Mezzanine Racking

What Is Mezzanine Racking

Mezzanine racking is a simple rack system that makes full use of the upper space of the warehouse:

Definition: Mezzanine racking is a racking system that builds an intermediate attic on an existing rack or work site to increase the storage area.

Features:

Space utilization: By building the middle mezzanine, the upper floor space of the warehouse or work site is effectively utilized and the storage capacity is increased.

Flexibility: The mezzanine racking system can be customized according to the actual needs, including the number of floors of the mezzanine, size, load-bearing capacity, etc.

Applicability: Suitable for storing light bubbles and small and medium-sized goods, or long storage period of goods.

What is the size of mezzanine racking system

The dimensions of mezzanine racking can be designed according to specific needs and warehouse space, but usually follow certain standards. Here are some of the specifications we recommend for you

| Item | Specification |

|---|---|

| Height | 2000-12000mm or as request |

| Depth | 2000-10000mm or as request |

| Width | 2000-10000mm or as request |

| Load capacity | 500 kg-2000 kg per layer |

| Colors | Blue, safety orange and computer grey or customized |

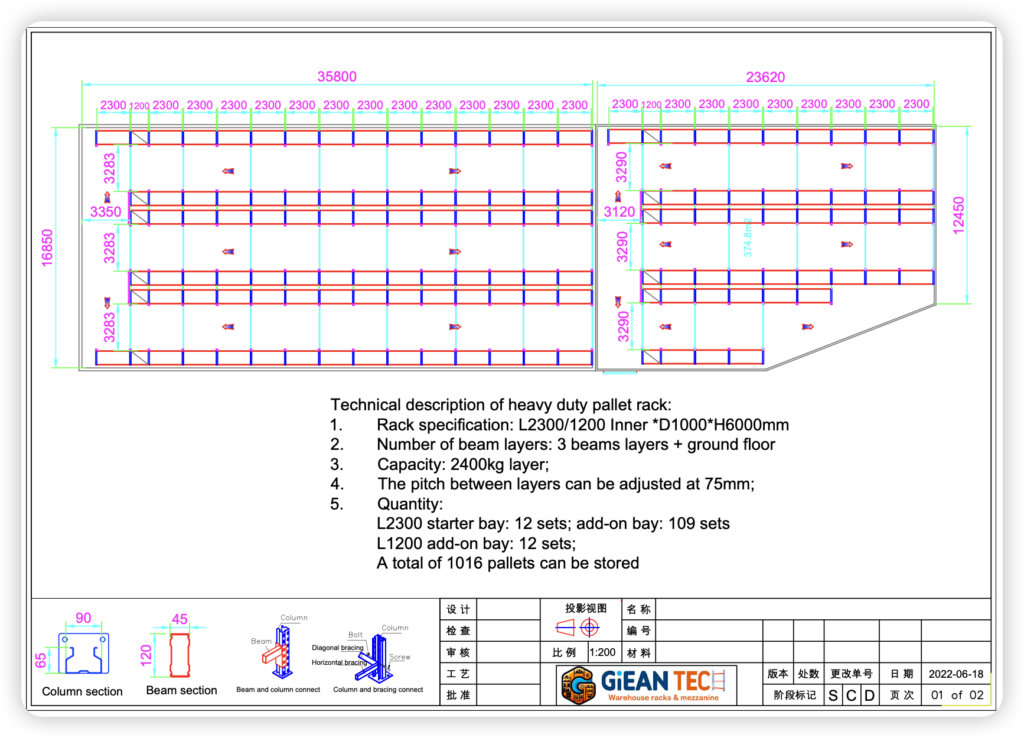

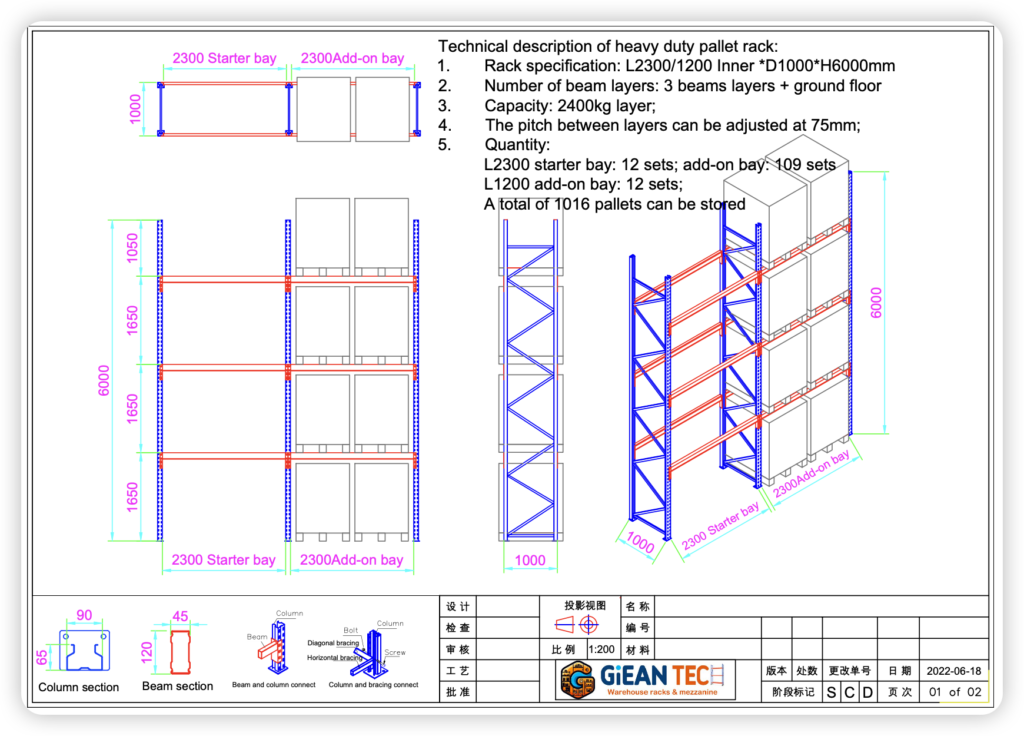

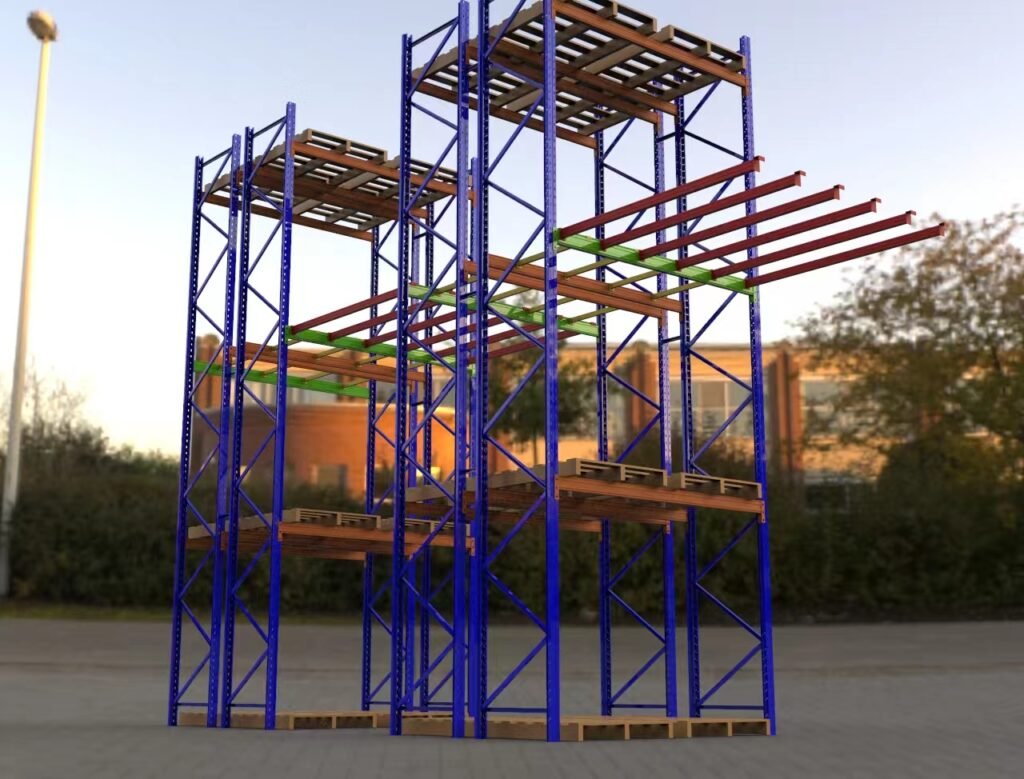

The process of Giean warehouse storage solution drawing design

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Mezzanine Racking System

1. High space utilization rate

Vertical space utilization: Mezzanine racking maximizes vertical space by placing racks above warehouses or industrial sites, thus providing additional storage space. This design is especially suitable for scenarios where the warehouse area is limited but the storage capacity needs to be increased.

Multi-layer design: Mezzanine racking can be designed into two or three layers, or even more layers, each layer can store goods, greatly improving space utilization.

2. High storage efficiency

Classified storage: Mezzanine racking can be partitioned and classified according to the type, size and weight of the goods, making the access to the goods more efficient and orderly.

