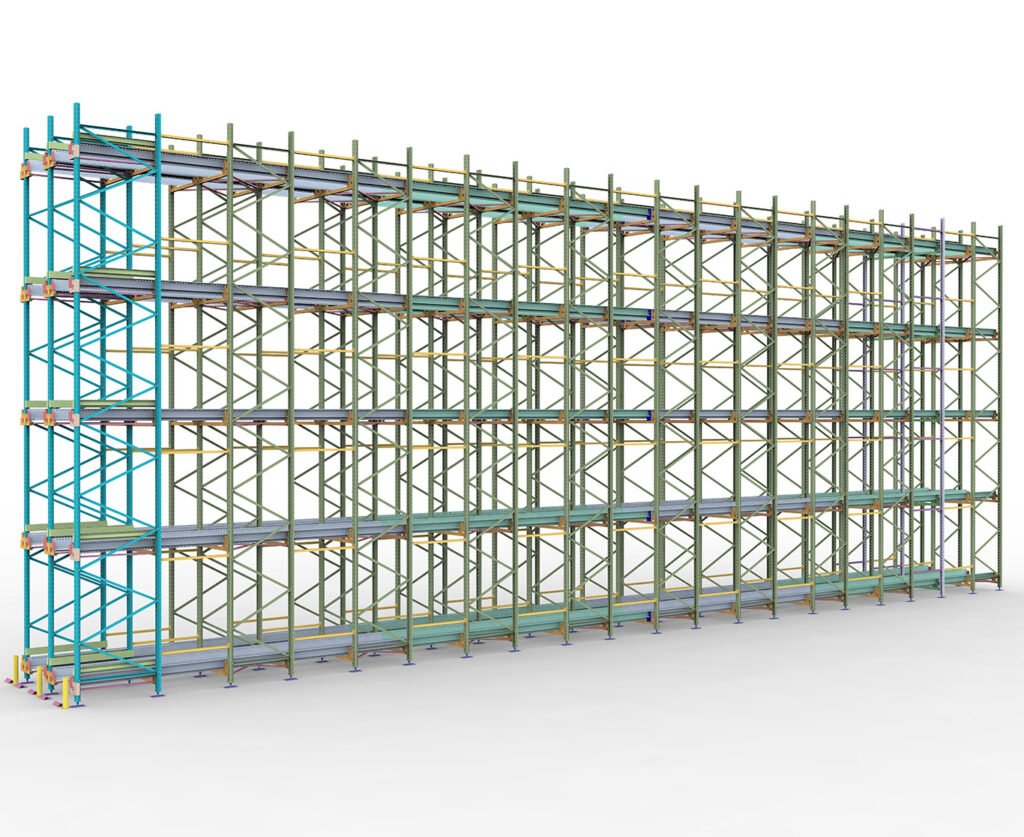

4 Way Shuttle Racking System

What Is 4 Way Shuttle Racking System

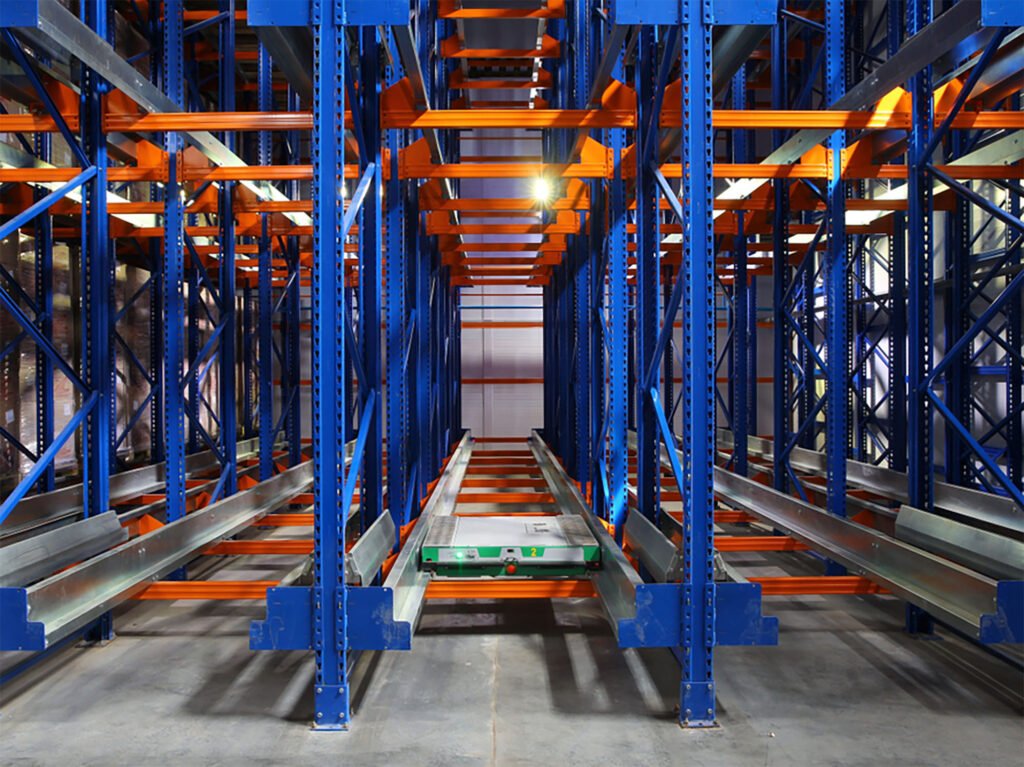

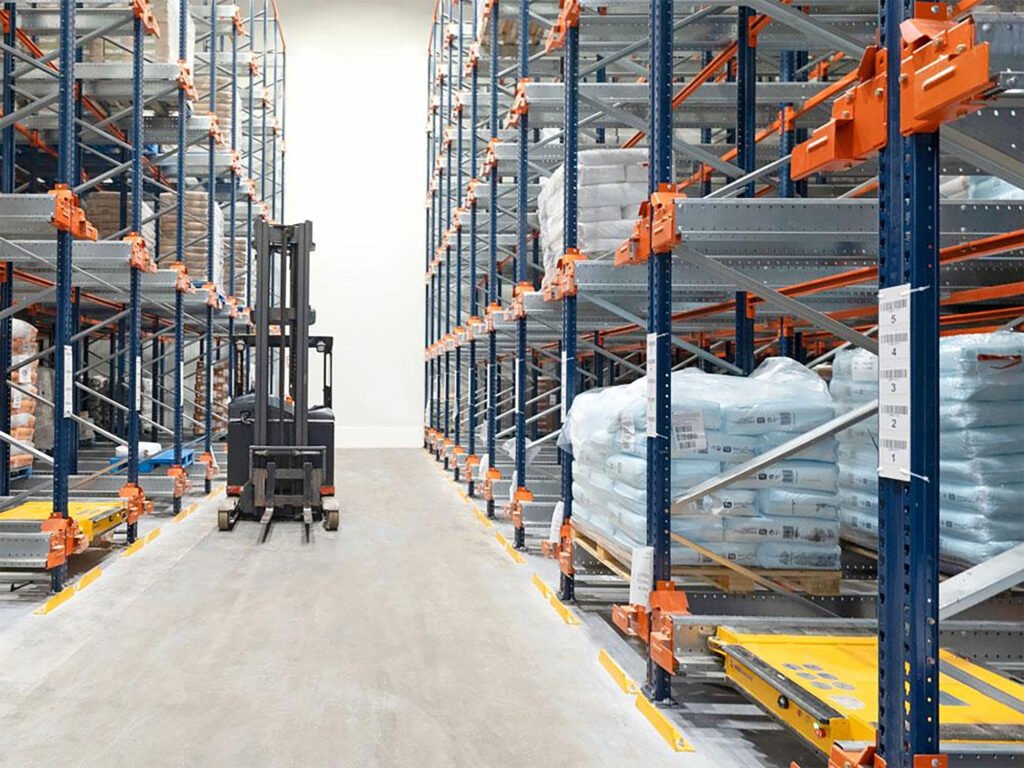

The four-way shuttle racking system is a high-density intelligent storage system composed of rack, remote control shuttle and forklift.

System composition:

Rack: the main structure used to store goods.

Shuttle vehicles: can travel in four directions on the rack track to achieve the access and handling of goods.

Elevator: used in conjunction with the shuttle vehicles to achieve the transfer of goods.

Control system: including WMS (warehouse management system), WCS (warehouse control system) and other software, used to monitor and schedule the operating status of the equipment inside the shelf system.

4 Way Shuttle racking main features

Compact structure: the height and size are small, which can save more storage space and improve storage capacity.

