Stacking Racking System

What Is Stacking Racking System

The stacking rack is a handling equipment derived from the pallet, which integrates the functions of the steel pallet and the rack. It can not only carry goods like a pallet, but also has the ability to stack, and can be stacked in multiple layers to form a three-dimensional storage mode. The stacking rack system usually consists of multiple stack rack units, which can be flexibly combined and arranged according to needs.

Customizable Stacking Racking System

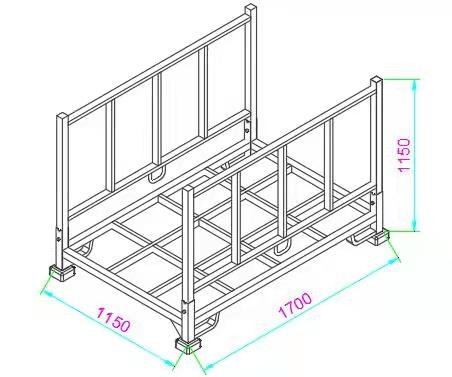

The width of the stacking rack is common in 1200mm, 1700mm, 2200mm, 2700mm, 3600mm and other specifications, the depth is common in 800mm, 1000mm, 1200mm, etc., and the common height is 1200mm, 1500mm, 1800mm, 2000mm, 2400mm, etc. The number of layers stacked is also an important factor to consider when designing. The common number of layers is 2, 3, 4 layers, etc., in addition to the above sizes, Giean also supports customized sizes.