Rapid access: Through reasonable rack layout and organization, mezzanine racking can achieve rapid access to goods. At the same time, it can also be equipped with sliding rails, tackles and other devices to further facilitate the access of goods.

3. Good management effect

Accurate inventory: The identification and coding system on the mezzanine racking, as well as visual management software, make it easier for warehouse managers to carry out accurate inventory.

Fast positioning: Through the identification and coding on the rack, managers can quickly locate the required goods, improving the accuracy and efficiency of warehouse management.

4. Strong flexibility

Customized design: Mezzanine racking can be customized according to the actual needs and warehouse space, including the size of the shelves, the number of layers, load-bearing capacity, etc., to meet the storage needs of different scenarios.

Adaptable: Mezzanine racking are suitable for a wide range of cargo types and storage needs, including light, medium and heavy cargo storage. At the same time, it can also be flexibly adjusted according to the changes of goods.

5. High security

Stable structure: The mezzanine racking uses high-strength materials and stable structural design to ensure the load-bearing capacity and stability of the rack.

Safety devices: The racks can also be equipped with safety devices such as anti-slip pads and anti-overturning devices to ensure the safe storage of goods and the safe operation of staff.

6. Good cost effectiveness

Saving space: By improving space utilization, mezzanine racking can reduce the need for warehouse space, thereby saving rent or construction costs.

Long-term benefits: Although the initial investment of mezzanine racking may be higher, the long-term storage benefits and management efficiency improvements it brings will bring greater economic returns to the enterprise.

Application Of Mezzanine Racking System

Features: There are often a large number of parts in the factory or workshop that need to be stored, and these parts are of various types and sizes. Mezzanine rack can store parts by type and size for easy daily use and management.

Advantages: Improve storage efficiency, reduce the floor space occupation, make the workshop more tidy and orderly.

Features: In addition to large goods in the warehouse, it is often necessary to store office supplies, tools and other small items. These items are large in number and small in size, and it is more appropriate to use mezzanine racking for storage.

Advantages: Easy classification management, improve storage density, reduce warehouse area occupation.

Auto parts: There are many kinds of auto parts, and most of them are small and medium-sized items, and mezzanine racking are very suitable for storing these parts.

Auto 4S shop: Auto 4S shop needs to store a large number of auto parts and accessories, mezzanine racking can provide sufficient storage space, and easy to manage and access.

Light industry, electronics and other industries: the products of these industries are mostly light bubbles and small and medium-sized goods, and need a variety of small batch storage methods, mezzanine racking just meet these needs.

Frequently Asked Questions About Mezzanine Racking System

Mezzanine racking can significantly increase storage space, and the percentage increase depends on the height of the warehouse, the existing layout, and the design of the mezzanine racking. Often, mezzanine racking can provide 50% to 100% or more additional storage space without increasing the floor area of the warehouse.

The load-bearing capacity of mezzanine racking depends on a number of factors, including the materials used (such as the size and thickness of steel), the structural design, and the quality of the installation. In general, professional Mezzanine racking systems can be designed to carry weights ranging from several hundred kilograms to several tons to meet the storage needs of different goods.

Installation time depends on the size of the warehouse, the complexity of the mezzanine racking, and the experience of the installation team. For small and medium-sized warehouses, the installation can usually be completed in a few days to a week. Large or complex projects may take longer.

The design of mezzanine racking should take into account the daily operation process of the warehouse, including the warehousing, storage, picking and discharging of goods. Proper layout and design can optimize these processes and improve the operational efficiency of the warehouse. At the same time, stairs and cargo lifting equipment for mezzanine racking (such as lifts or slides) should be easy for employees to use to reduce labor intensity and improve efficiency.

The safety of mezzanine racking is the primary consideration. The professional mezzanine racking system should comply with the relevant safety standards and specifications, including structural design, material selection, installation process and so on. In addition, regular safety checks and maintenance are also important measures to ensure safety.

Mezzanine racking are highly customized and can be designed and manufactured according to the specific situation of the warehouse and customer needs. Including the size of the racks, the number of layers, the load-bearing capacity, the configuration of stairs and cargo lifting equipment can be customized according to actual needs.

The design of mezzanine racking should take into account the ventilation and lighting needs of the warehouse. Proper layout and design can ensure adequate air circulation and light to avoid moisture or mold on the goods. At the same time, lighting can be installed as needed to ensure adequate lighting in the mezzanine racking area.

Mezzanine racking have relatively low maintenance costs. In general, regular inspection of rack stability, cleaning of rack surfaces and replacement of worn parts are the main maintenance work. In addition, reasonable use and maintenance can extend the service life of the rack and reduce long-term costs. If you choose a reliable quality, reasonable design of the mezzanine racking system, its maintenance costs will be more controllable.

Leave Your Email And Our Latest Catalogue Will Be Sent To You!