Strong flexibility: The shuttle can travel in four directions on the rack track to achieve one-stop point-to-point transportation to any cargo location on the warehouse floor.

High utilization rate of storage space: no need to cooperate with forklifts and other equipment to complete the operation independently, cancel the forklift channel, make the rack structure more dense, and effectively improve the utilization rate of storage space.

Dynamic location management: It can be organically connected with the production links outside the warehouse to achieve dynamic management of goods.

Intelligent control: with automatic and semi-automatic two modes of work, greatly improve the efficiency of goods access and warehouse space utilization.

The process of Giean 4 Way shuttle racking system drawing design

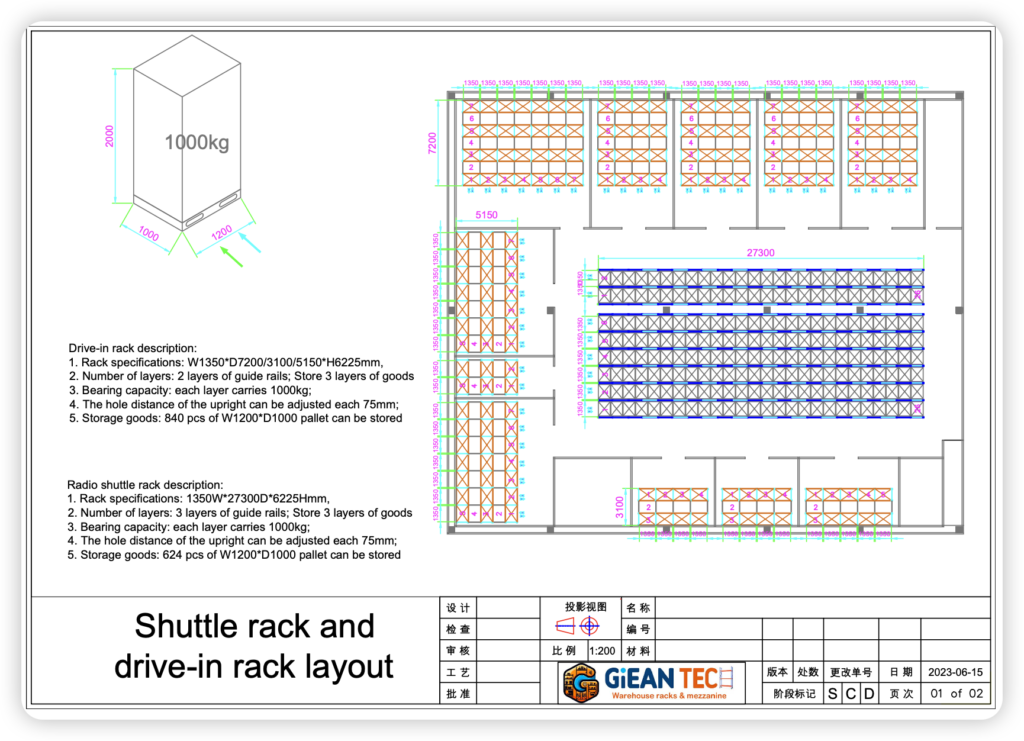

Firstly, we need to determine the size of your warehouse in order to create a space-saving layout drawing tailored to your specific warehouse dimensions.