The Process Of Giean Warehouse Storage Solution Drawing Design

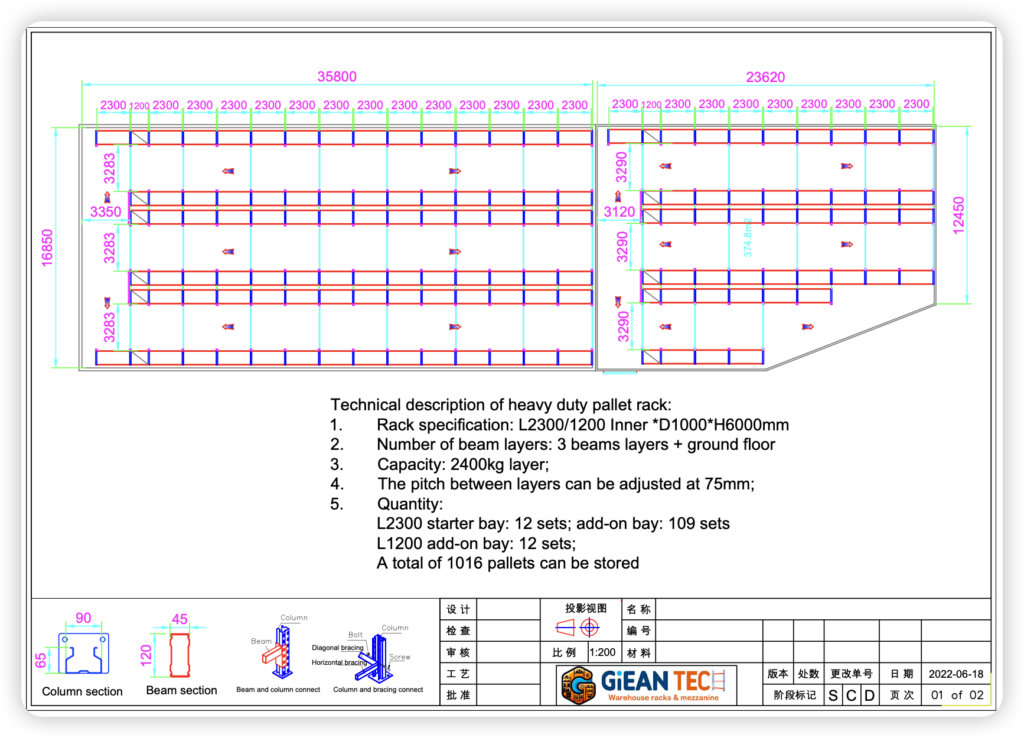

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

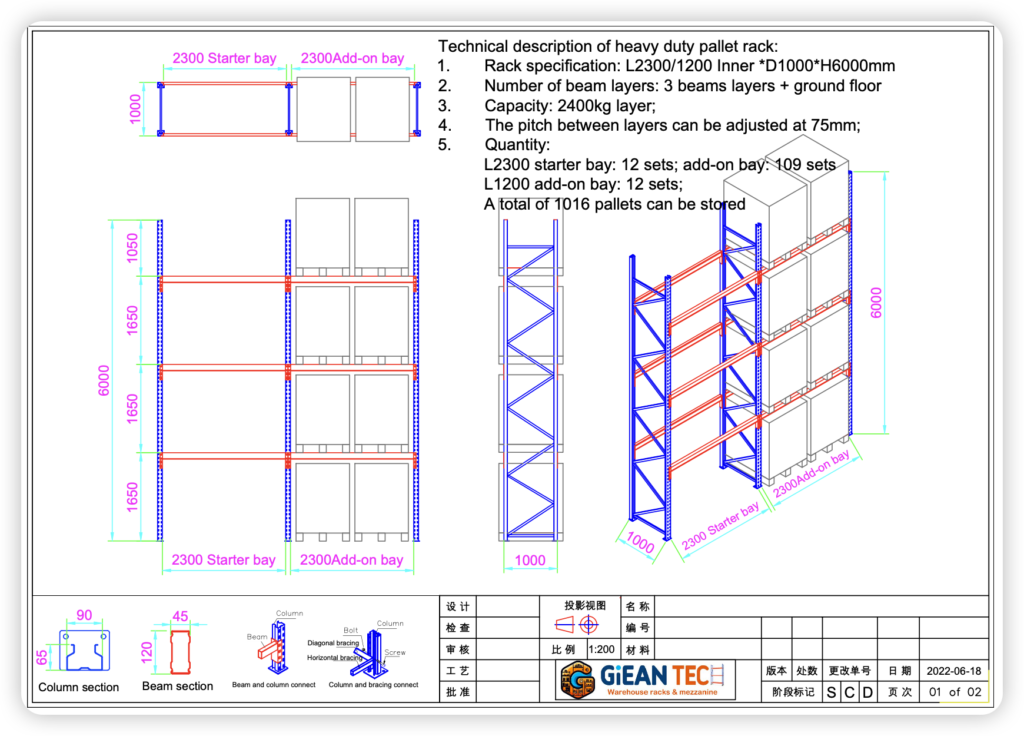

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

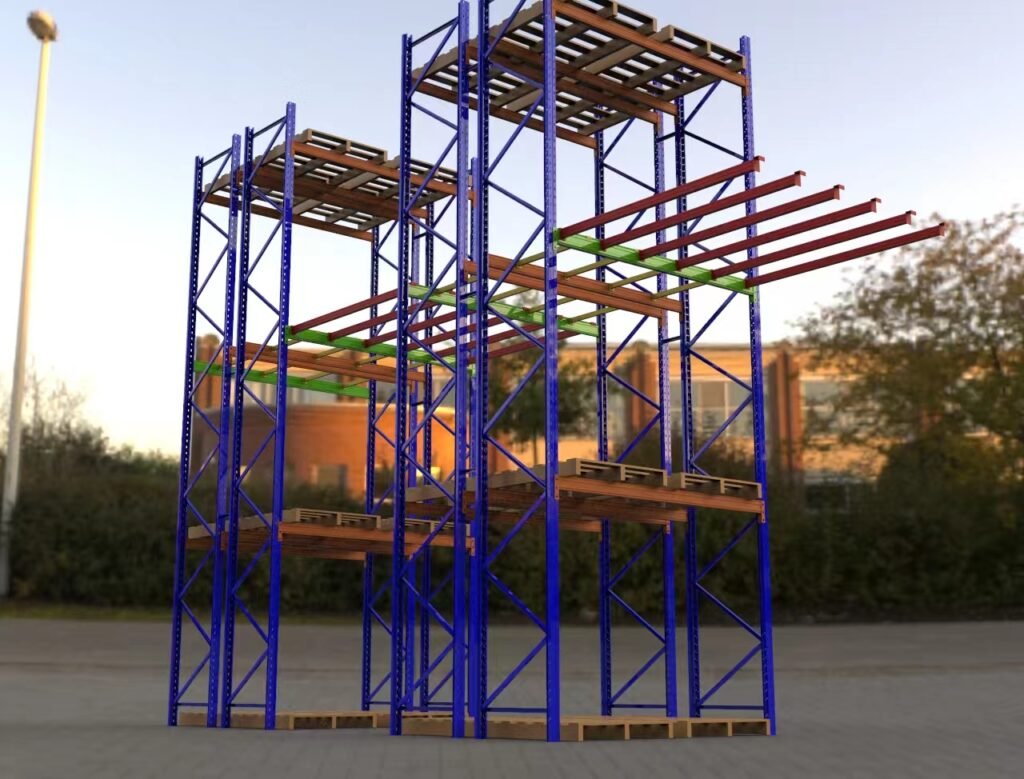

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Stacking Racking System

1.Improve space utilization: Stacking racks can use vertical space to stack goods along the vertical direction, thereby improving warehouse space utilization and saving storage space. This three-dimensional storage mode does not require additional racks, storage cages and other equipment, and is suitable for use in limited space environments such as rental warehouses, low vintage warehouses or workshop temporary storage areas.

