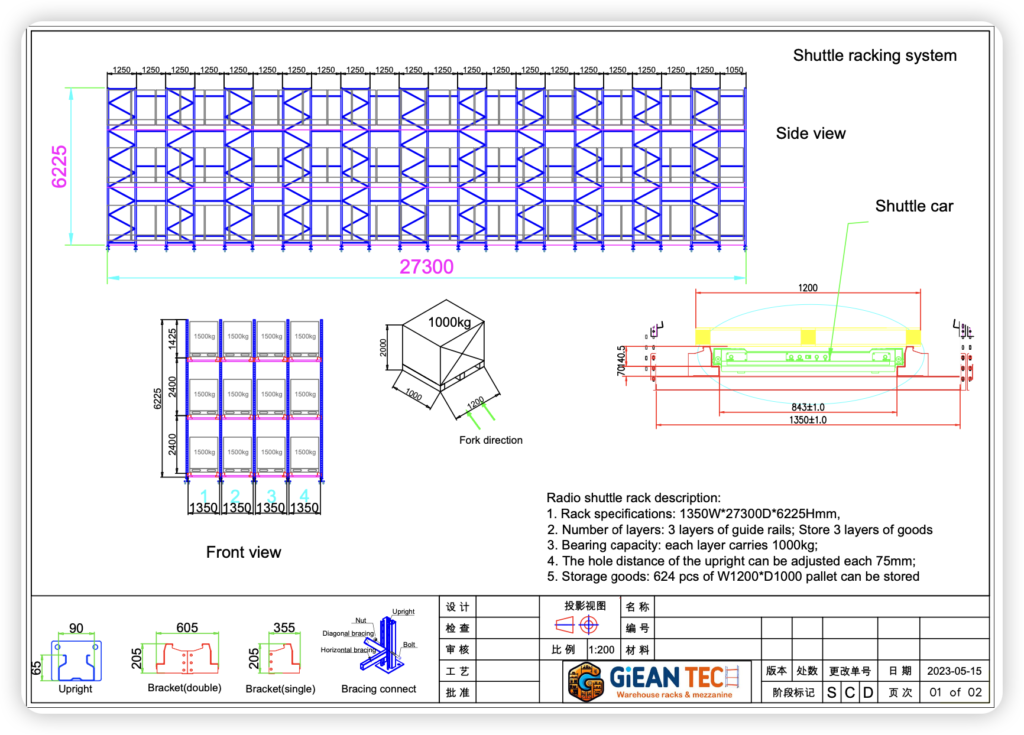

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

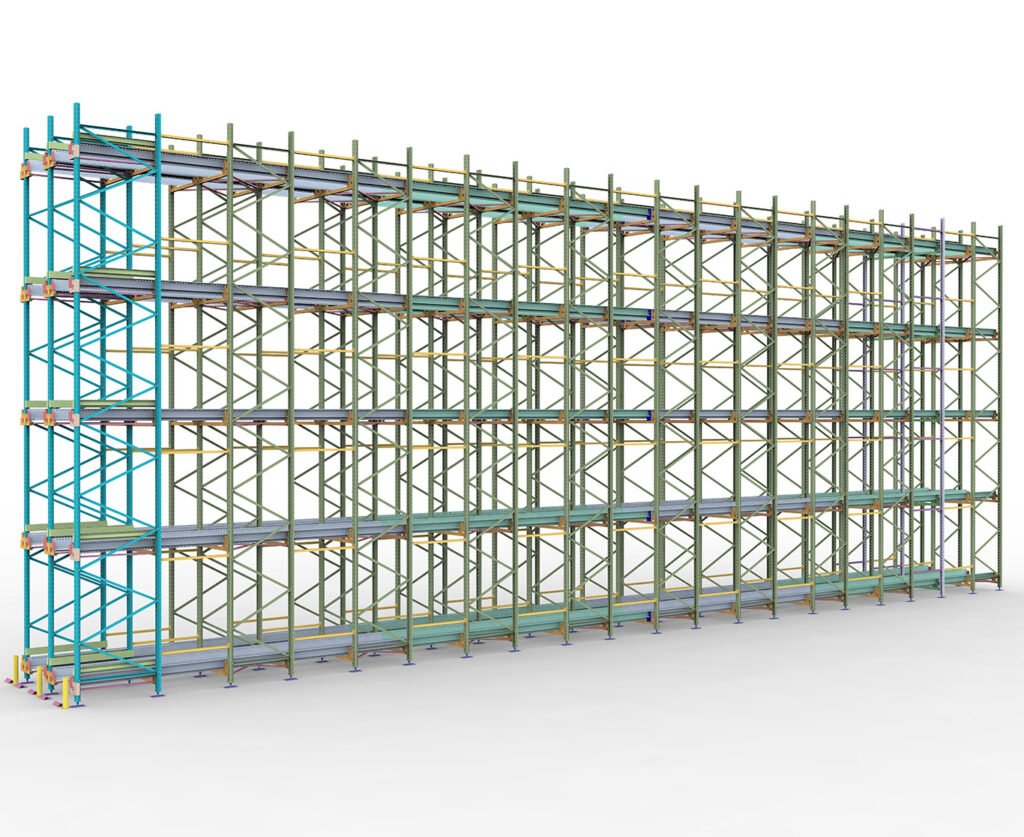

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Custom shuttle racking system

