Medium Duty Racking System

What Is Medium Duty Racking System

Medium duty racking system is a kind of storage equipment system, mainly used to store and manage medium weight goods, medium duty racking system is named according to the carrying capacity of the rack, its carrying capacity between light racks and heavy racks, usually the rack carrying capacity between 150kg~800kg/ layer, However, the specific load capacity may vary depending on the design and material. The difference between it and the light duty rack is that its column is fixed with bolts, and the column of the light duty is a welded structure

Customizable Medium Duty Racking System

We have prepared for you some common medium duty racking system sizes in the table for your reference.

| Rack Size(mm) | Color | Layer | Load Capacity |

|---|---|---|---|

| L2000*D600*H2000 | Orange+Blue | 1-4 levels | 200-800KG |

| L2000*D600*H2500 | Orange+Blue | 1-4 levels | 200-800KG |

| L2000*D600*H3000 | Orange+Blue | 1-5 levels | 200-800KG |

| Customizable | Orange+Blue | 1-8 levels | 200-1000KG |

The process of Giean warehouse storage solution drawing design

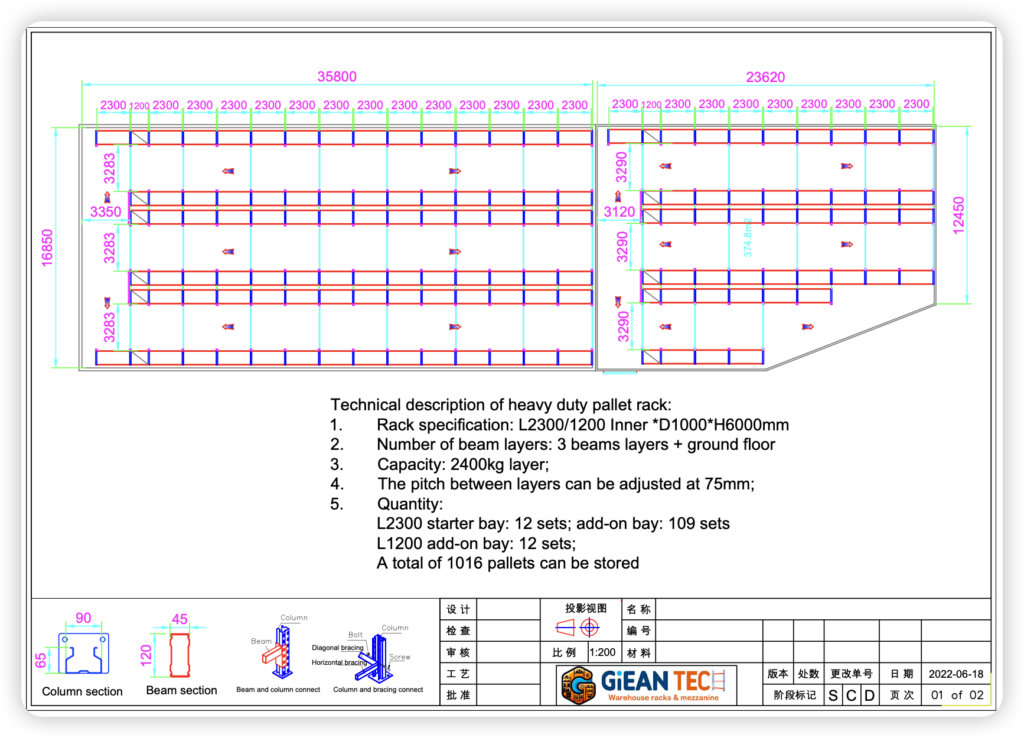

Warehouse Layout Design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

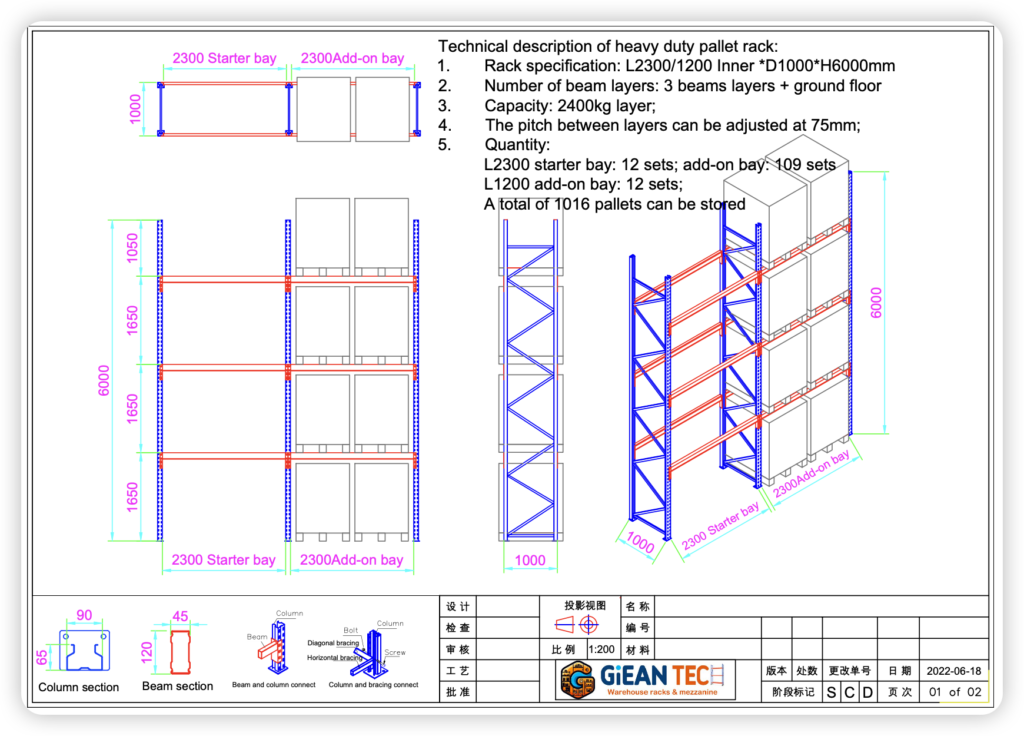

Racking Structure Design

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

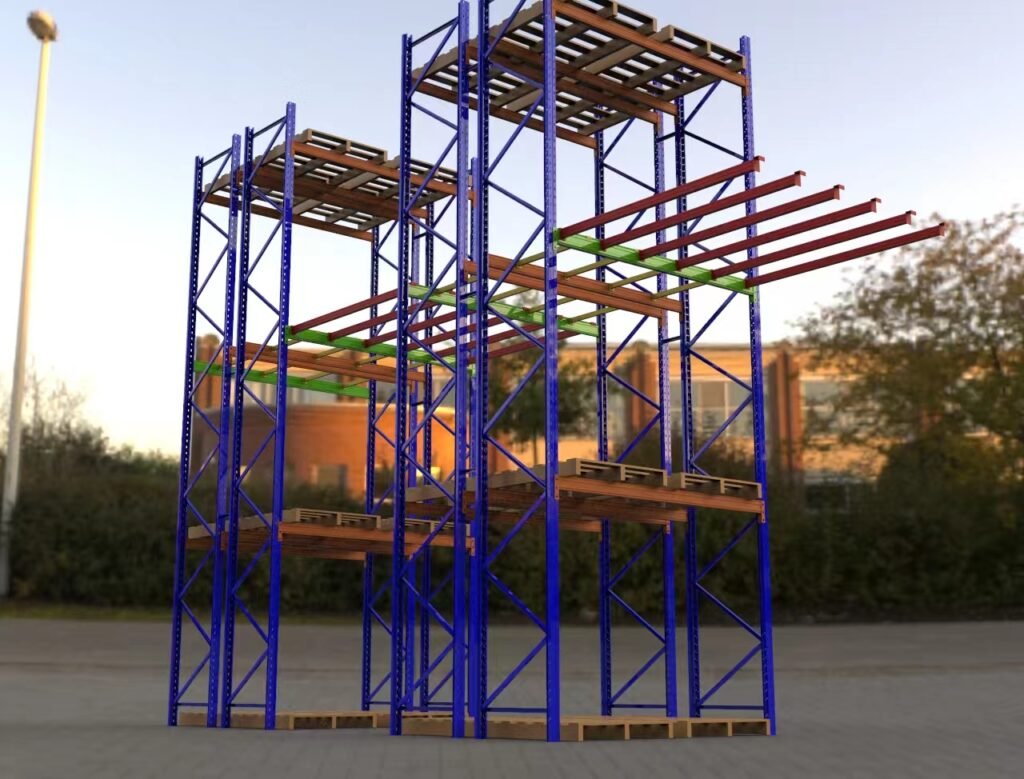

3D rendering design

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Medium Duty Racking System

1.Strong load-bearing capacity: Medium duty rack are usually designed to carry medium-weight cargo, and their construction and material selection are carefully considered to ensure that they can withstand the predetermined load. This makes them ideal for storing heavy goods.

2.High space utilization: Medium duty rack are designed to maximize the utilization of storage space. By stacking goods vertically, they can significantly reduce the footprint of floor space, thereby increasing the capacity of a warehouse or storage area. In addition, the aisles between the racks can also be optimized to reduce walking space and further improve space efficiency.