2.Enhanced cargo security: Stacking racks can support and protect goods well, reducing the risk of damage and loss of goods. In transit, the stacking rack can effectively protect the goods from damage and ensure the safe arrival of the goods at the destination.

3.Adaptable: The stacking rack can be customized and adjusted according to different cargo types, sizes and weights to meet different storage needs. In addition, the stacking rack can also be freely shelved according to the site condition, convenient and flexible.

4.Easy storage and management: The stacking rack can classify, organize and mark the goods, making the goods easy to store and manage. The goods are lined and stacked along the walkway and channel, arranged neatly and orderly, which is convenient for counting, delivery and warehouse inventory. At the same time, the stacking shape of the stacking rack is suitable for the nature and characteristics of the goods, which is convenient for the custody and maintenance of the goods, and is conducive to the first-in-first-out of the goods.

5.Improve transportation efficiency: The use of stacking racks can reduce the warehouse footprint and improve the storage density of goods, thereby improving the transportation efficiency of goods. With mechanized handling equipment, such as forklifts, stacking racks can be used in transportation, handling, loading, unloading, storage and other links to reduce operations and improve operational efficiency.

6.Cost saving: The use of stacking racks can reduce investment in equipment such as racks and reduce warehousing costs. At the same time, because the stacking rack can improve space utilization and transportation efficiency, it can also indirectly reduce logistics costs.

Classification Of Stacking Racking System

High flexibility: The folding stacking rack can be folded up for storage when not in use, saving space.

Easy to handle: the folded stacking rack is light in weight and small in size, which is easy to handle and move.

A variety of types: including collapsible stacking rack, assembled stacking rack etc., to meet different needs.

Application scenario:

1.Suitable for places that require frequent changes in layout or storage space.

2.Suitable for storing goods of irregular shape or variable size.

Flexible structure: The removable stacking rack consists of multiple components that can be assembled and disassembled as needed.

Easy installation: The installation process is simple and quick, without complex tools and equipment.

Lower cost: Compared to the fixed stacking rack, the cost of assembled stacking rack is lower.

Application scenario:

1.Suitable for temporary storage or short-term use.

2.Suitable for small and medium-sized enterprises or warehouses with certain cost requirements.

Stable structure: The fixed stacking rack is usually welded by section steel, which has a strong and durable structure and strong bearing capacity.

High space utilization: Multiple layers can be stacked to form a three-dimensional storage mode, without the need for additional racks and other equipment to improve the utilization of warehouse space.

Easy to manage: unified specifications, fixed capacity, storage of goods at a glance, easy to inventory and management of the warehouse.

Strong adaptability: Can be customized according to the size and weight of different goods, strong adaptability.

Application scenario:

1.Suitable for limited space environments such as rental warehouses, low vintage warehouses or workshop temporary storage areas.

2.It is suitable for stacking and turnover of finished products with large storage quantity, single outline size, large volume and light weight.

Frequently Asked Questions About Selective Pallet Racking System

The main advantage of the stacking rack system is its efficient storage capacity and space utilization. By stacking vertically, storage density can be significantly increased and footprint reduced. In addition, automated stacking systems improve access efficiency, reduce manual operations, reduce error rates, and help with inventory management and tracking.

The stacking rack system is widely used in various types of warehouses, especially those that need to store a large number of goods and have high space utilization requirements, such as manufacturing warehouses, distribution centers, cold chain logistics, etc. It is also suitable for storing heavy, large size or irregularly shaped goods.

The safety of the stacking rack system is guaranteed through many aspects. First of all, the rack structure needs to undergo strict mechanical calculations and tests to ensure its load-bearing capacity and stability. Secondly, the automated stacking equipment is equipped with safety sensors, emergency stop devices, etc., to prevent accidents. In addition, regular maintenance and inspection is also an important part of ensuring safety.

Choosing the right stacking system takes into account a number of factors, including the type, size and weight of the goods to be stored, the size of the warehouse space, height constraints, and budget and operational requirements. It is recommended to cooperate with a professional rack supplier or system integrator for detailed requirements analysis and program customization.

The return on investment of a stacking racking system depends on a number of factors, such as improved storage efficiency, reduced labor costs, faster cargo turnover, and so on. Often, by improving the overall operational efficiency of the warehouse, the stacking racking system can achieve a return on investment in a relatively short period of time. However, the specific rate of return needs to be assessed according to the actual situation.

The maintenance and maintenance points of the stacking rack system include regularly checking whether the rack structure is stable, whether the connector is loose, timely cleaning the dust and debris on the rack, keeping the rack dry and ventilated, and preventing corrosion and damage. For automated stacking equipment, it is also necessary to regularly check and replace the wearing parts to ensure the normal operation of the equipment.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!