Giean racking, as a leading shuttle racking system manufacturer in China, has been producing and selling shuttle racking system for more than 16 years. We can provide customized shuttle racking system solutions to meet the storage needs of companies with batch goods and improve the utilization of their warehouses. Our shuttle racking system products have passed ISO9001, CE, TUV, and AS4084 certifications for load capacity and reliable quality. Moreover, China is a vast country with abundant labor resources, so sourcing shuttle racking system from China can save you money.

Application Of shuttle racking system

E-Commerce Warehouse

In the E-Commerce industry, fast order processing speed and large order volume are significant characteristics. The shuttle rack system can pick goods quickly and accurately, improving distribution efficiency. It uses pallet unit goods, whole board unit goods or box-type unit goods for storage, by optimizing the arrangement of goods, to achieve high-density storage, effectively improve the utilization of warehouse space, reduce storage costs. At the same time, as the core equipment of the rack system, the shuttle can automatically complete the access to the goods, reduce the manual labor intensity and improve the work efficiency.

Manufacturing Warehouse

The manufacturing industry has a high demand for storage of raw materials and semi-finished products, and often requires the ability to pick and distribute quickly. Shuttle racks can meet the needs of its high-density storage, and combined with the storage management system, to achieve the information management of raw materials and semi-finished products, improving production efficiency. In addition, the stability of the shuttle racks is strong, the use of high-strength steel manufacturing, stable structure, strong carrying capacity, can meet the storage needs of all kinds of goods.

cold storage environment

Shuttle racks can also operate normally in low temperature environment, suitable for cold storage, to ensure the quality of goods and storage efficiency. In warehouses that require low-temperature storage, such as cold storage, frozen warehouses, etc., shuttle racks can reduce low-temperature operation time and improve work efficiency and safety. This is particularly important for industries such as food and beverages, where goods often need to be kept at low temperatures to extend rack life.

Frequently Asked Questions About Shuttle Racking System

Shuttle racks compared with traditional racks, the main advantages are its high-density storage capacity, automated operation efficiency, high space utilization and reduce manual operation errors. The shuttle operates automatically on the rack track, enabling quick access to goods while reducing the waste of warehouse space.

The carrying capacity of shuttle racks mainly depends on the material, structure and design of the racks. In general, shuttle racks made of high-strength steel can carry heavier goods, with carrying capacity ranging from a few tons to dozens of tons. The specific carrying capacity needs to be customized according to the actual needs of customers.

Shuttle rack has a high degree of automation. The shuttle can automatically complete the access of goods, and can be integrated with the warehouse management system (WMS) to achieve information management of goods. In addition, the shuttle can be equipped with sensors and navigation systems to ensure accurate operation on the rack track.

Shuttle racks are suitable for many industries, including e-commerce, manufacturing, cold chain logistics and so on. These industries usually have high requirements for the storage and picking efficiency of goods, and shuttle racks can meet their needs for high-density storage and fast picking.

The maintenance cost of shuttle racks is relatively low. Due to the stable rack structure, and the shuttle uses advanced control system and sensor technology, the failure rate is low. At the same time, the maintenance of racks and shuttles is relatively simple, and the service life can be extended by regular inspection and maintenance.

Shuttle rack has good expansibility. When warehouse space or storage needs change, you can adapt to new storage needs by increasing the number of rack layers, adjusting the layout of racks, or increasing the number of shuttles.

Shuttle rack has high safety. The rack structure is stable and can withstand large loads. The shuttle uses advanced control systems and sensor technology to accurately identify obstacles and avoid collisions. At the same time, the racks and shuttles can also be equipped with safety devices and emergency stop buttons to ensure rapid shutdown and protect personnel safety in emergency situations.

Choose the right shuttle rack supplier need to consider a number of factors, including the supplier’s qualification, experience, technical strength, product quality, after-sales service and so on. It is recommended that customers conduct site visits and comparisons when selecting suppliers to understand their success stories and customer feedback to ensure that they choose the right shuttle rack supplier.