3.High flexibility: Medium duty rack can often be customized and adjusted according to storage needs. Whether it is the height, width, depth of the rack, or the number and spacing of the shelf, it can be flexibly configured according to actual needs. This flexibility allows the medium duty rack to adapt to a variety of different types of storage environments and goods.

4.Easy to manage and maintain: the structure of the medium duty rack is clear and the layout is reasonable, making the access and management of the goods easy. At the same time, the maintenance and maintenance of the rack is also relatively simple, such as cleaning, inspection and replacement of damaged parts, etc., can be completed quickly and efficiently.

5.Improve operational efficiency: The use of medium duty rack can optimize the storage and retrieval process of goods. Goods are placed on shelves in an orderly manner, allowing employees to find the goods they need more quickly, reducing search and handling time. In addition, the racks can also be used in conjunction with automated equipment and systems (such as forklifts, stackers, etc.) to further improve operational efficiency.

6.Protect the goods: The medium duty rack provides a stable and safe storage environment for the goods. Goods are placed on shelves to reduce the chance of contact with the ground, thereby reducing the risk of moisture, damage or contamination. In addition, the shelf layer usually has anti-slip, anti-corrosion and other characteristics, which can better protect the goods.

7.High cost effectiveness: Although the initial investment of medium duty rack is relatively high, considering the benefits of improved space utilization, improved operational efficiency and cargo protection, its cost effectiveness is very high in the long run. In addition, the durability of the medium duty rack is also very strong, can be used for a long time without frequent replacement.

Application Of Medium Duty Racking System

Warehousing Storage

Main Applications: Medium duty racks play an important role in warehouse storage, especially for storing a large number of medium-weight goods. It can effectively use space, improve storage efficiency, and facilitate the access and transportation of goods.

Advantages: Through reasonable layout and planning, medium duty racks can significantly improve the storage capacity of the warehouse and the accessibility of goods, helping to reduce the risk of inventory overstocking and damage to goods.

Distribution Center

Application: In the distribution center, the medium duty rack can effectively classify and sort the goods, improve the sorting efficiency.

Advantage: With clear cargo classification and labeling, medium duty rack help reduce sorting errors and delays, ensuring that goods reach customers accurately and in a timely manner.

Laboratory Storage

Applicable environment: For laboratories that require strict environmental control, such as chemical laboratories or biological laboratories, medium duty rack can provide appropriate storage space.

Features: The stability and adjustability of the medium duty rack make it able to adapt to the special needs of the laboratory to ensure the safe storage and orderly management of experimental items.

Other Industry Applications

Retail: Medium duty rack are also widely used in retail places such as shopping malls and supermarkets to display and store goods and improve customers’ shopping experience.

Manufacturing: In the manufacturing industry, medium duty rack can be used to store raw materials, semi-finished products and finished products to achieve a smooth connection of the production process.

Logistics industry: The logistics industry is also inseparable from the support of medium duty rack, which can help logistics enterprises achieve orderly storage and rapid sorting of goods, improve logistics efficiency and service quality.

Frequently Asked Questions About Medium Duty Racking System

First of all, it is crucial to clarify the maximum weight of the items you need to store. The load-bearing capacity of different materials (such as cold-rolled steel, aluminum alloy, etc.) and designs varies greatly. Ensure that the load-bearing capacity of the selected rack meets or exceeds your actual needs to ensure safe use.

According to the space size of the warehouse or storage area, choose the appropriate rack size and height. Consider the width of the channel between the racks, so that employees can easily access the goods, but also consider the height of the warehouse limit, to avoid too high access inconvenience or security risks.

As your business evolves, your storage needs may change. Therefore, asking whether the rack supports shelf height adjustment, whether it is easy to reconfigure or expand, and whether it supports different types of accessories (such as hooks, grid panels, etc.) for added flexibility are all important considerations.

Understand the installation process of the rack, whether a professional team is required for installation, and subsequent maintenance requirements. Some racking systems may be designed to be easy to install themselves and maintain daily, which can save costs and time.

In addition to the purchase cost of the rack itself, it is also necessary to consider the economic benefits of its long-term use. This includes installation costs, transportation costs, maintenance costs, and potential space savings or operational efficiency benefits from increased storage efficiency. Compare the price/performance ratio of different brands and models to choose the best solution for your budget and needs.

Ensure that the selected racking system complies with industry standards and safety specifications, such as ISO certification, CE marking, etc. Reliable products not only reduce the risk of problems during use, but also guarantee the safety of employees. At the same time, understanding the after-sales service provided by the supplier, such as warranty period, technical support, etc., is also an important part of the guarantee investment.