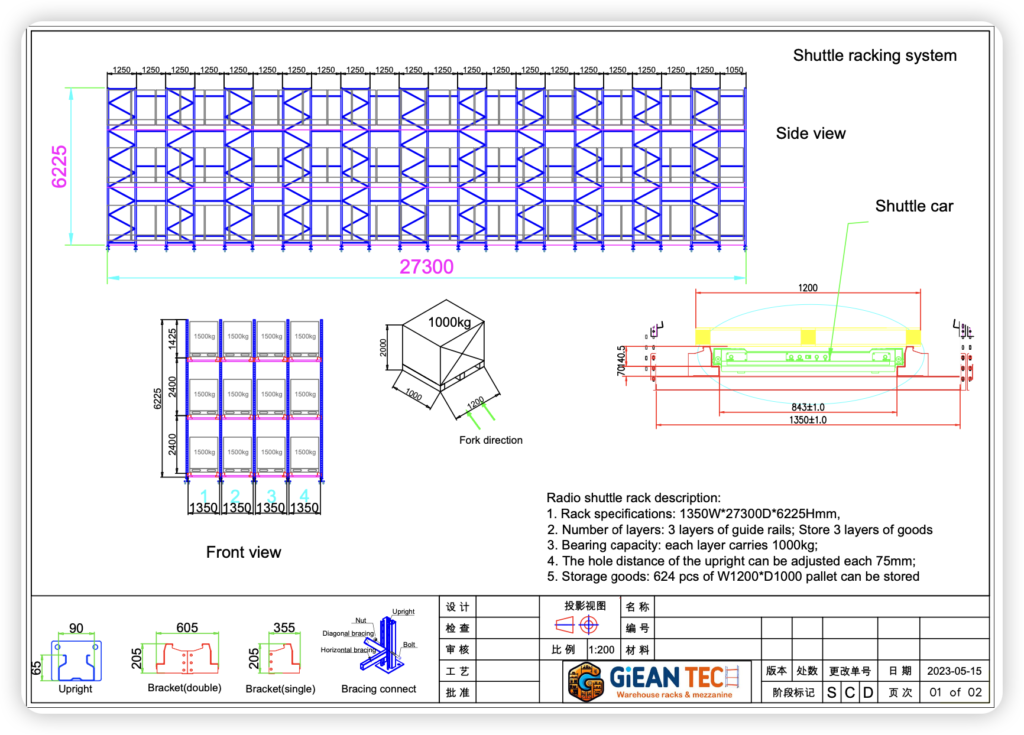

Next, we will design a rack structure diagram, which can more intuitively reflect how you can store and retrieve goods conveniently, quickly and safely.

After confirming the previous drawings, we will create a more three-dimensional 3D drawing based on them to enhance the overall effect.

Why Choose Giean Custom 4 Way shuttle racking system

Giean racking, as a leading 4 way shuttle racking system manufacturer in China, has been producing and selling shuttle racking system for more than 16 years. We can provide customized 4 way shuttle racking system solutions to meet the storage needs of companies with batch goods and improve the utilization of their warehouses. Our 4 way shuttle racking system products have passed ISO9001, CE, TUV, and AS4084 certifications for load capacity and reliable quality. Moreover, China is a vast country with abundant labor resources, so sourcing shuttle racking system from China can save you money.

Application Of 4 way shuttle racking system

Logistics and warehousing:

such as e-commerce warehousing, third-party logistics, food and beverage warehousing, medical warehousing, etc.

Automotive industry:

such as auto parts warehousing.

Retail industry:

such as large retail stores, department stores, etc.

Manufacturing:

Such as parts warehousing, raw material management, finished product warehousing, etc.

Frequently Asked Questions About 4 Way Shuttle Racking System

The 4-way shuttle rack system is an advanced automated storage system that uses shuttle vehicles (or automated guided vehicle AGVs) to move horizontally and vertically in four directions on the rack track to achieve automatic access to goods. This system greatly improves the space utilization rate and operation efficiency of the warehouse.

The main advantages of 4-way shuttle racks compared to traditional racks include: higher storage density (because the shuttle can closely pack the goods), faster access speed (automation reduces manual intervention), better flexibility (the system is easy to expand and adjust), and lower operating costs (automation reduces the need for manpower).

The 4-way shuttle usually uses laser navigation, electromagnetic navigation or visual navigation technology for positioning and navigation. These systems are able to precisely guide the shuttle on the rack track, ensuring that goods are placed and removed accurately.

Safety is one of the key points in the design of 4-way shuttle rack system. The system is usually equipped with emergency stop buttons, obstacle detection sensors, speed control and other safety measures to ensure the safety of personnel and goods during operation.

Although the initial investment in the 4-way shuttle rack system is high, its long-term maintenance costs are relatively low. This is because automated systems reduce human intervention, reducing the risk of human error and damage. In addition, modern shuttle designs typically have a long service life and a lower failure rate.

Yes, the 4-way shuttle rack system can be flexibly adapted to different sizes and weights of goods. By adjusting the configuration of the shuttle and the design of the racks, the system can handle many types of cargo, from light and small to heavy and irregular.

Modern 4-way shuttle racking systems are usually equipped with advanced monitoring and management software. These software can display the status, location and inventory of the shuttle in real time to help managers make efficient decisions and scheduling.

It is for the problem of limited warehouse space, 4 provides an efficient solution to the shuttle rack system. By maximizing rack storage capacity and automating operational efficiency, the system is able to achieve higher storage capacity and faster access speed in limited space.